What is R-Winding and How Does it Affect My Stepper Motor?

What is R-Winding and How Does it Affect My Stepper Motor?

Most step motor users are familiar with Series and Parallel connections; now, the patented R-Winding (U.S. Patent No. 6,969,930) has been created to reduce noise and vibration for lower-torque applications.

Step motors typically run with a driver that either half steps or full steps. For example, for a 1.8° stepper, one step will be 1.8° if set to full stepping or it will be 0.9° if it is set to half stepping. Looking closer at the electrical phase changes during half stepping, a typical sequence is to turn on or give full current to, the A phase. Next, both A and B phases will be turned on, then A will turn off and only B will turn on, and so on. When only 1 phase is energized, we define this as the 1-Phase ON position. The chart below shows the sequencing process to make a motor turn.

| STEP NUMBER | PHASE A | PHASE B | DESCRIPTION | PHASE ANGLE |

|---|---|---|---|---|

| 1 | ON | OFF | 1-Phase ON | 0° |

| 2 | ON | ON | 2-Phase ON | 45° |

| 3 | OFF | ON | 1-Phase ON | 90° |

| 4 | ON | ON | 2-Phase ON | 135° |

| 5 | ON | OFF | 1-Phase ON | 180° |

| 6 | ON | ON | 2-Phase ON | 225° |

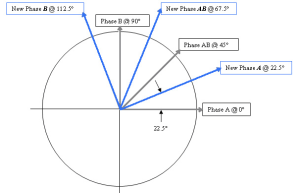

If we were to depict the two Phases, A and B, in a vector diagram to demonstrate the relationship between the two electrical phases, the phase angles for each step is in increments of 45°: 0°, 45° 90°, 135°, 180°, 225°, 270°, 315° and back to 0°. At the 45° marker, this vector shows that both A and B phases are on because it is sitting in the first quadrant of the electrical phase diagram. When the vector shifts to 90°, it shows that the B phase is still on, and now A is off.

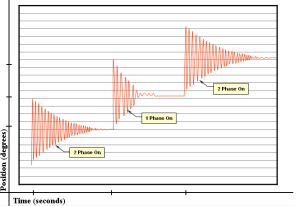

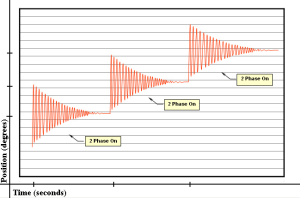

The settling time characteristics of the motor are different at 1-phase ON and 2-phase ON positions. The step time profile from every driver/controller assumes that the settling time character of each step is the same. Thus, erratic motion occurs when the step time is not synchronous with the rotor position. A traditional step response is shown in figure 1 graph.

The R-winding was created to eliminate the 1-phase ON position and to minimize the differences in the magnetic field over the entire range of the phase angles. With the new R-winding, the rotor position will be at 2-phase ON at all times during half-stepping. This can be made possible by not always applying 100% current into one phase only. Current is more evenly split between A and B phase. The new phase angles for each position will be 22.5°, 67.5°, 112.5°, 157.5°, 202.5°, 247.5°, 292.5°, 337.5° and back to 22.5. Thus, the settling time character of each step is now identical.

If resonance or erratic motion occurs from step to step, corrective actions are to increase microstepping in order to decrease the oscillation of each step. But torque will decrease with microstepping. With the R-winding, users can eliminate resonance yet still remain the same output torque performance at half-stepping. Notice in the R-winding step response, each step is made with an even amount of step time profile.

News

Continue Reading

Stepper Motor Semi Conductor Application Requirements

When selecting a step motor for a machine that is being used in the semi-conductor industry, there are many performance tradeoffs that need to be considered. Going with a small but accurate step motor will help keep the overall machine smaller, but torque might be an issue. On the other hand selecting a bigger, more powerful motor might not achieve the smooth and high accuracy performance that is demanded by these machines. No matter which motor is used, selecting one that meets the demands of the application is a must.

Design Accuracy Comparison 0.9° vs. 1.8° Stepper Motors

Often times, when an engineer is selecting a step motor for his or her application, one important decision that needs to be made, is whether or not to choose a 0.9° or a 1.8° step motor. When making a decision of this magnitude, two factors will invariably come into play: performance and price. With the ever-increasing role of competition in today’s motion control industry, both performance and price are major difference makers in every decision.