productsstepper motorsspecialty motorsvacuum rated motors

vacuum chamber stepper motors

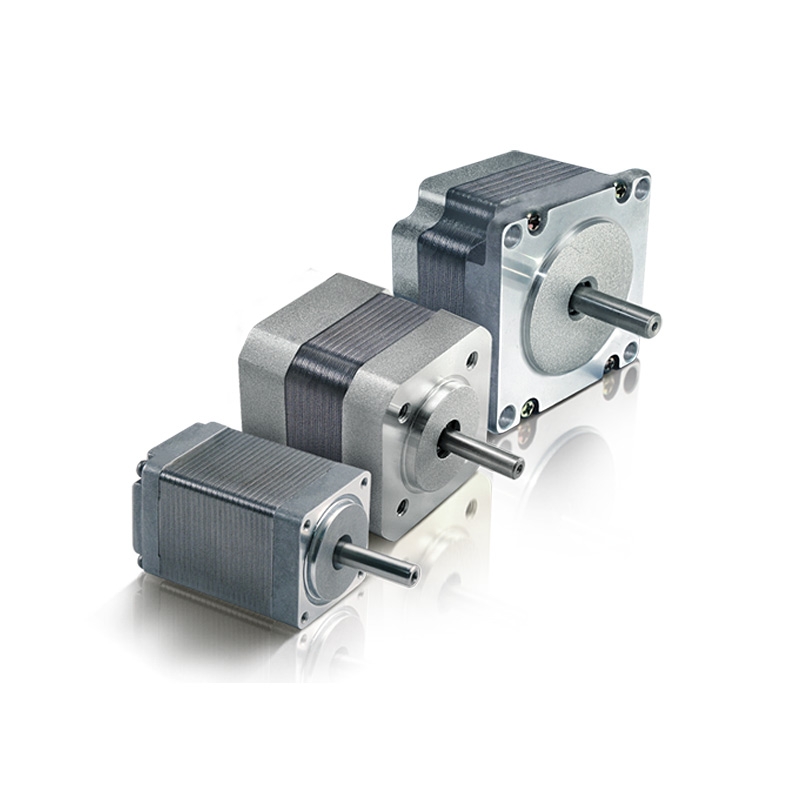

Vacuum Rated Stepper Motors For Vacuum Chamber Application

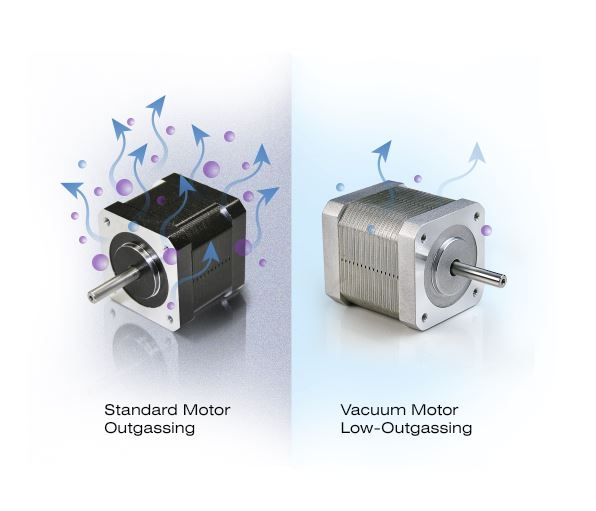

When you are searching for vacuum-rated stepper motors, consider the overall industrial or aerospace vacuum environment where you will be using the vacuum motors. Whether for use inside a vacuum chamber or in the vacuum environment of space, you’ll want to consider heat generation and outgassing contamination. Vacuum compatible motors manage heat through the use of special motor design and specific winding techniques developed specifically for vacuum applications. As a vacuum motor supplier, we’ve spent years researching and developing the right product for your needs.

Various contaminants that are trapped inside paints, coatings, and greases, can get released into the environment when air is removed from the environment. Our vacuum compatible stepper motors are design using low-outgassing materials to eliminate this concern, and assembled in a cleanroom environment using our proprietary assembly process. As a solution to vacuum motor applications, this approach also eliminates the majority of concern about contaminants entering the system.

We use proprietary motor assembly process to manufacture their industrial vacuum motors and aerospace vacuum motors, and we’ve compared our results with major competitive devices in a positive flow chamber that measured outgassing levels. Our vacuum compatible motors repeatedly outperformed the competition, making them the cleanest motors on the market today. Contact us for specific information.

Vacuum Applications

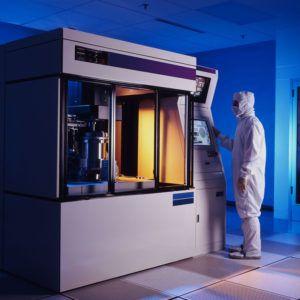

Specifically designed to be used in satellites and space craft, applications for our vacuum rated motors range from communication antennas to vehicle controls. We are an AS9100C registered manufacturer, and each motor is manufactured to meet the strict aerospace guidelines.

Since vacuum-rated motors do not introduce contaminants into the environment, they are perfect for sensitive environments where outgassing needs to be avoided, particularly during the semiconductor manufacturing process where even the smallest contamination can ruin the production yield.