Stepper Motor Semi Conductor Application Requirements

Stepper Motor Semi Conductor Application Requirements

When selecting a step motor for a machine that is being used in the semiconductor industry, there are many performance trade-offs that need to be considered. Going with a small but accurate step motor will help keep the overall machine smaller, but torque might be an issue. On the other hand selecting a bigger, more powerful motor might not achieve the smooth and high accuracy performance that is demanded by these machines. No matter which motor is used, selecting one that meets the demands of the application is a must.

Although the requirements for step motors vary from application to application, some requirements should be generally considered as a rule of thumb:

- Torque vs. Size

- Cleanliness

- Heat Generation

- High Accuracy

Torque vs. Size

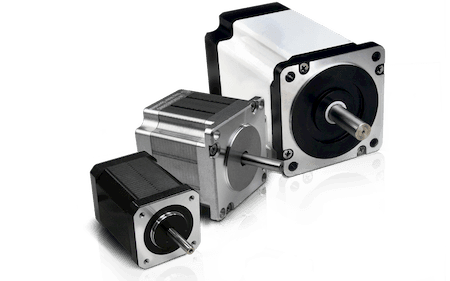

With most semi-conductor applications, it is very important to consider the overall size of the step motor. In general, manufactures adhere to various frame sizes as defined by the National Electric Manufacturers Association (NEMA). The frame size of the step motor can range from the miniature NEMA 8 to the mammoth NEMA 42. Although the frame of each step motor is predetermined by NEMA, the lengths of these motors will vary from manufacturer to manufacturer. Accordingly, the corresponding amount of torque that is produced by these step motors will depend upon the capabilities of each manufacturer. Lin Engineering, for example, manufacturers a NEMA 11 step motor that is available in three different stack lengths:

| MODEL | LENGTH (in) | HOLDING TORQUE (oz-in) |

|---|---|---|

| 211-13 | 1.26 | 9.2 |

| 211-18 | 1.77 | 13.7 |

| 211-20 | 2.01 | 16.6 |

When designing motors for their machines, mechanical engineers have to consider the performance tradeoffs of each motor. Does the extra 7.4 oz-in of holding torque justify moving from a motor that is 1.26” in length to a motor that is 2.01” in length?

Cleanliness

When speaking of the semi-conductor industry, cleanliness is of the utmost importance. In fact, most components that are used in the semiconductor industry are generally rated to function in a cleanroom environment; step motors are no exception.

When using step motors in this industry, it is essential to ensure that the motor is free of all hydrocarbons such as grease and oil. Oil is oftentimes considered the #1 enemy of machines that are being used in this industry because it can easily spread to other components within the machine. The spread of oil can cause components to fail or otherwise heat up and potentially disable the entire machine.

Ensuring that the motor does not emit particles is also a chief concern. Just as is the case with oil and grease, unwanted particles can also spread to other areas of the machine and cause unwanted results.

High Accuracy

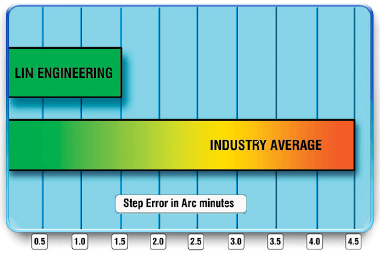

High accuracy is yet another important necessity for motors operating within the semiconductor industry. Step motors rotate in terms of degrees and all of them will have some inherent form of step error. Choosing one with the least amount of error most often leads to successfully integrating the motor to the application.

Step error is measured in miniature increments of arc minutes, where, 1 arc minute equals 1/60°, or 0.0167°. Lin Engineering’s 0.9 degree motors maintain +/- 1.5 arc minute error under 1/64 micro-stepping while the industry standard error range for a 0.9° step motor is +/- 4.5 to +/- 18 arc minutes. What does that mean? Each step that the motor takes is 0.9° divided by 64, or, 0.014°. With every step that’s taken, the maximum error from a Lin Engineering 0.9 degree step motor will be a mere 0.025°.

Heat Generation

Providing any object that is powered through electricity with current will result in some natural heat generation; nothing can be done to stop this. However, it is very important to try and control the amount of heat that is produced as the generated heat has nowhere to dissipate. Hence, it’s no surprise that selecting the most efficient motor is the way to go.

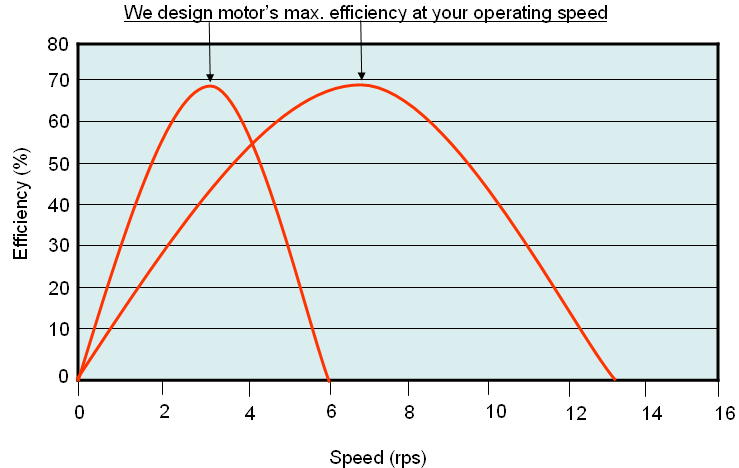

Step motor manufacturers can help achieve this goal through the creation of new motor windings. Every step motor has a maximum efficiency point. With more or less windings and different wire gauges, Lin Engineering can design the motor to be most efficient at the desired operating speed. Power will go towards output torque rather than heat generation coming out of the motor itself.

The curve below depicts how we can manipulate the efficiency curve per the requested speed specification. Imagine using a step motor at very slow speeds, but the efficiency is either of the two curves shown below. Excess heat would be generated due to such inefficiency.

In addition to selecting the right motor to maximize efficiency, there are ways to select a lower resistance winding to minimize the overall I2 R heat.

News

Continue Reading

Stepper Motor Medical Application Requirements

When selecting a step motor for an application in the medical industry, many factors need to be considered. Although the requirements for step motors vary from application to application, some requirements should be generally considered as a rule of thumb. This article will help walk you through some of those requirements and how Lin Engineering can help.

What is R-Winding and How Does it Affect My Stepper Motor?

Most step motor users are familiar with Series and Parallel connections; now, the patented R-Winding (U.S. Patent No. 6,969,930) has been created to reduce noise and vibration for lower-torque applications.