Specialty Motors and Innovative Solutions

Lin Engineering's specialty motors are designed and manufactured to deliver optimized performance and/or to satisfy specific applications

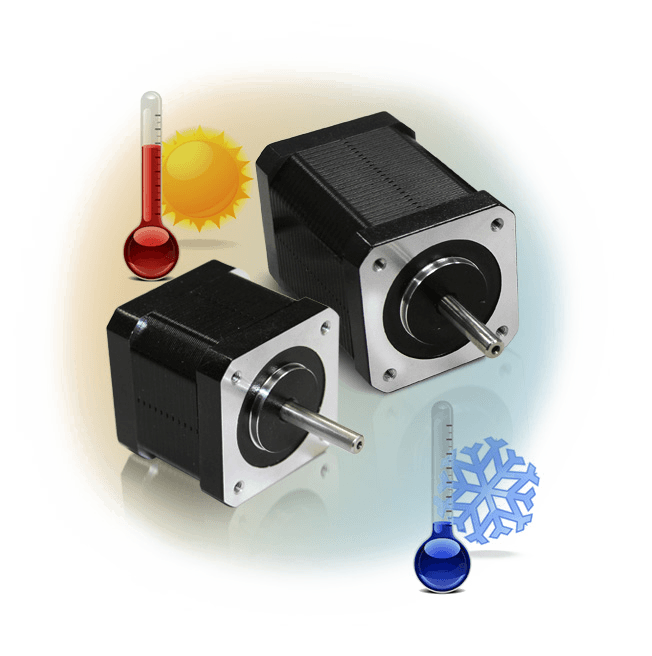

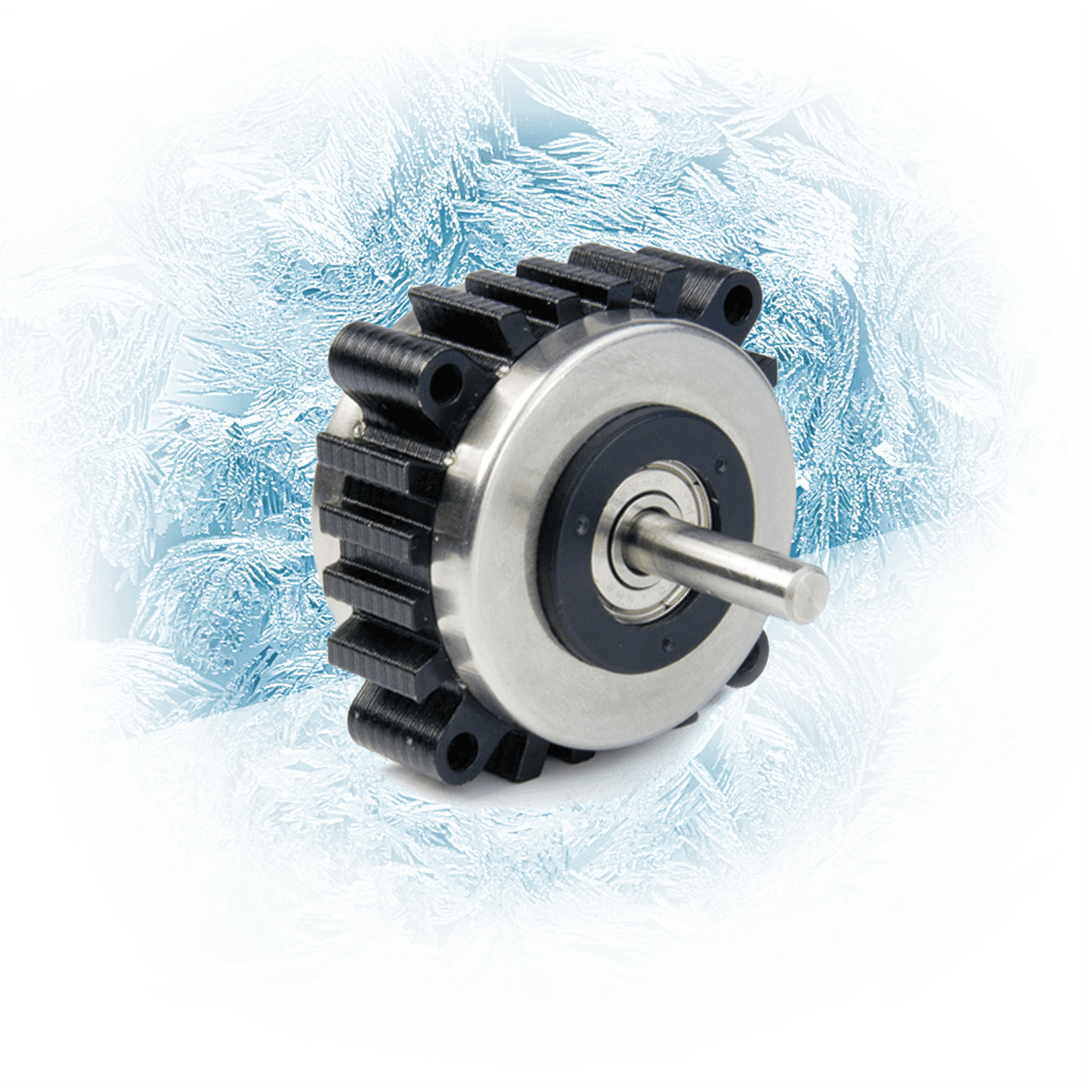

Motors capable of withstanding extreme environments

These motors are designed and manufactured to operate in unique environments for specific applications. Vacuum-rated motors, for example, are necessary for environments where out-gassing needs to be minimized such as vacuum chambers, space applications, and clean room environments. IP (Ingress Protection) rated motors are perfect for applications exposed to humidity, water, oil, and other various debris. We also carry motors that are specifically designed to operate in extreme hot and cold temperatures.

- Vacuum and UHV grade Motors – 10E-7 Torr

- Ingress Protection (IP) Rated Motors – IP67

- Hot/Cold temperature operating Motors – -70°C to 130°C

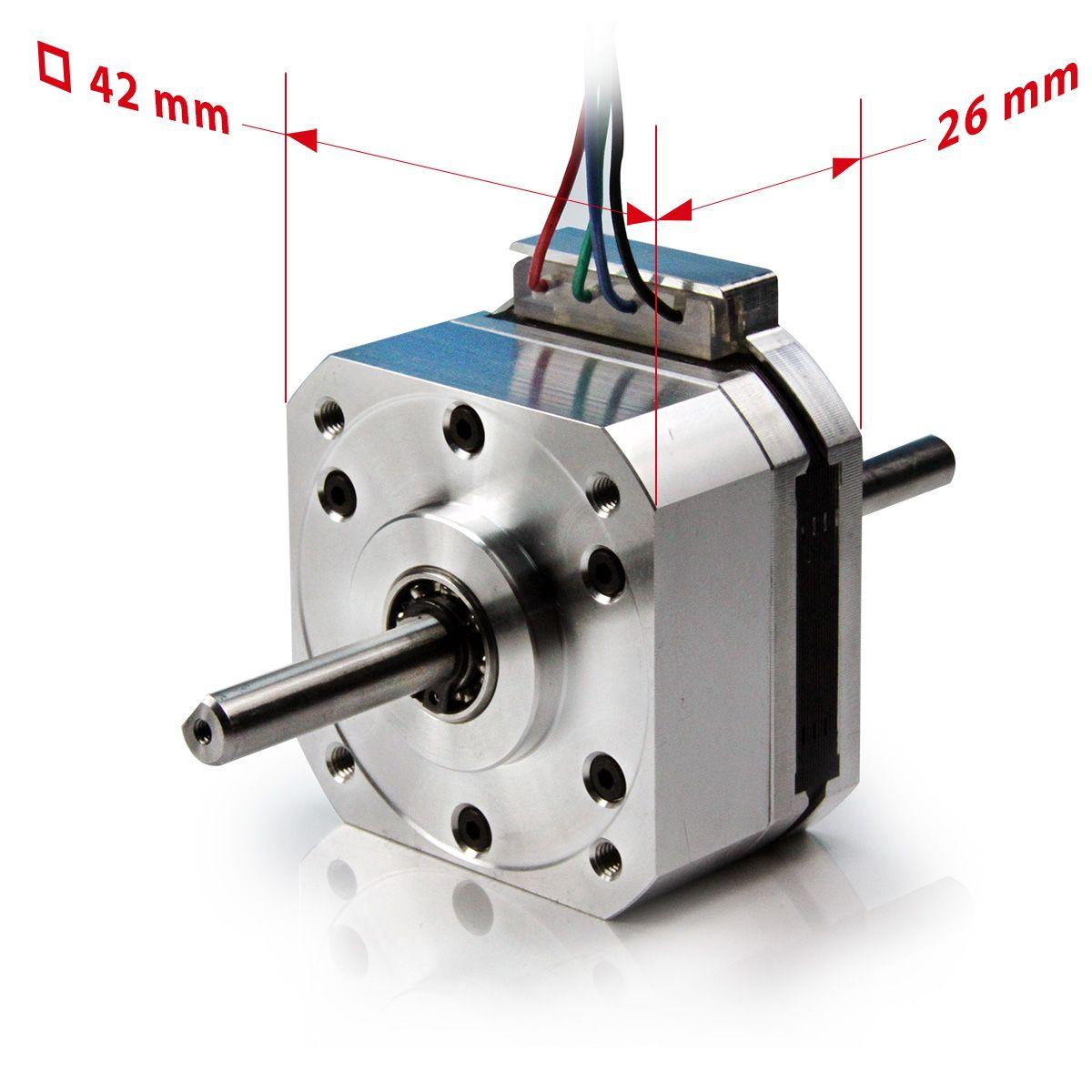

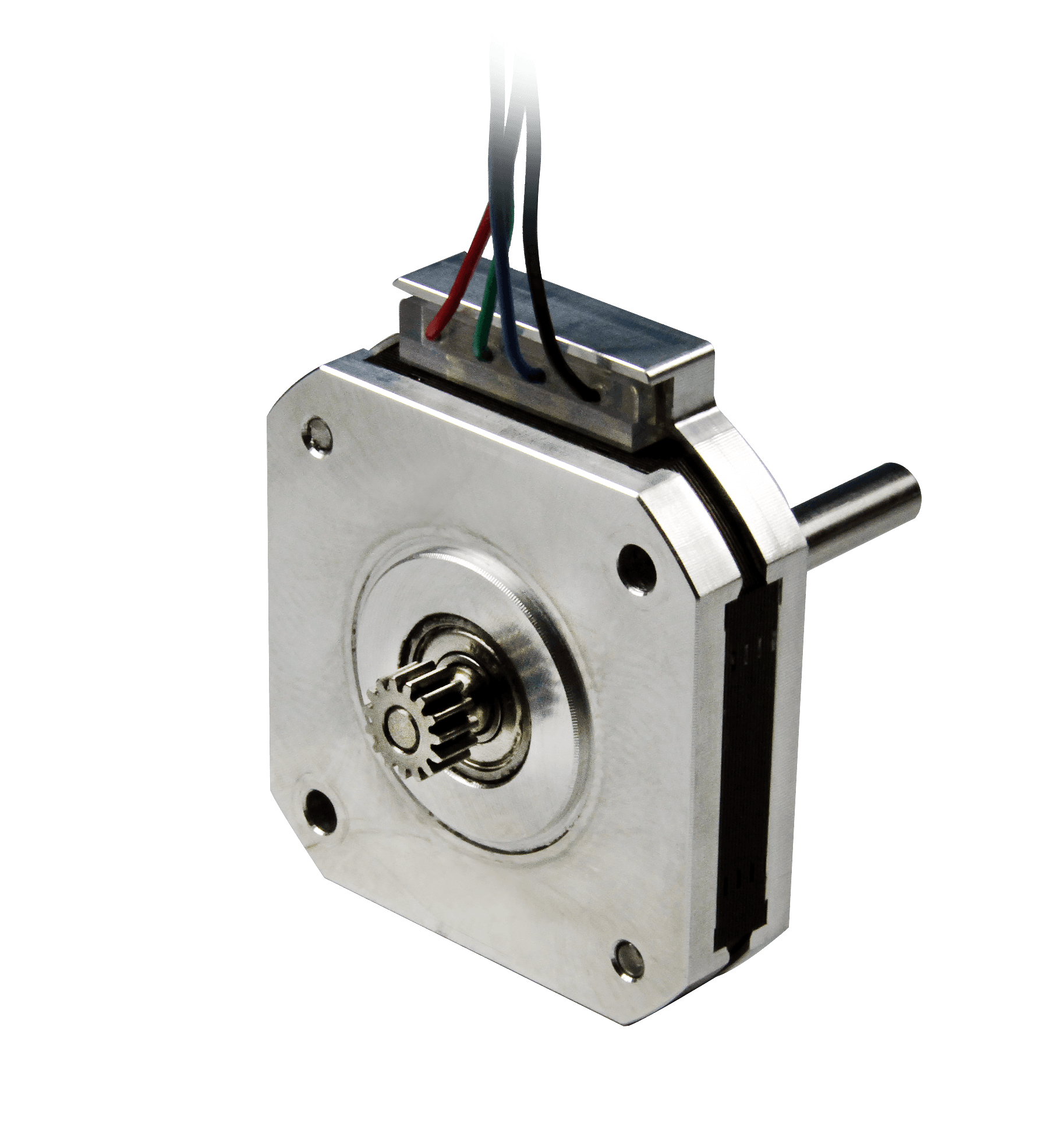

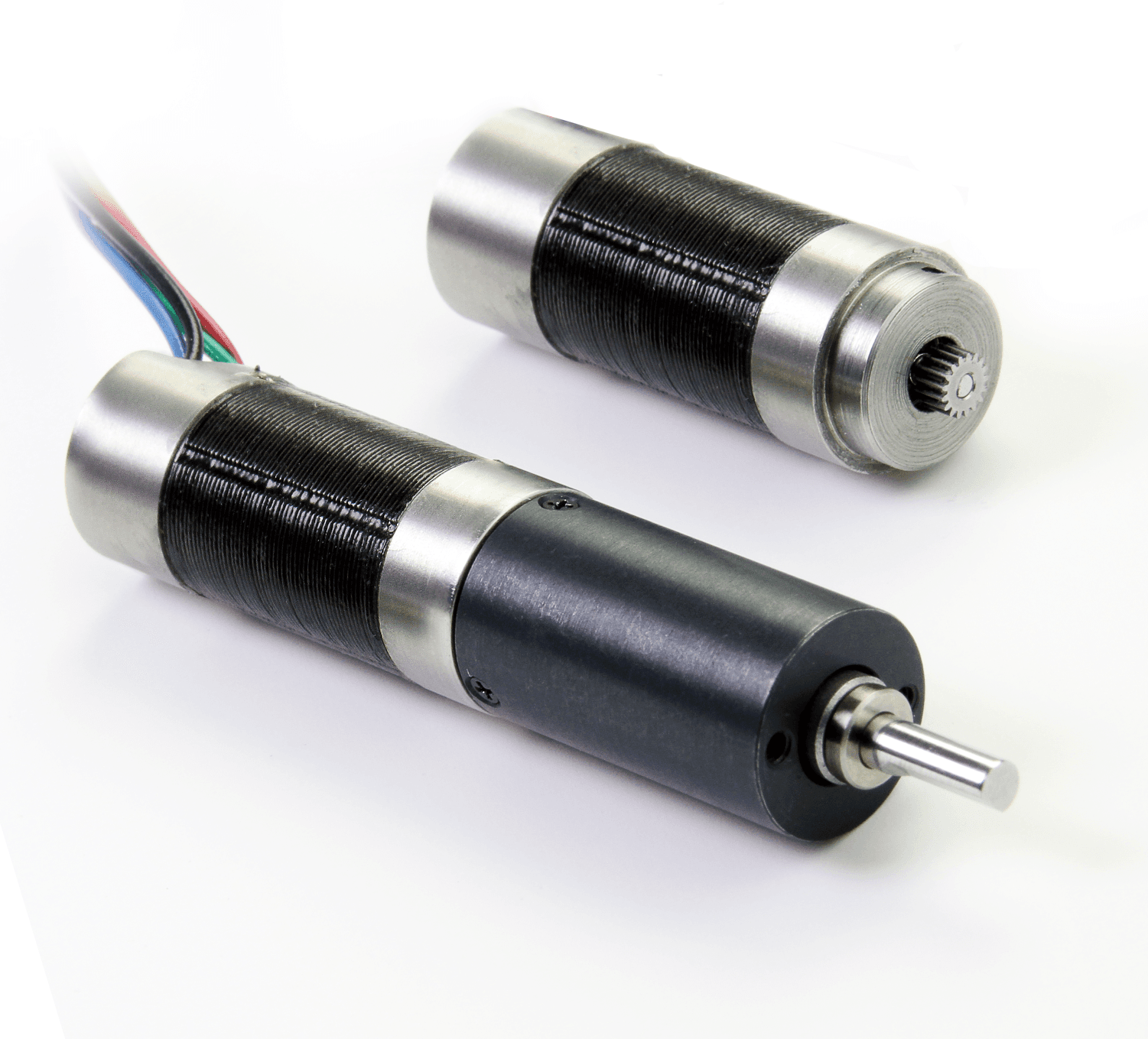

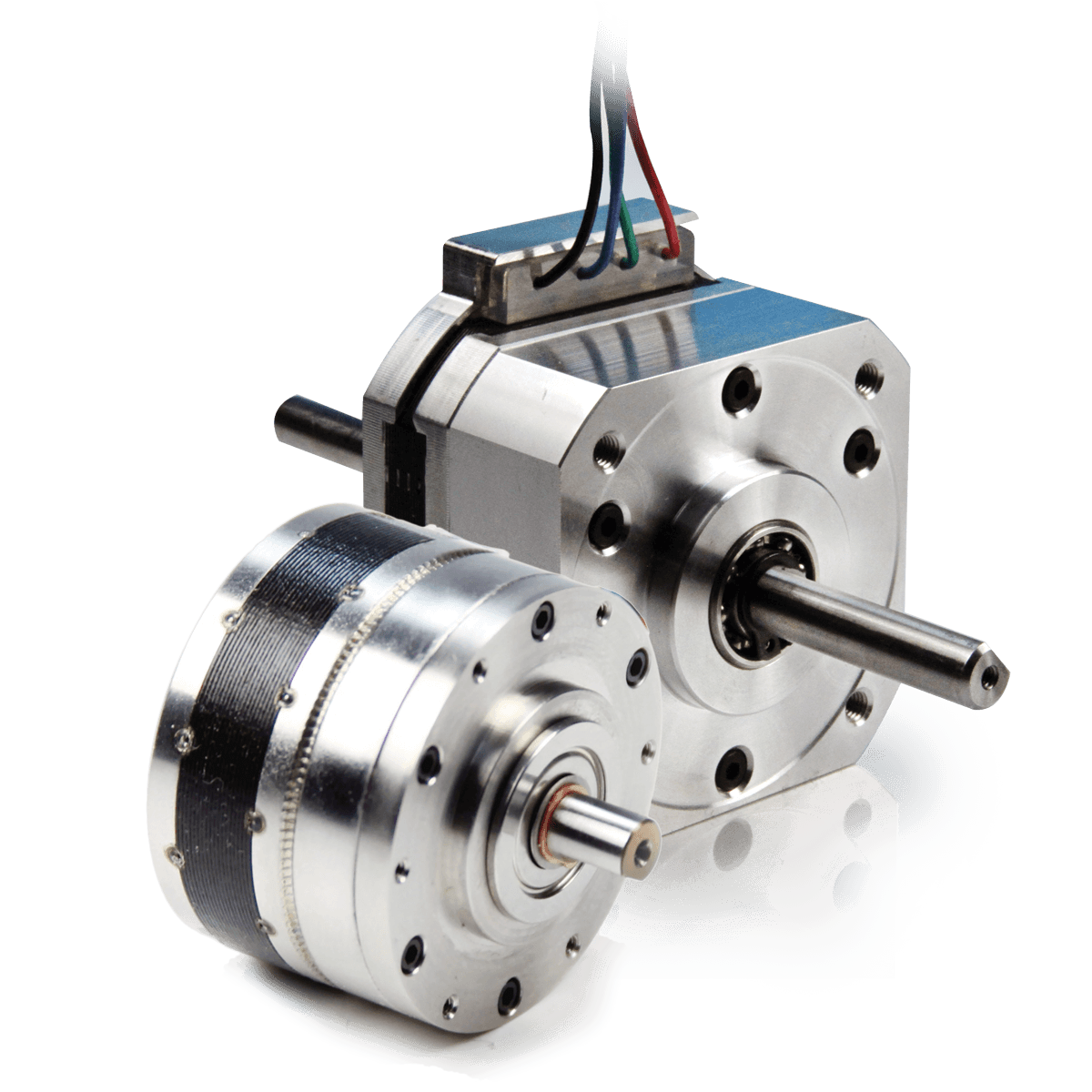

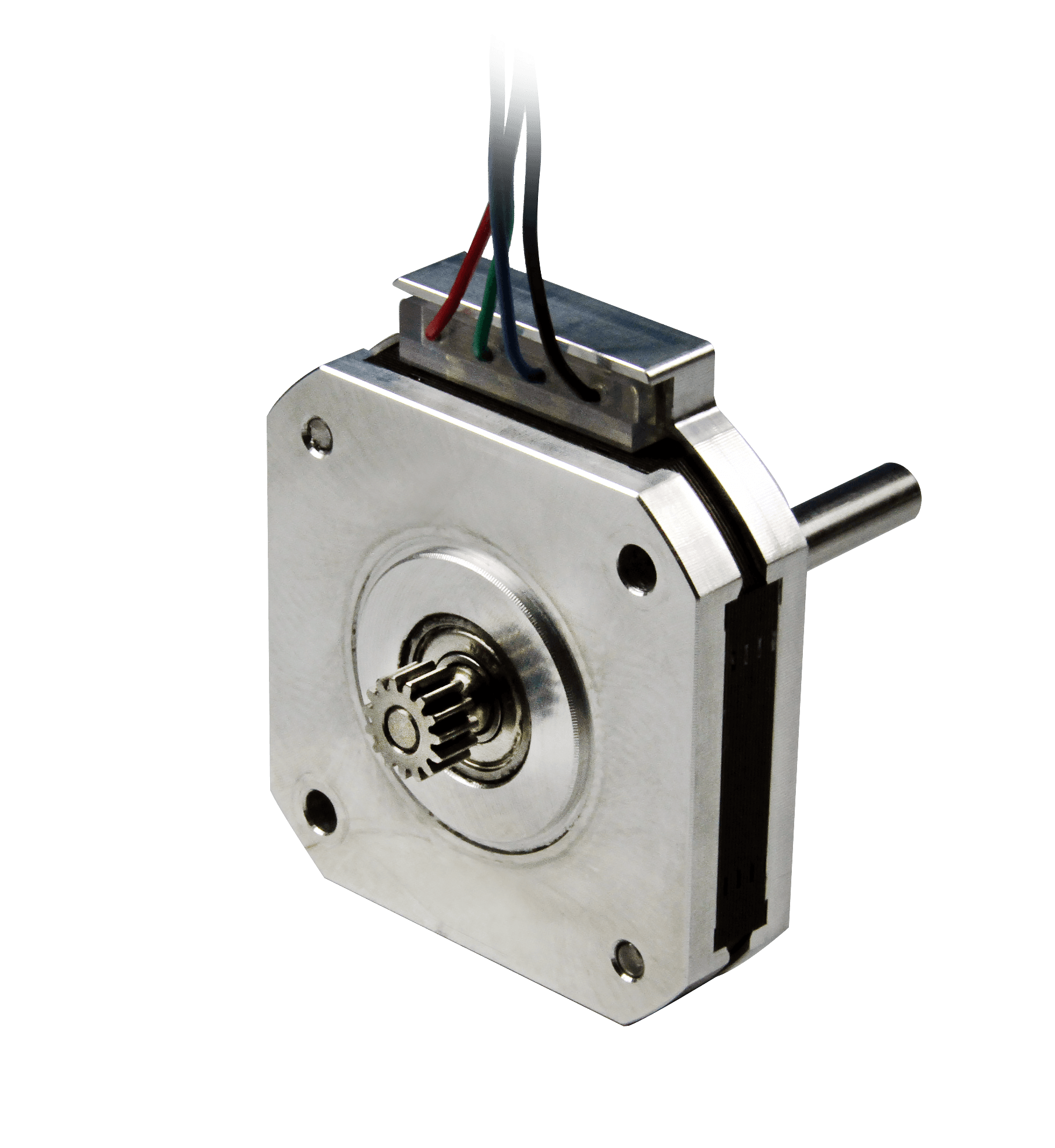

Geartrain Integrated Motors

Motors with an integrated gearbox can reduce length by up to 50% when compared to a conventional motor with a gearbox mounted. This allows smaller and more powerful motors to be used in applications they would traditionally not fit into. The geartrain integrated motors come in a variety of sizes and gear ratios. For example, our integrated geartrain NEMA 17 motor measures just 26 mm (1.02”) in length while providing 0.635 Nm (90 oz-in) of holding torque. As well the geartrain can be customized to provide protection from high or low temperatures by use of special lubrication.

- Ultra slim design with integrated gearbox

- Variety of gear ratios

- Gears can be customized for a wide range of temperatures

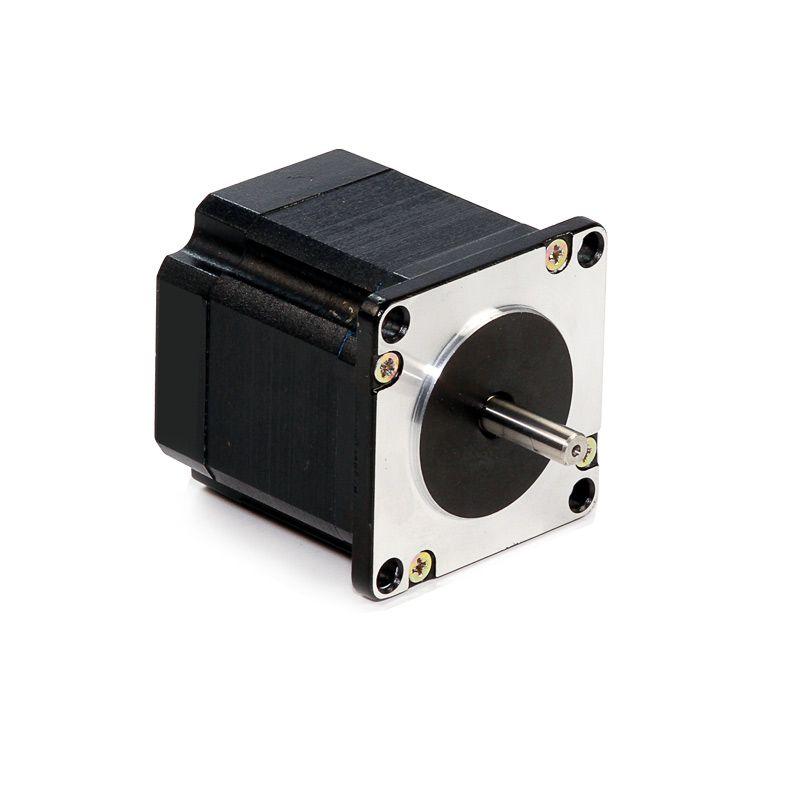

Slim Design Motor Family

In many applications, reducing the overall length of a motor is very key: smaller components normally translate to an overall smaller device which is always a benefit.

Over the years, we have developed a number of different motor options with just that in mind: reducing overall length without sacrificing a lot of performance. Utilizing our unique stator and end-cap design allows us to reduce the length of the motor by up to 50% without sacrificing performance.

These ultra-slim motors are available in a variety of shapes and sizes, utilizing standard NEMA 14 and 17 mounting patterns, as well as custom or proprietary mounting options.

- Ultra slim design

- As thin as 12.5mm (0.49”) in overall length

- Ranging from NEMA 14 (36mm) to NEMA 17 (42mm) mounting options

- High torque density

- Up to 50% shorter than a standard motor with a similar performance range.

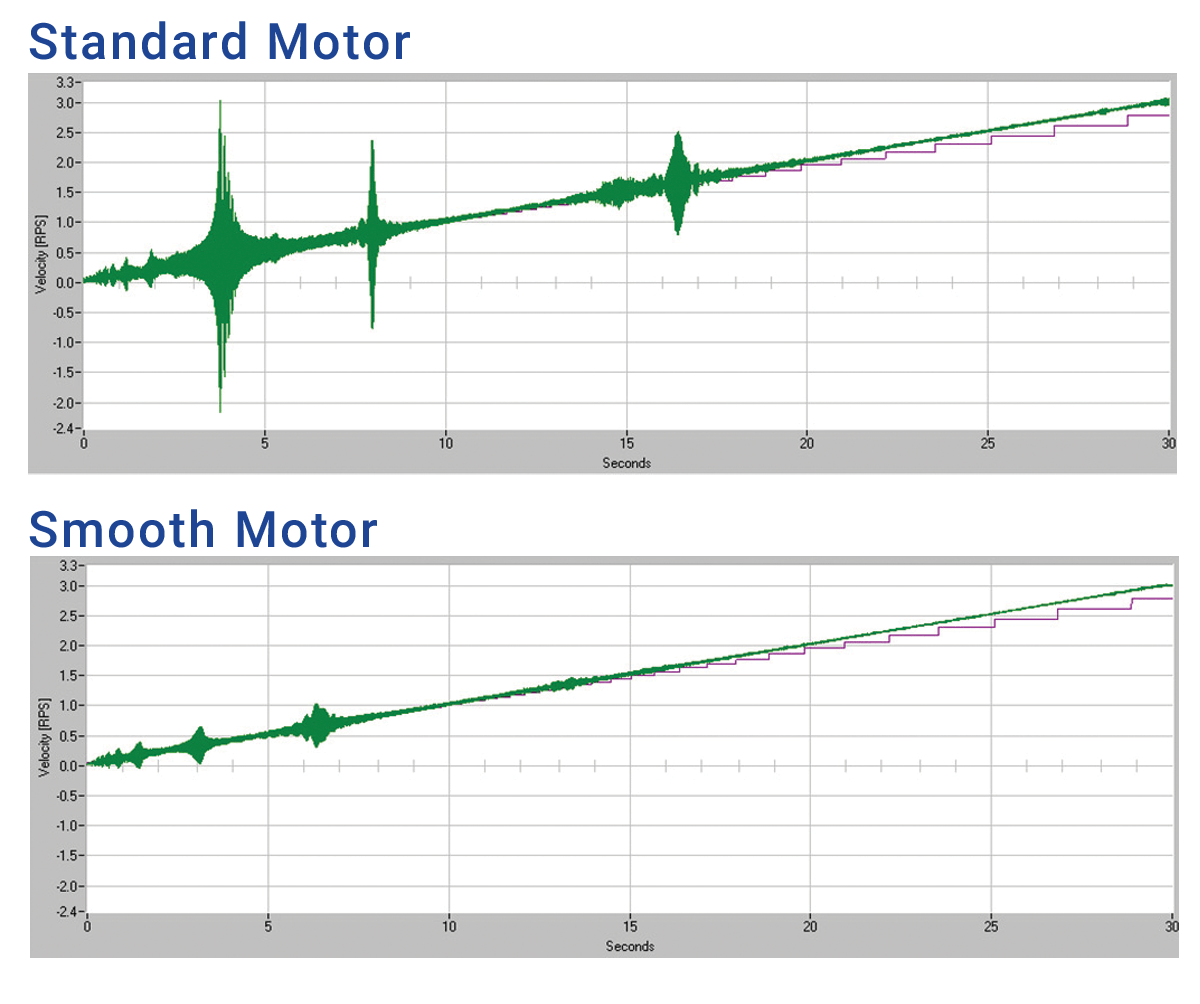

Smooth Movement Spectrum

These motors are designed to deliver smooth and vibration-free movement throughout the performance range of the motor. By utilizing our proprietary stator and rotor design, as well as specific winding recipes, we can reduce unwanted vibration and resonance from the motor to provide the smoothest motion within your application. Reducing detent torque also improves accuracy, smooths operation, and reduces noise. Best of all, modifying the unique flux path design does not change the dynamic torque output.

- Low resonance and overall vibration

- Lower detent torque

- Different sizes and step angles are available

- Quieter operation

Thermally Optimized Design

Our thermally optimized motors are designed to generate less heat than a conventional motor by up to 30% while delivering similar torque output. Thermally optimized motors lower power consumption and lower operating energy costs. Additionally, motors can be safely overdriven to temporarily increase torque output by up to 20%. Thermally optimized motors are ideal for applications that are sensitive to heat generation or require increased operating efficiency.

- Up to 30 percent cooler operation

- Lower power consumption

- Lower operating energy cost

- Over-drivable for up to 20 percent increased torque

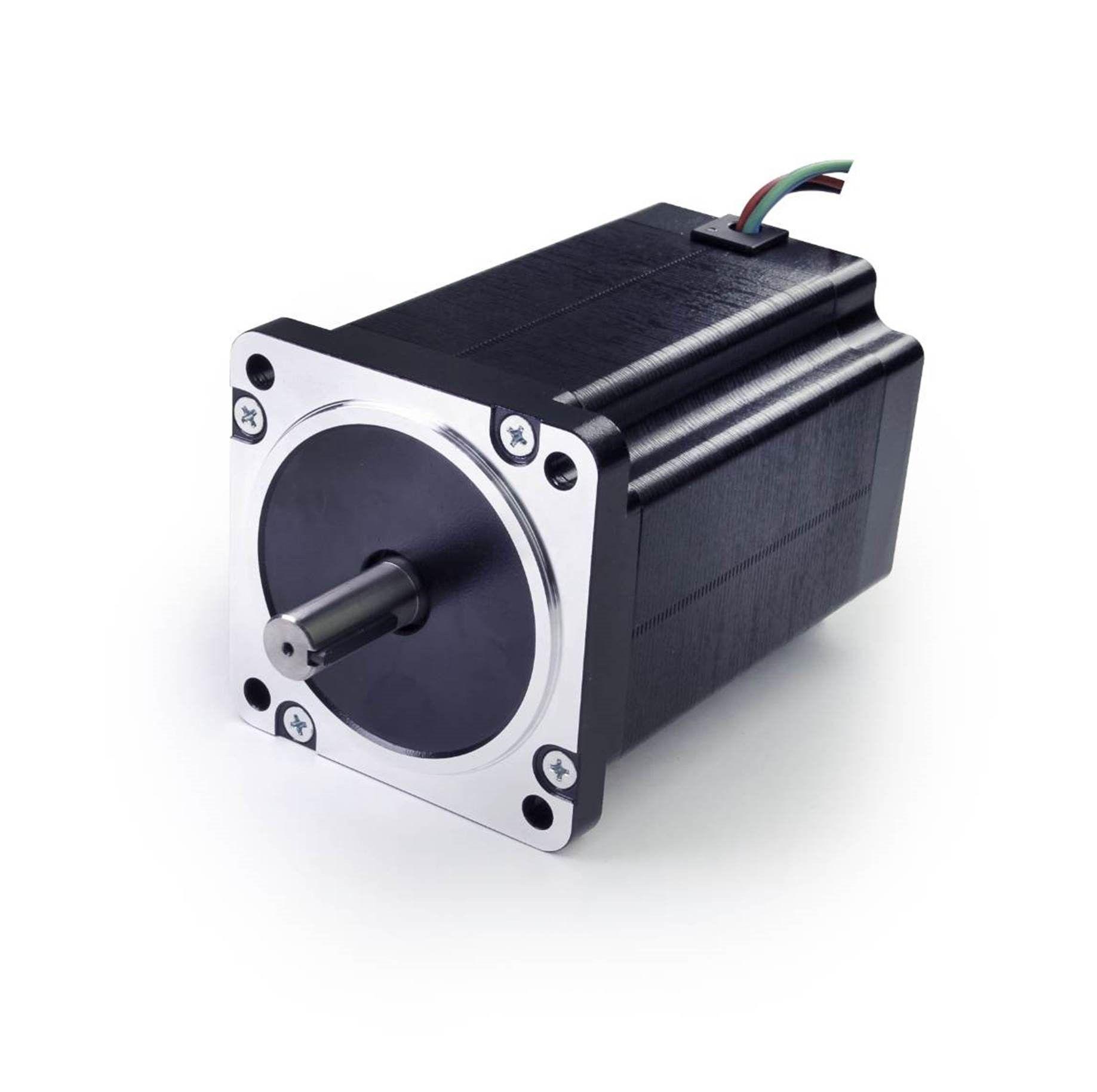

Enhanced Power Density Motors

Lin Engineering patented Enhanced Motor technology provides 40% more torque across the entire speed range of the motor without increasing the drive voltage or current. This is due to our unique motor design providing an exceptional torque-to-size ratio. Additionally, enhanced motors can provide the performance of a standard motor while reducing the power draw, often reducing the cost of driver/electronics; or reducing the frame size of the motor while maintaining performance. Enhanced motors can also run at a higher speed than conventional motors and operate at a lower temperature. Applications using the enhanced motors can use a smaller motor resulting in less heat, weight, and noise.

- Patented Enhanced Motor technology

- 40% more torque without increasing voltage or current

- Achieve higher speed than conventional motor

- Reduce the motor size

- Lower the cost of driver/electronics

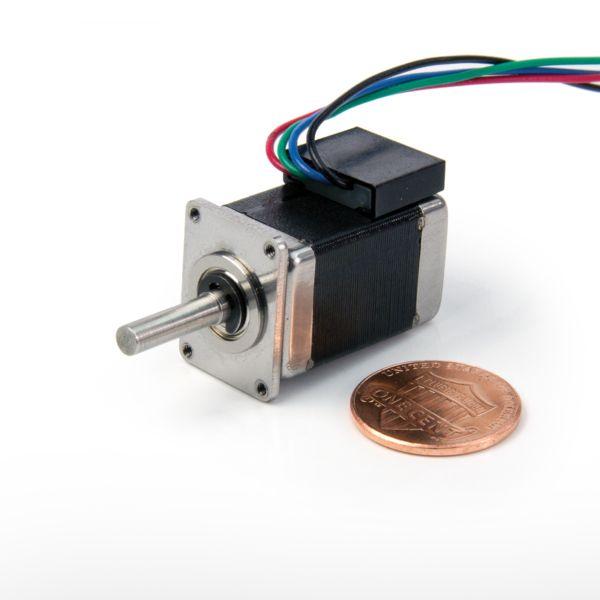

Miniature Size Design in Fractional INCH

One of the biggest problems Engineers face while designing ever-smaller devices is having sufficient power in a smaller package. As the size of equipment decreases, the demand for smaller motors increases. Oftentimes small enough motors simply don’t exist, and if they do, they do not provide enough torque or speed to be useful in the application. Often, the only option is to use a large framed motor and shrink everything else around it.

Lin Engineering solves these problems by designing innovative and capable motors that can maximize performance. Including the most powerful NEMA 6 motor on the market, as well as small motors with our HPM technology.

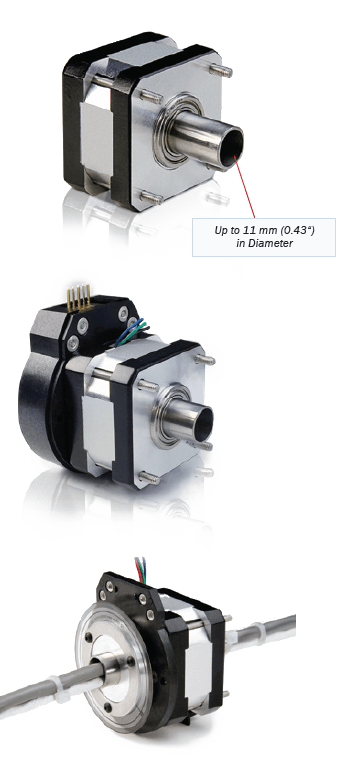

Large Hollow Shaft

Conventional stepper motors cannot accommodate large-diameter shafts without sacrificing torque and performance. Torque is dependent on the size of the magnet placed in the rotor. Therefore, a large diameter shaft reduces the space available for the magnet, thus sacrificing torque. With the unique design of our Z series motors, we can accommodate a large shaft, up to 11mm Inner Diameter, without sacrificing the motor’s torque or performance.

ZH-Series motors benefit from the same performance enhancements as the Z-Series motors. Eliminating the detent torque drastically improves the accuracy, smoothness, and noise emissions.

- Hollow Shaft up to 11mm in diameter

- No torque loss due to the large hollow bore

- Smooth and Quiet Operation

Why Choose Lin Engineering?

Our motors and motion control products are routinely used in medical devices, aerospace components, automation assemblies, and many other applications. Thousands of Engineers from around the world rely on the accuracy, reliability, and consistency of our products as well as our top-notch support.

Speak with one of our motion control experts about your next project.