Lin Engineering's Zero-Tech encompasses a range of advanced motion control technologies designed to overcome common engineering challenges in DC motors. This includes minimizing excessive detent torque for smoother operation, eliminating backlash for precise position control, reducing cogging for uniform motion, compacting motor length to fit into smaller spaces, and enhancing durability against harsh environmental conditions. Zero-Tech aims to deliver superior performance and reliability, meeting the rigorous demands of modern engineering applications.

Zero-Tech

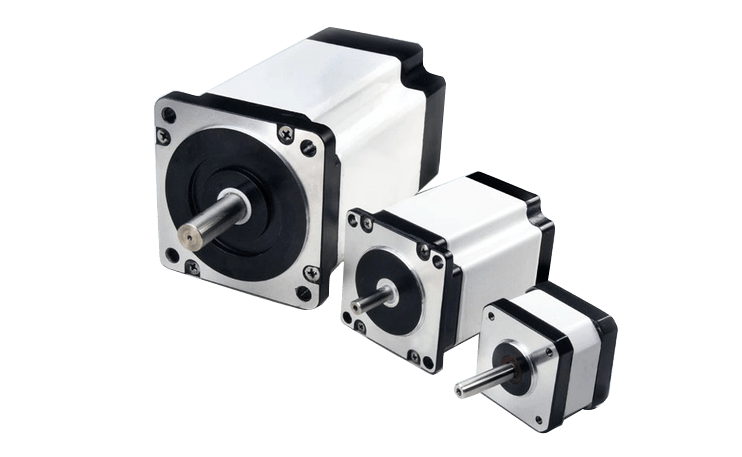

Zero Detent Torque

Lin Engineering's Z series motors, specifically the ZH417 and ZN417 models, are engineered to deliver virtually zero detent torque, resulting in exceptionally smooth motion and enhanced precision and accuracy in operation. These motors are distinguished by their superior performance, maintaining an accuracy of ±1.5 arc minutes under 64x microstepping. This level of precision is significantly higher than the industry standard for 0.9° step motors, which typically exhibit an error range of ±4.5 to ±18 arc minutes. This makes the Z series an ideal choice for applications demanding high accuracy and minimal mechanical resistance.

Zero-Tech

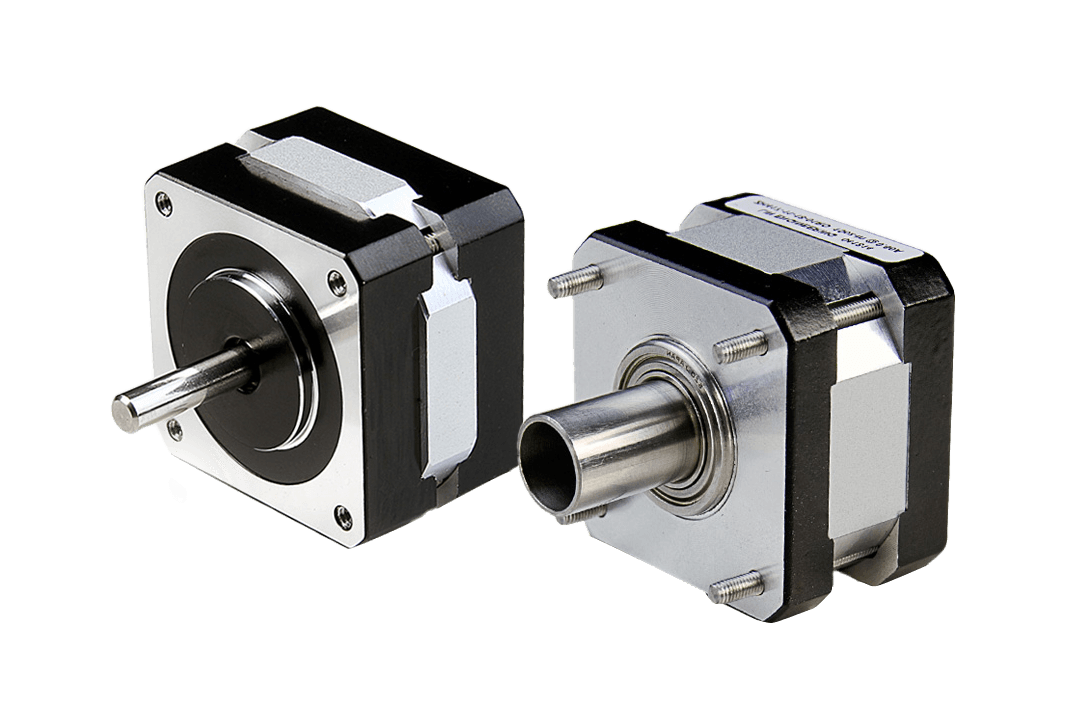

Zero Backlash

Lin Engineering's Zero Backlash technology incorporates the LinFinity Plus anti-backlash nuts into our linear actuators, providing a suite of advanced features that enhance performance across various applications. This technology maintains precision and consistency in movement by eliminating axial and radial play. Additionally, the lubrication reservoir feature reduces the need for maintenance by self-lubricating, while the increased thrust capability allows for handling higher loads. The adjustable preload offers customizable performance to match specific application needs, by reducing drag torque and enhancing efficiency during operation. Together, these features make Zero Backlash technology an optimal solution for applications requiring high precision and reliability.

Zero-Tech

Zero Cogging

Lin Engineering's slotless BLDC motors are engineered to eliminate virtually all cogging torque, enhancing their operational characteristics in precision-dependent applications. The absence of cogging facilitates smoother motion profiles and increases positional accuracy, critical for applications requiring fine control. These motors demonstrate improved efficiency by reducing energy losses typically incurred through magnetic detent forces. Additionally, the lower noise and vibration levels contribute to a more stable system environment and decrease wear on mechanical components, thereby extending the operational lifespan of the motor. This suite of features positions Lin Engineering's slotless BLDC motors as a superior choice for systems where reliability and precision are paramount.

Zero-Tech

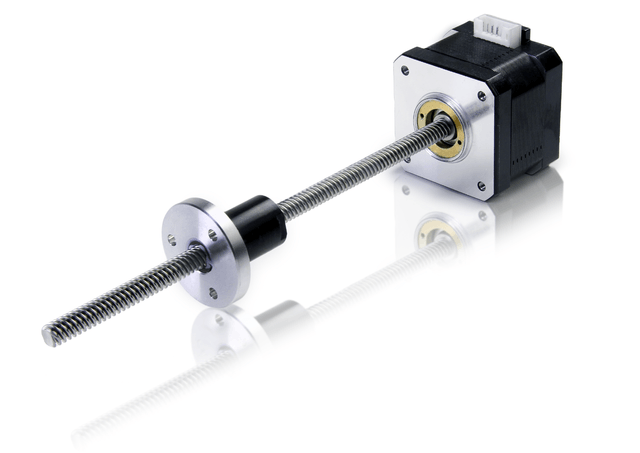

Zero Length

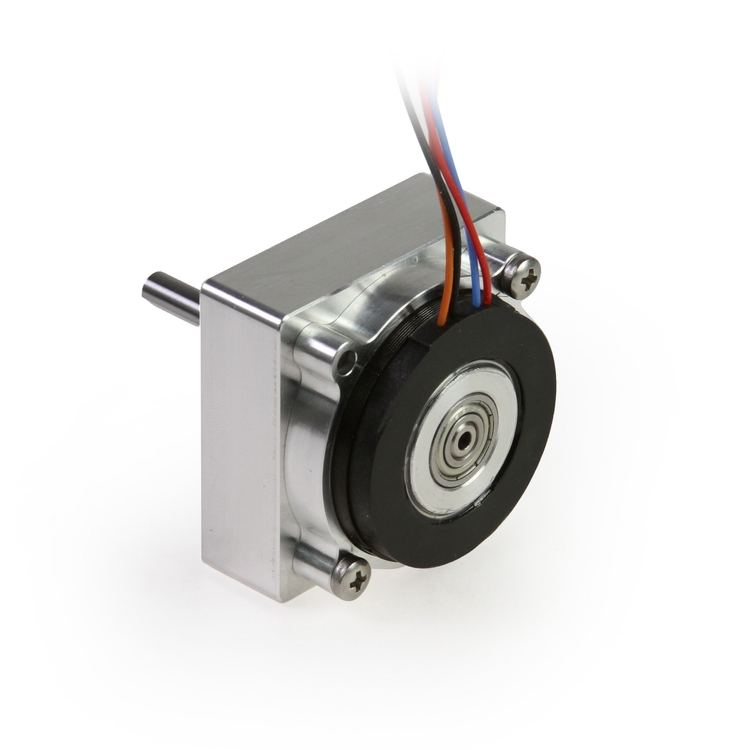

"Zero Length" technology from Lin Engineering optimizes performance by reducing the physical length of our products, exemplified by the new 3618 Series motor. This motor marks a significant advancement in design, integrating high-speed capabilities within a low-profile configuration by eliminating the dead space commonly found between motor and gearbox. When coupled with our slim planetary gearbox, the 3618 Series motor delivers substantial torque over a wide speed range, yet maintains an ultra-slim profile. This design innovation enables enhanced functionality in applications where space constraints are critical, without compromising on power or efficiency.

Zero-Tech

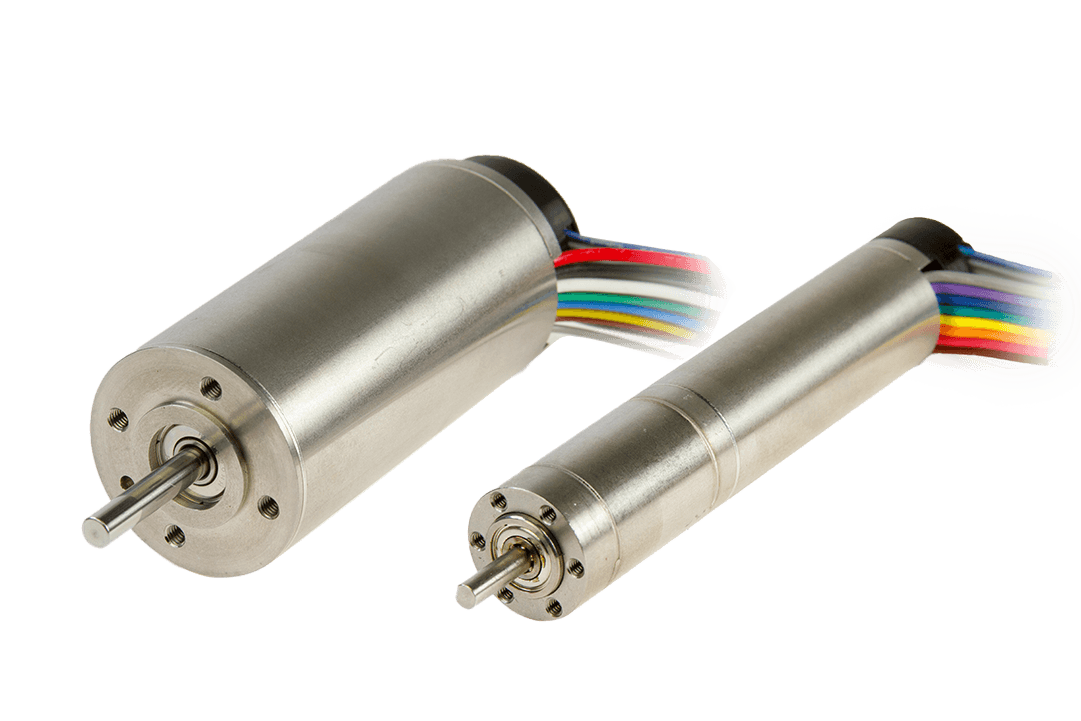

Zero Exposure

"Zero Exposure" technology from Lin Engineering is engineered to ensure optimal performance in extreme environments by minimizing the exposure of motor internals and electronics to adverse environmental factors. This includes our IP-rated motors, which are designed to prevent the ingress of moisture, dust, and other contaminants, protecting the essential components from damage and wear. Additionally, our vacuum-rated motors are specifically tailored to operate efficiently in vacuum environments with minimal outgassing. These motors are constructed to maintain integrity and functionality in settings where conventional motors might fail, making them ideal for applications requiring high reliability and minimal environmental interaction.