Reduce Your Chances of Electric Motor Overheating

Reduce Your Chances of Electric Motor Overheating

The first thing to note concerning heat inside a motor is that you can’t measure it through the motor’s outside temperature. Design temperature ratings found in technical specifications are concerned with the hottest area within the motor’s windings, not how much of that heat is transferred to the motor’s outer surface. Heat transfer has more to do with the frame size, mass, and design—ribbed or smooth frame, open or closed frame—that vary greatly from one motor design to another. Any motor’s frame surface is a quilt of hot and cool spots often directly related to internal and external air circulation patterns. The bottom line is that the external temperature of a motor has little to do with the heat concerns that may be present inside the motor.

Motor Windings

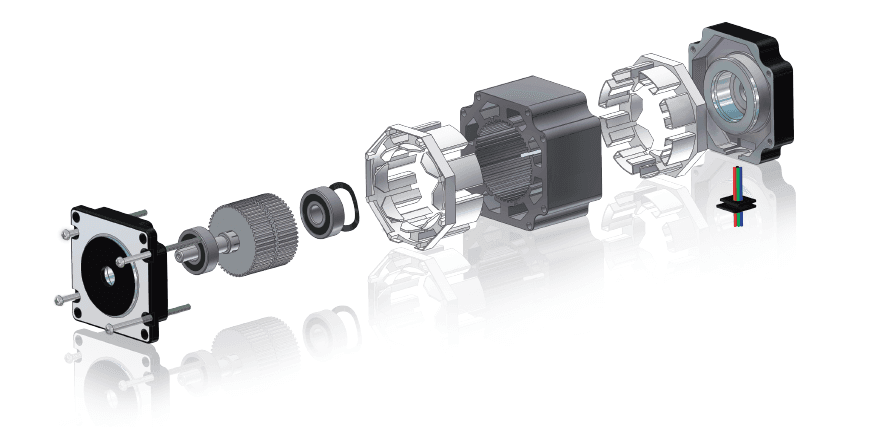

The specified operating temperature of a motor has to do with the winding temperature. In NEMA frame motors, insulation is used to separate electrical components and to prevent short circuit anomalies that facilitate winding burnout and motor failure. NEMA motor insulation includes the magnet wire coating to insulate coil wires from each other; slot cell and phase insulation typically made of high-strength polyester sheets that provide phase-to-ground protection; and insulating varnish that offers moisture resistance. All of this insulation is necessary but can’t protect the motor from other factors, such as vibration, chemicals, and abrasives that might be present in the motor’s operational environment.

Motor windings are designed to operate at particular temperatures that assure long life of 20,000 hours on average. NEMA standards set temperature standards for motors using a variety of enclosures that are based on thermal insulation classes. The association site provides access to information that summarizes the standards for maximum winding temperatures a motor can rise to and still offer long insulation life. Note that a lot of industrial-grade motors provide a higher overload tolerance, which may allow them to operate safely at higher temperatures.

Environmental Considerations

Be aware of the location of your motor, how it’s installed, and what conditions it operates under. Motors need to be mounted using a solid base to reduce the chances of misalignment and the increased friction and vibration that can occur. These factors lead to motor strain and therefore the potential for overheating. Be sure that there is adequate airflow around the motor and that there are no particles in the air if the motor isn’t sealed. Keep motors away from direct airflow from heaters or air conditioners, as well as open windows where humidity or precipitation can enter the area easily. Note that high altitudes can also affect your motor because the thin air offers less cooling capability.

Use the right enclosure for the environment your motor will be working in. For example, ventilated enclosures—for airflow cooling—might be the wrong approach if your environment is filled with dust and debris that can easily get inside the motor and clog up the works. And a sealed enclosure might be the wrong choice if the motor is located in direct sunlight during most of the daylight hours.

Clean power is as important as the other factors mentioned here. Many electronic drives focus on mitigating harmonics and supplying good power quality. Yet, if there are any voltage imbalances between phases greater than two percent, damage to windings can occur. Also consider running your motor at around 80 percent of the load that is recommended, so that changes that happen over time can be compensated for. Another concern is low voltage occurrences which can cause the motor to draw more current. Similarly, running the motor for an extended period of time with high voltage can saturate the motor’s core, leading to overheating.

Safety Features

Correctly sized, installed, and applied motors operating under standard conditions offer few reasons for concern when it comes to overheating. That doesn’t mean unanticipated environmental changes won’t occur. After all, equipment gets old, is misused, and could be subject to unusual shock or vibration from other areas of a system. This is why application engineers often install overload protectors such as resistance temperature devices or thermocouples as part of their motion system design. This approach assures that motors are taken off-line prior to a catastrophic failure.

If your safety device is continually shutting down the motor, it could be that the motor was not sized properly and is overheating. A quick check for the current draw on the motor will tell you if it is working properly. Check your current reading against the specifications listed on the motor’s nameplate rating to be sure that it is operating within range.

Be sure that your motor manufacturer is using the latest technologies for their winding design and that additional insulation is employed if your motor will be operating under higher than normal stress. Motor design, though, goes beyond simply insulation protocols. Users must consider frame type, environmental conditions, and the power being delivered to the motor. Making sure your motor has maximum lifecycle expectancy means your application will be equally safe against unnecessary and early failure.

News

Continue Reading

4 Critical Motor Requirements Needed for a LiDAR System

LiDAR is a critical component for driverless vehicles so that they can “see” and react to obstructions that might occur while driving from one place to another. The motor, as a key component to the system, must meet tight application requirements in order to facilitate the requirements of the system.

Reducing Electric Motor Weight

Today’s manufacturing equipment needs to have a smaller footprint, offer superior performance, and weigh less than ever before. Weight is an important factor not only because it aids in providing greater efficiencies for speed and torque, but for portable equipment, including table- and desk-top systems such as 3D printers, simulation systems, and medical lab equipment. In a motion system, motor weight can be very important.