4118 SeriesHybrid Stepper Motor

- More torque than standard NEMA 17 stepper motors

- Highly customizable

- Cost effective

- NEMA 17 (1.670 in) Frame Size

- 1.8° Step Angle

- 1.34 to 2.34 in Length

- 42.48 to 124.62 oz-in Holding Torque

Models

| Model # | NEMA size | Frame size | Step Angle | Connection Type | Length, in | Current AMP | Holding Torque, oz-in | Resistance | Inertia, oz-in² | Weight, lbs | # of Leads | Availability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4118C-01 | NEMA 17 | 1.670 in | 1.8° | Bipolar | 2.340 in | 2 AMP | 124.62 oz-in | 2 | 0.56 oz-in² | 0.902 lbs | 4 | Online |

| 4118L-07P | NEMA 17 | 1.670 in | 1.8° | Parallel | 1.890 in | 2.1 AMP | 83.55 oz-in | 1.3 | 0.37 oz-in² | 0.701 lbs | 4 | Online |

| 4118L-07S | NEMA 17 | 1.670 in | 1.8° | Series | 1.890 in | 1.05 AMP | 83.55 oz-in | 5.2 | 0.37 oz-in² | 0.701 lbs | 4 | Online |

| 4118M-06P | NEMA 17 | 1.670 in | 1.8° | Parallel | 1.580 in | 1.4 AMP | 62.31 oz-in | 2.7 | 0.28 oz-in² | 0.602 lbs | 4 | Online |

| 4118M-06S | NEMA 17 | 1.670 in | 1.8° | Series | 1.580 in | 0.7 AMP | 62.31 oz-in | 10.8 | 0.28 oz-in² | 0.602 lbs | 4 | Online |

| 4118S-04P | NEMA 17 | 1.670 in | 1.8° | Parallel | 1.340 in | 1.34 AMP | 42.48 oz-in | 2.5 | 0.18 oz-in² | 0.401 lbs | 4 | Online |

| 4118S-04S | NEMA 17 | 1.670 in | 1.8° | Series | 1.340 in | 0.67 AMP | 42.48 oz-in | 9.9 | 0.18 oz-in² | 0.401 lbs | 4 | Online |

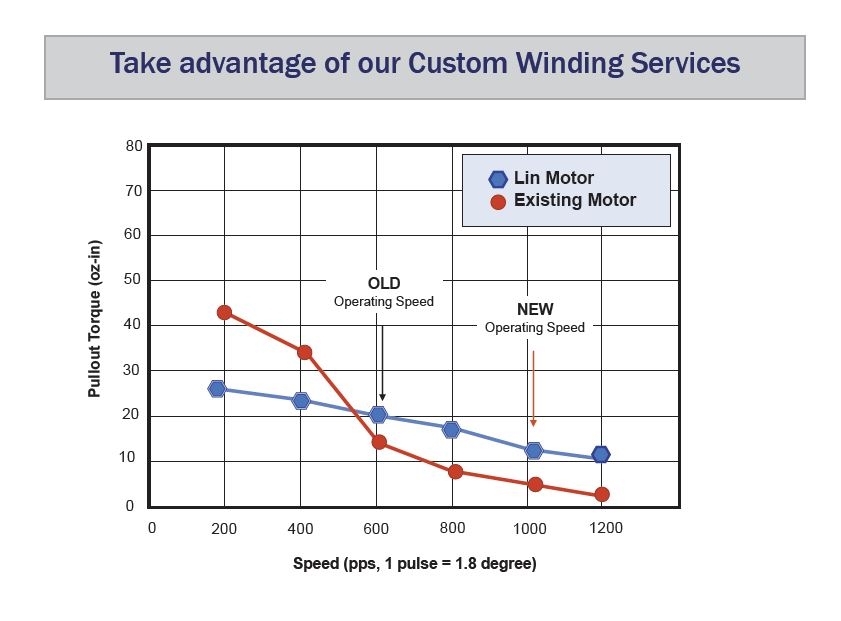

Torque Curves

Speed

- 4118C-01

- 4118L-07P

- 4118L-07S

- 4118M-06P

- 4118M-06S

- 4118S-04P

- 4118S-04S

Find the motor that fits your Target Torque (oz-in) and Target Speed (RPM)

Operating Specifications

| Radial Play | 0.001 in @ 1 lbs |

| End Play | 0.003 in @ 3 lbs |

| Shaft Run Out | 0.002 TIR |

| Concentricity of Mounting Pilot to Shaft | 0.003 TIR |

| Perpendicularity of Mounting Pilot to Face | 0.003 TIR |

| Max Radial Load at Dimension "K" from mounting face | 6 lbs |

| Dimension "K" | 0.620 in |

| Max Axial Load | 6 lbs |

| Maximum Case Temperature | 176.00 °F maximum |

| Ambient Temperature | -4 °F to 122.00 °F |

| Storage Temperature | -4 °F to 212.00 °F |

| Humidity Range (%) | 85% or less, non-condensing |

| Magnet Wire Insulation | Class B 130 deg C |

| Insulation Resistance | 100M Ohm at 500 VDC |

| Dielectric Strength | 500 VDC for 1 min |

Features

Unbeatable Value

The 4118 Series stepper motor is our best-selling stepper motor for numerous reasons: it delivers unbeatable balance between high performance and low price; it offers a high range of customizations; and its wide performance range makes it ideal for many applications.

Versatile performance

The 4118 Series stepper motor is a good fit for wide range of applications. The series is available in many stator lengths, from 1.34” (34mm) to 2.34” (59.4mm). Holding torque ranges from 44 oz-in (0.3 Nm), up to 115 oz-in (0.88 Nm). High range of dynamic torque with speed up to 1200 RPM. And a large selection of windings to meet your specific requirements.

Lin Engineering Quality

Every component and every motor that leaves our facility must meet our mean value control. Additionally, every motor is tested to meet the required electrical specifications (resistance, inductance, leakage), torque specifications (holding and detent torque), mechanical specification (front shaft extension dimension and overall body length), and any other special feature specification. We want to ensure that your motor delivers the precise specifications you require. This gives you confidence that your motors will perform consistently and reliably within your application.

Specialty Motors

Get the motor you need

Just fill out a Request for a Quote form, and tell us about your application and your needs. One of our applications specialists will review your request, and provide you with a quote promptly.