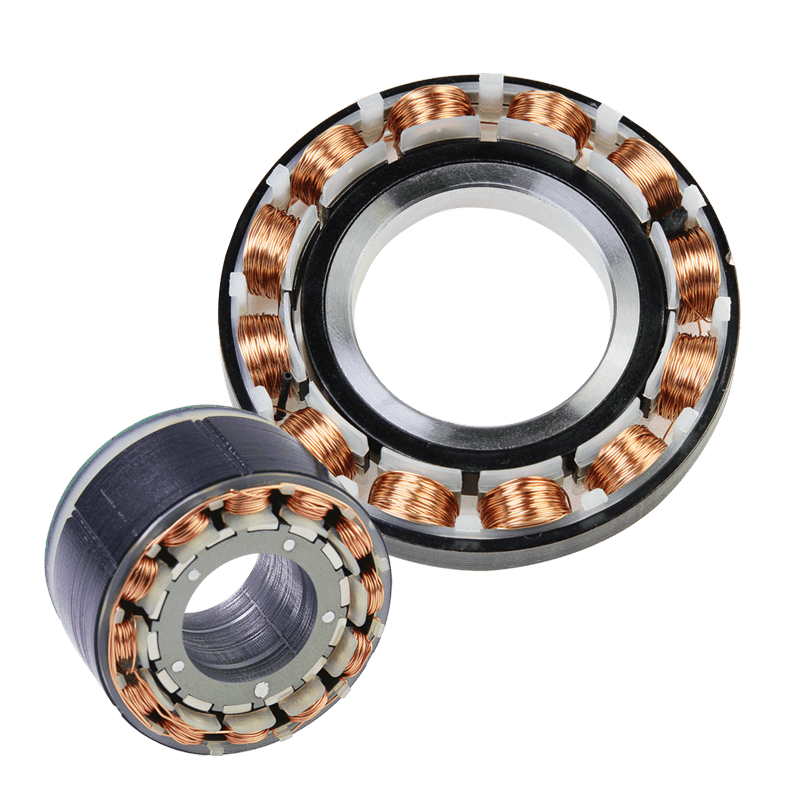

Motors Optimized for

Humanoid Robot Actuation

TORQUE DENSE + COMPACT DESIGN + THERMALLY EFFICIENT

Motors that pack high Km into a compact, thermally efficient design, delivering maximum torque density while maintaining cool 85° C temp.

U.S.-BASED, SCALABLE MANUFACTURING WITH RELIABLE SUPPLY CHAIN

Fast California prototyping, scalable production, and a vertically integrated global supply chain.

CUSTOMIZED AND OPTIMIZED FOR THE REAL WORLD DUTY CYCLES

Motors optimized to deliver maximum efficiency across variable load cycles without overheating.

Need a Custom Motor Solution?

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.

- Size range: 40 mm to 160 mm outer diameter

- Torque output: up to 30 Nm peak torque

- High Motor Constant (Km): delivers more torque per watt for cooler, more efficient operation

- Compact integration: frameless design mounts directly into your actuator for maximum space savings

- Robotics ready: optimized for precision, durability, and smooth performance in human-centric applications

- Available in direct drive or strain wave geared configurations

- Compact housed motors with high torque density and smooth motion

- Low cogging and minimal torque ripple for precise motion control

- Optimized thermal design

- Customizable windings, shafts, and options to fit your application

- Cog-free operation for smooth motion at both low and high speeds.

- Compact, lightweight design with reduced rotor inertia for faster acceleration.

- High torque and efficiency enabled by patented winding structure.

- Low noise and vibration, ideal for precision and sensitive applications.

- Energy-saving performance with minimal iron losses and high control sensitivity.

Customized Motor Solutions

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.

High Km in Compact Form Factor

Our PowerCore frameless motors outperform the competition.

- Up to 20% higher Km / power density for superior torque output

- More torque with same frame size or reduce length/mass by up to 15%

- Runs cooler — up to 20% lower touch temperature

- Reduced current draw by as much as 15%

- Extended actuator life up to 400% and improved battery efficiency

Thermal Efficiency & Continuous Duty Performance

Our frameless motors are engineered with a high Km constant and optimized windings to minimize I²R (copper) losses to maintain 85 °C winding temperature envelope. The motor delivers high continuous torque while preventing excessive heat transfer to sensitive components such as encoders, sensors, and gearboxes. Lower motor temperatures reduce or even eliminate the need for external heatsinks, decreasing actuator mass and enabling more compact designs. The result: reliable, predictable performance under demanding duty cycles — exactly what humanoid robots require for reliable motion and long service life.

Customization for Actuator Integration

Our frameless BLDC motors are not one-size-fits-all. We tailor diameters, stack lengths, winding configurations, and interconnect options to precisely match your target torque–speed curve, back EMF profile, and thermal envelope. This ensures the motor isn’t just a component, but a seamless part of your actuator system.

We work side-by-side with your engineering team through co-design, testing, and validation to optimize integration. From inertia matching to thermal management, every parameter is tuned to help you hit performance targets and production timelines with confidence.

Supply Chain Reliability & Scalability

Lin Engineering combines U.S.-based manufacturing with the resources of a global, vertically integrated partner. This ensures a stable supply chain, consistent quality, and compliance with the most demanding industry standards.

From 10 prototype motors to 10 million units in full production, our manufacturing systems are built to scale with your program. In medical devices, laboratory automation, aerospace, and next-generation robotics, we deliver the same commitment: on-time supply, predictable quality, and long-term reliability.

Fast Prototyping, Local Support

Speed to market demands rapid iteration and real-time problem solving. With our Northern California prototyping and manufacturing facility, you can move from concept to hardware quickly and validate designs under real-world conditions.

Our USA-based engineering and applications team partners directly with your developers to refine performance, solve integration challenges, and accelerate the transition from prototype to production — reducing risk while keeping your program on schedule.

Proven Reliability in Robotics

For more than 30 years, Lin Engineering has supplied motors at the core of robotic systems worldwide. Our experience spans collaborative robots, laboratory automation, service robotics, and humanoid platforms — applications where safety, compliance, and smooth interaction with humans are critical.

Our designs address the challenges that matter most in robotics: minimal torque ripple for smooth motion, thermal stability for continuous duty, and long-life durability under repetitive cycles. Engineers rely on our motors because they deliver consistent performance in real-world conditions, not just on the spec sheet.

Work With Us On Your Next Humanoid Project

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.