Low Detent Torque Hybrid Stepper Motors

Z-Series Zero Detent Torque Hybrid Stepper Motors

EXTREMELY ACCURATE AND SMOOTH

- NEMA 17, 0.9 degree Step Angle

- Virtually Zero Detent Torque

- High Step Accuracy

- Reduced Resonance

- Up to 28 oz-in (0.20 N-m) Holding Torque

We've Reinvented the Step Motor

Conventional hybrid stepper motor utilizes a permanent magnet in the rotor. Our patented design uses a ring magnet in the stator instead. This drastically reduces the detent torque (unenergized drag torque) because the magnetic flux path is able to reach over the stator windings and go through only the outer edge of the rotor. Reducing detent torque improves accuracy, smooth operation and reduces noise. Best of all, modifying the magnet location does not change the dynamic torque.

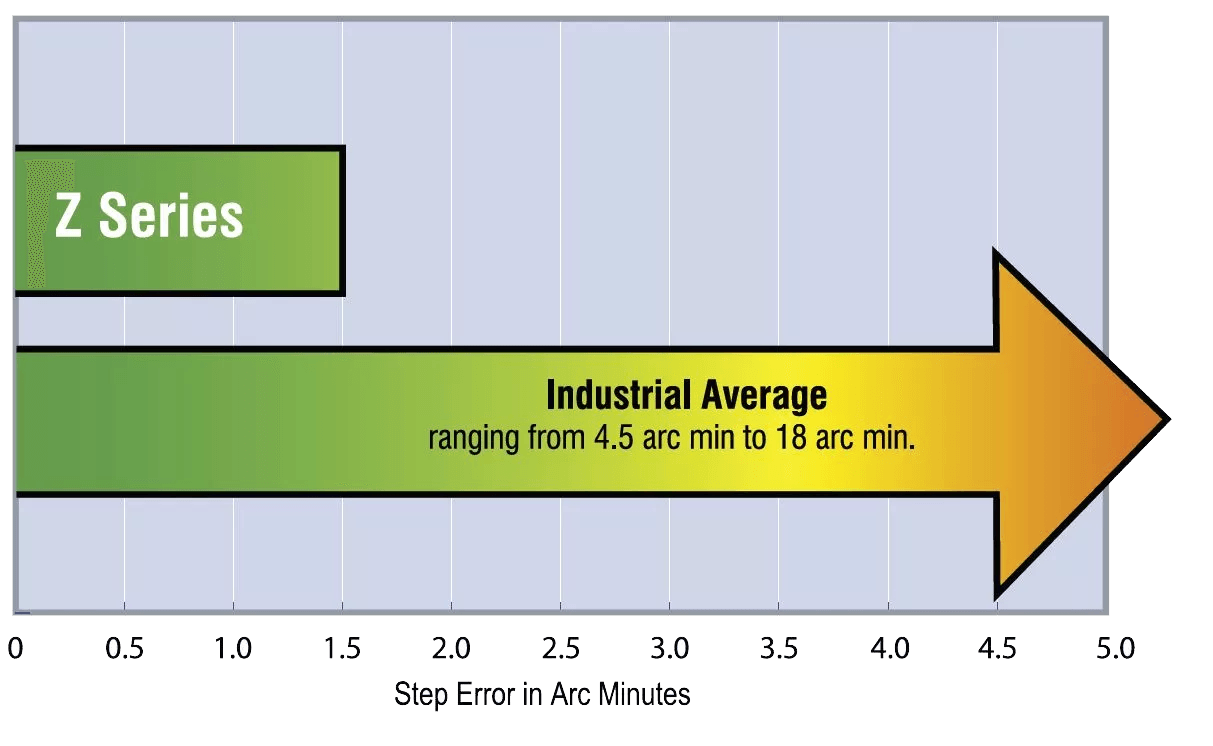

Extreme accuracy

Z-Series motor maintains ±1.5 arc minutes error under 64x microstepping. Industry average can range from ±4.5 to ±18 arc minutes in 0.9° step motors.

Quiet Operation

By eliminating detent torque, the motor operates substantially quieter than regular hybrid stepper motor.

Application

By Z-Series motors are perfect for any application which requires extreme precision, smoothness, and quiet operation.

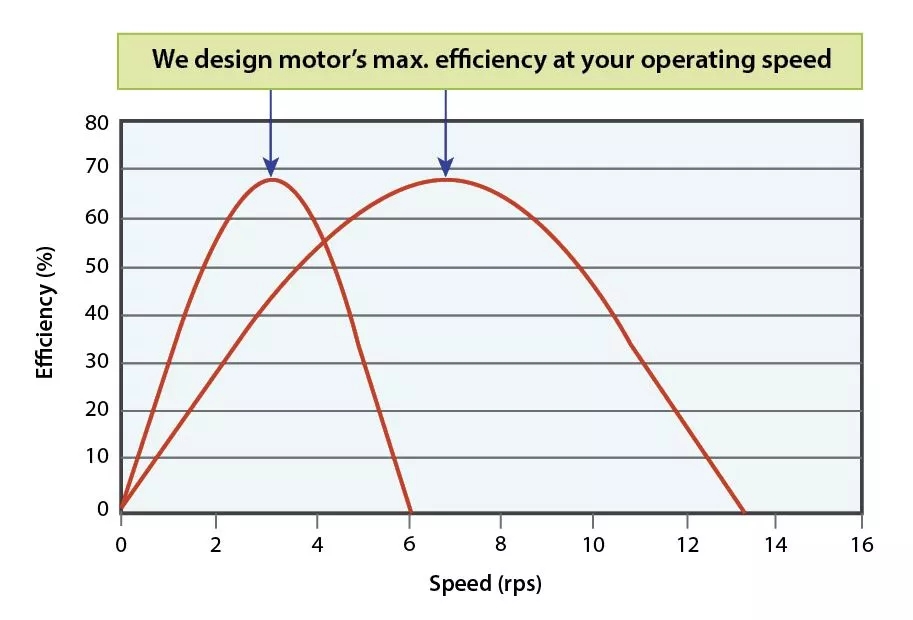

Custom motor without custom price tag

What others consider “custom” is standard for us. We can choose a winding that will meet your requirements for torque, speed, and current.

ZN417 - Extremely Accurate And Smooth

- NEMA 17, 0.9 degree Step Angle

- High Step Accuracy

- Low Vibration/Resonance

- Virtually Zero Detent Torque

- Up to 28 oz-in (0.20 N-m) Holding Torque

- Smooth and Quiet Operation

ZH417 - Large Diameter Hollow Shaft

Same benefits of Z-Series motor with addition of:

- Hollow Shaft up to 11 mm diameter

- No Torque Loss Due to Large Hollow Bore

- Up to 33.5 oz-in (0.24 N-m) Holding Torque

- Smooth and Quiet Operation

Speak with one of our motion control experts about your next project.