DriveCore Motor Platform

Engineering Versatility at the Core

DriveCore bridges that gap between the performance of our frameless motors and convenience of a fully housed motor — delivering ready-to-use housed motors and actuators, while still keeping the modular flexibility engineers expect.

Whether you’re prototyping or scaling into production, DriveCore lets you:

- Accelerate development with drop-in-ready designs.

- Customize without compromise: shafts, gearboxes, encoders, brakes, and mounting patterns are all configurable.

- Rely on proven cores built on Lin’s high-Km frameless motor technology for unmatched torque density and efficiency.

Customized Motor Solutions

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.

DriveCore Product Family

DriveCore is a new line of compact, housed motor solutions built on Lin Engineering’s high-performance frameless technology. Available in direct drive or with integrated strain wave gearing, DriveCore simplifies integration, accelerates prototyping, and scales seamlessly from low volumes to mass production.

Direct-drive performance, simplified integration.

- Available in solid shaft or thru-bore hollow shaft configurations.

- Compact form factor for space-constrained systems.

- Ideal for robotics, medical, aerospace, and automation platforms where precision and smooth motion matter most.

- Optional encoders and brakes available for complete joint solutions.

| Part Number | DPC-T085CH026-48A (Straight shaft) | DPC-T085CH026-48A-01 (Hollow shaft) |

| Frame Size | 97.7 mm | 97.7 mm |

| Bus Voltage (Vbus) | 48 VDC | 48 VDC |

| Rated Torque (Trtd) | 3.13 Nm | 3.13 Nm |

| Peak Torque (Tpk) | 8.63 Nm | 8.63 Nm |

| Max Cont. Current (Icont) | 5.23 Arms | 5.23 Arms |

| Peak Current (Ipk) | 14.35 Arms | 14.35 Arms |

| Rated Output Speed (Nrtd) | 606 RPM | 606 RPM |

| View Product Data | View Product Data |

High torque, zero backlash.

- Motor + integrated strain wave gearbox in a single housing.

- Provides precise, compact, zero-backlash motion for robotic joints and humanoid platforms.

- Optional encoders and brakes available for complete joint solutions.

| Part Number | DPC-T085CN008-48A-SA-80 |

| Frame Size | 94 mm |

| Gear Ratio | 80:1 |

| Bus Voltage (Vbus) | 48 VDC |

| Rated Torque (Trtd) | 24 Nm |

| Peak Torque (Tpk) | 51 Nm |

| Max Cont. Current (Icont) | 5.2 Arms |

| Peak Current (Ipk) | 13.29 Arms |

| Rated Output Speed (Nrtd) | 44 RPM |

| View Product Data |

Work With Us On Your Next Project

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.

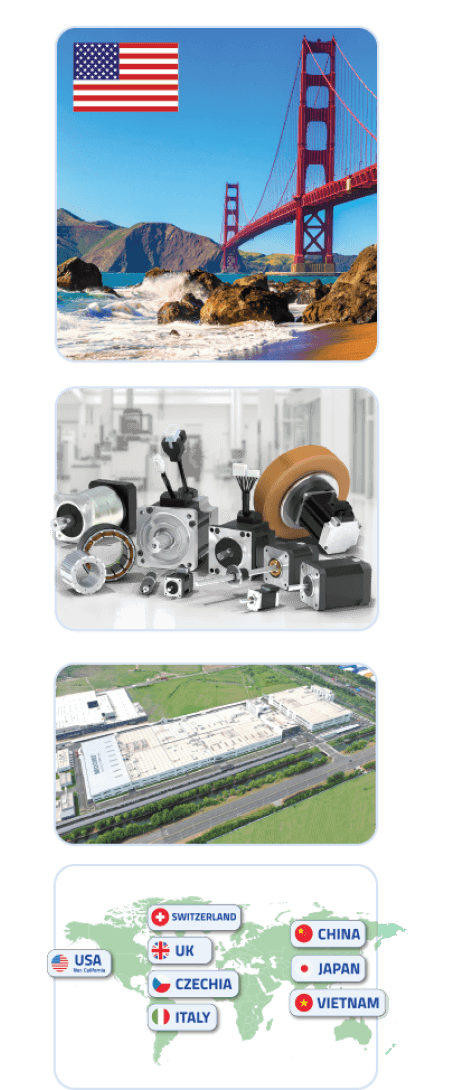

Why Choose Lin Engineering?

For over 30 years, Lin Engineering has supplied motors for robotics, aerospace, medical, and automation systems where performance and reliability are critical. Built under our 4.5 Sigma quality process and backed by U.S.-based prototyping with scalable global manufacturing, we deliver predictable lead times, long-term durability, and seamless integration — from 10 units to 10 million.

- USA-based Engineering and Manufacturing

- Based in Northern California, with engineering and manufacturing on-site

- Fast-track Prototyping

- Off-the-shelf motors and fast prototype turnaround

- Collaborative Engineering Support

- We can work closely with your team to create a customized solution for your specific application

- Engineered for Manufacturability

- Customized, plug-and-play motor solutions

- Sustainable Supply Chain

- Long-term motor manufacturing support throughout the lifecycle of your product

- Scalable Production

- From 10 motors to 10 million motors

- Global Footprint

- Additional manufacturing facilities in Europe and Asia. 1.5 Million sqft of manufacturing space across 8 facilities

- Vertically Integrated

- We manufacture our own components, ensuring supply chain stability and on-time delivery