What is a Slotless Motor?

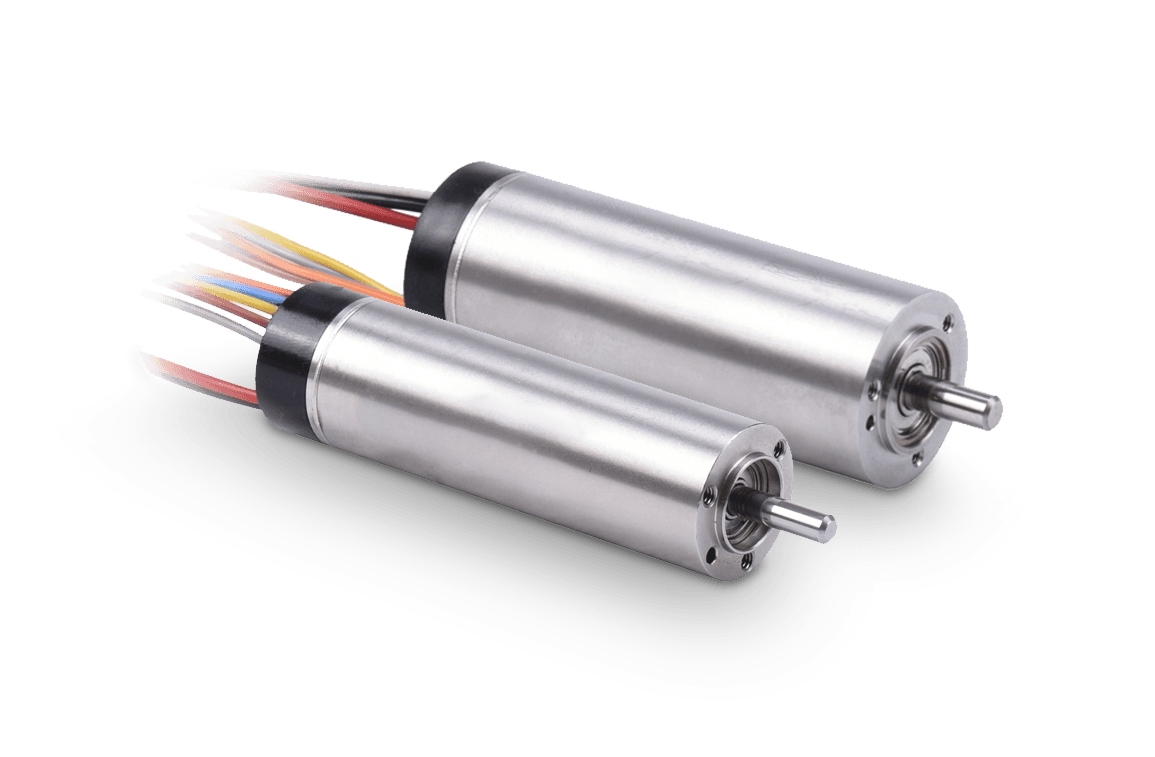

Electric motors are essential components in a wide range of devices, from household appliances to industrial machines. The design of electric motors has evolved significantly over the years, from the traditional brushed motors to the more advanced brushless motors. One of the latest developments in electric motor technology is the slotless motor. Below we will explore what slotless motors are, how they work, and their advantages.

What is a Slotless Motor?

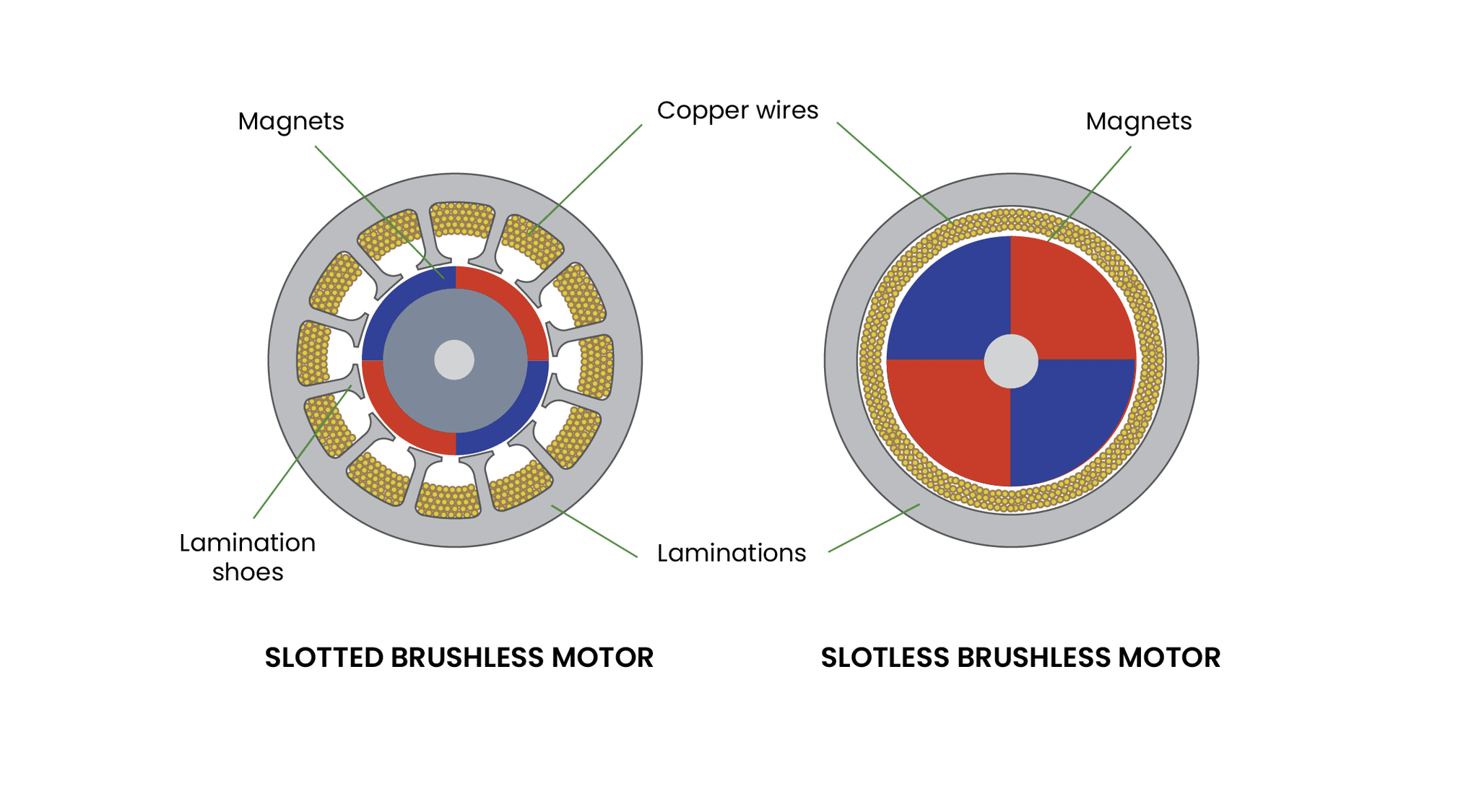

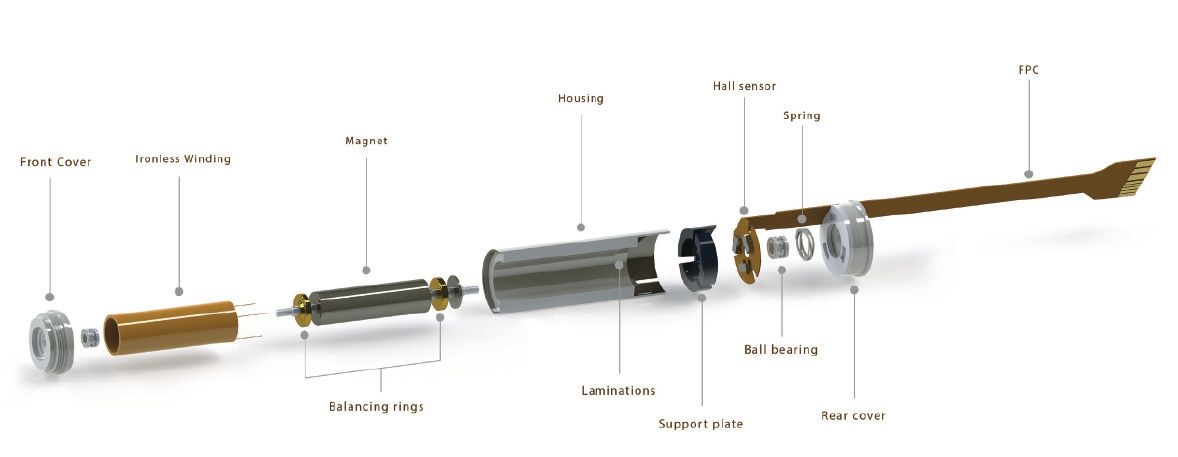

A slotless motor is an electric motor that does not have slots on its stator, the stationary part of the motor that contains the windings. Instead, the stator is made up of a cylindrical or spherical core, which is wound with a continuous wire. The rotor, the rotating part of the motor, will have magnets embedded in it.

How does a Slotless Motor Work?

Slotless motors use the same basic principles of electromagnetic induction as other types of electric motors. When a current is passed through the stator windings, it generates a magnetic field that interacts with the magnetic field of the rotor, causing it to rotate. The absence of slots on the stator means that the magnetic field is more uniform and efficient, resulting in smoother and more precise motor operation.

Advantages of Slotless Motors

The absence of slots on the stator is what sets slotless motors apart from traditional motors. Without slots, there is no iron core, which reduces the amount of energy lost to heat and allows for higher efficiency. The absence of slots in the stator also reduces the magnetic flux leakage, leading to higher motor efficiency. This means that slotless motors can convert a higher percentage of the input power into useful work, resulting in lower energy consumption and operating costs.

One of the main advantages of Slotless motors is they have a higher power density than traditional motors. This means that they can produce more torque and power for their size, making them ideal for applications that require high performance in a compact package. Slotless motors also have a faster response time and better precision control, which makes them suitable for applications that require accurate positioning and speed control.

Compared to traditional motors, slotless motors have a smoother and quieter operation. The absence of slots in the stator results in a more uniform magnetic field, which reduces noise and vibration levels. This makes slotless motors ideal for applications where noise and vibration are critical factors, such as medical equipment, laboratory automation, and robotics.

Slotless motors require less maintenance compared to traditional motors. The lack of brushes in slotless motors reduces the need for maintenance, resulting in a longer motor lifespan and reduced downtime. This makes slotless motors ideal for applications where reliability and uptime are critical factors, such as aerospace, industrial automation, and automotive.

In contrast to traditional motors, slotless motors exhibit a lower thermal resistance, allowing them to efficiently dissipate heat. As a result, they offer enhanced reliability and extended lifespan. Consequently, slotless motors are particularly well-suited for applications that involve high temperatures and challenging environments, such as those found in the aerospace, industrial automation, and automotive sectors.

Applications of Slotless Motors

Slotless motors have become increasingly popular in recent years due to their numerous advantages over traditional motors, including higher efficiency, improved performance, reduced noise and vibration, lower maintenance, and better thermal management. As a result, slotless motors are being used in a wide range of applications across various industries.

The medical industry frequently employs slotless motors due to their dependability and silent performance. These motors are utilized in a range of medical equipment, including surgical tools, diagnostic equipment, and medical pumps. Furthermore, slotless motors are well-suited for medical devices that necessitate high precision and speed, such as blood analyzers and centrifuges.

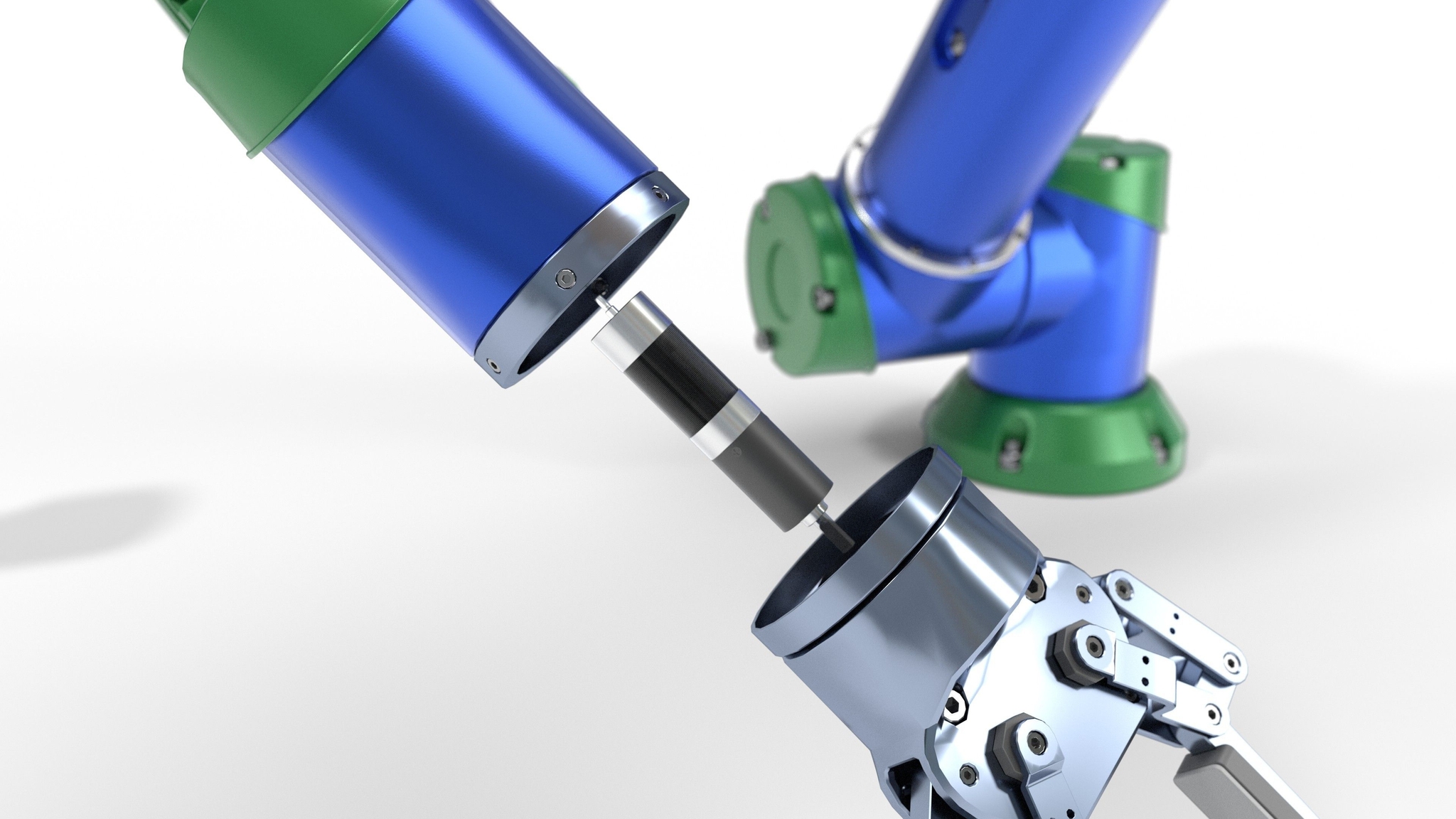

Robotics use slotless motors in a variety of applications due to their high power density, precision control, and low maintenance requirements. They are used in various applications, including robotic arms, grippers, and actuators. Slotless motors are also ideal for robots that require high speed and accuracy, such as drones and autonomous vehicles.

Due to their excellent reliability, minimal maintenance needs, and ability to function in severe conditions, slotless motors are frequently used in the aerospace and defense sectors. They are used in various applications, including actuators, pumps, and generators. Slotless motors are also ideal for aircraft and spacecraft that require high power and efficiency, such as electric propulsion systems.

Slotless motors are widely used in industrial automation applications due to their high efficiency, low maintenance requirements, and ability to operate in harsh environments. They are used in various applications, including robotics, conveyors, and packaging equipment. Slotless motors are also ideal for industrial equipment that requires high speed and precision control, such as CNC machines and 3D printers.

In the automotive sector, slotless motors are becoming more popular due to their superior efficiency, low maintenance requirements, and ability to function in severe conditions. These motors are employed in various applications, including electric power steering, braking systems, and HVAC systems. Additionally, slotless motors are well-suited for electric vehicles that necessitate high power and efficiency, such as electric motors and generators.

Slotless motors are a technological advancement that has revolutionized the way motors are designed and operated. The absence of slots in the stator and rotor has allowed for higher efficiency, improved performance, reduced noise and vibration, lower maintenance, and better thermal management. These advantages have made slotless motors a popular choice in various industries, including medical equipment, robotics, aerospace and defense, industrial automation, and automotive.

As technology continues to advance, slotless motors will likely become even more widely used, as their advantages become more well-known and their applications continue to expand. Whether it's in medical equipment, aerospace, and defense, or electric vehicles, slotless motors offer a range of benefits that traditional motors simply cannot match. As such, they represent a significant step forward in motor design and an exciting opportunity for further innovation and growth in a variety of industries.