Surgical Robot Stepper Motor Case Study

Surgical Robot Stepper Motor Case Study

When selecting a stepper motor for an application in the medical industry, many factors need to be considered. After all, equipment that is used in the medical field relies on high-quality components that provide consistently high performance. These applications, whether they are pumps, life science-related, or general lab automation, are often used in environments that are crucial to patients and technicians alike. In this case study, we will take a sneak peek into an application involving surgical robotics!

Lin Engineering was approached by a customer whose main objective was to allow healthcare professionals to easily and accurately control robotic arms, which in turn would be responsible for conducting a variety of patient-related procedures. The customer had already worked with prototypes from a different stepper motor manufacturer and found the following problems:

1. The stepper motor exhibited too much resonance (or vibration)

2. The excess vibration resulted in uneven movements and inaccurate motion

3. The stepper was too loud

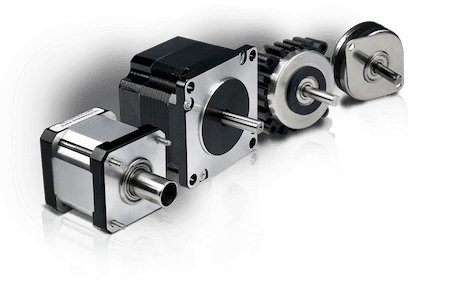

Lin Engineering’s application team reviewed the information that was critical to the customer’s application; namely, the speed range at which the stepper motor would typically be operated, the space constraints of the application, and how much power (i.e. current and voltage) was being applied to the stepper motor. After some initial calculations and testing, it was determined that the customer’s required operating speed range was at or near that particular motor’s resonant frequency. This resulted in higher-than-normal vibration/resonance and a high-pitched noise. All stepper motors have an inherent amount of resonance which typically occurs at lower speeds. There are certain measures that can be taken from both the motor standpoint and the driver/controller aspect in order to help reduce this vibration. From the motor aspect, applications engineers at Lin Engineering typically look at the following options:

1. Optimizing the motor’s internal winding in order to shift the motor’s resonant point outside of the customer’s operating speed range

2. Adding a mechanical damper in order to lower the vibration amplitude and shift the resonant frequency.

3. Changing the microstepping setting of the step motor driver.

In this situation, options 2 and 3 were not suitable for the customer’s application given that there were size constraints and the customer did not want to change any of their driver and controller settings. Optimizing the motor’s winding was the preferred option as:

1. Successfully implementing this type of solution would help the customer avoid making any costly changes to their instrument

2. The customer could save time and valuable resources by not having to revert to an extensive trial-and-error process

3. Obtaining a custom winding comes with no additional cost; just better performance

The applications engineering group at Lin was able to design a new winding that essentially shifted the resonant point away from the primary operating speed. Doing so got rid of the high pitch noise the stepper motor was previously exhibiting. Furthermore, the mechanical vibration was also reduced resulting in smoother motion and more accurate steps/movement.

News

Continue Reading

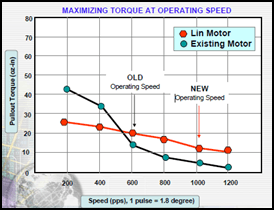

The Influence of Operating Speed on Stepper Motor Selection

Frequently, when it comes to step motor selection, users will select a motor with the highest holding torque rating, assuming that it will give them optimal performance. However, it is an improper practice to choose a motor based on holding torque alone. In fact, the step motor with the highest holding torque in many situations can prove to be a poor choice, especially when trying to maximize torque at desired operating speed.

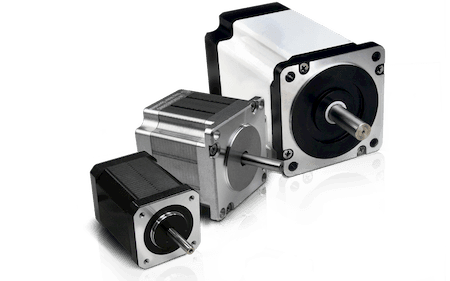

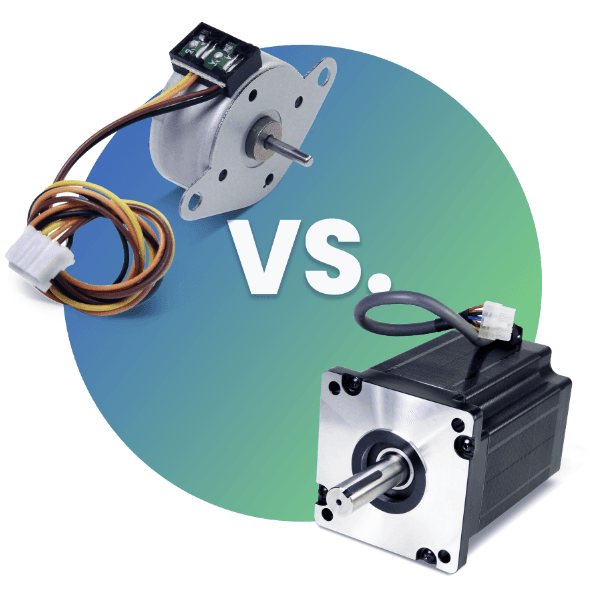

Choosing the Right Stepper Motor: PM Stepper or Hybrid Stepper?

When it comes to selecting the right stepper motor for your application, there are two primary types to consider: permanent magnet (PM) stepper motors and hybrid stepper motors. Both types have their advantages and disadvantages, and the choice ultimately depends on your specific application requirements.