cobots

BLDC Servo Motors for Collaborative Robots

Lin Engineering designs, engineers, and manufactures a variety of BLDC motors for collaborative robot applications. Cobot arms typically consist of compact multi-axis assemblies with unique requirements per axis, often requiring precise speed and position control, as well as the ability to hold position under varying loads. Lin Engineering offers cost-effective motor solutions for all axis of motion.

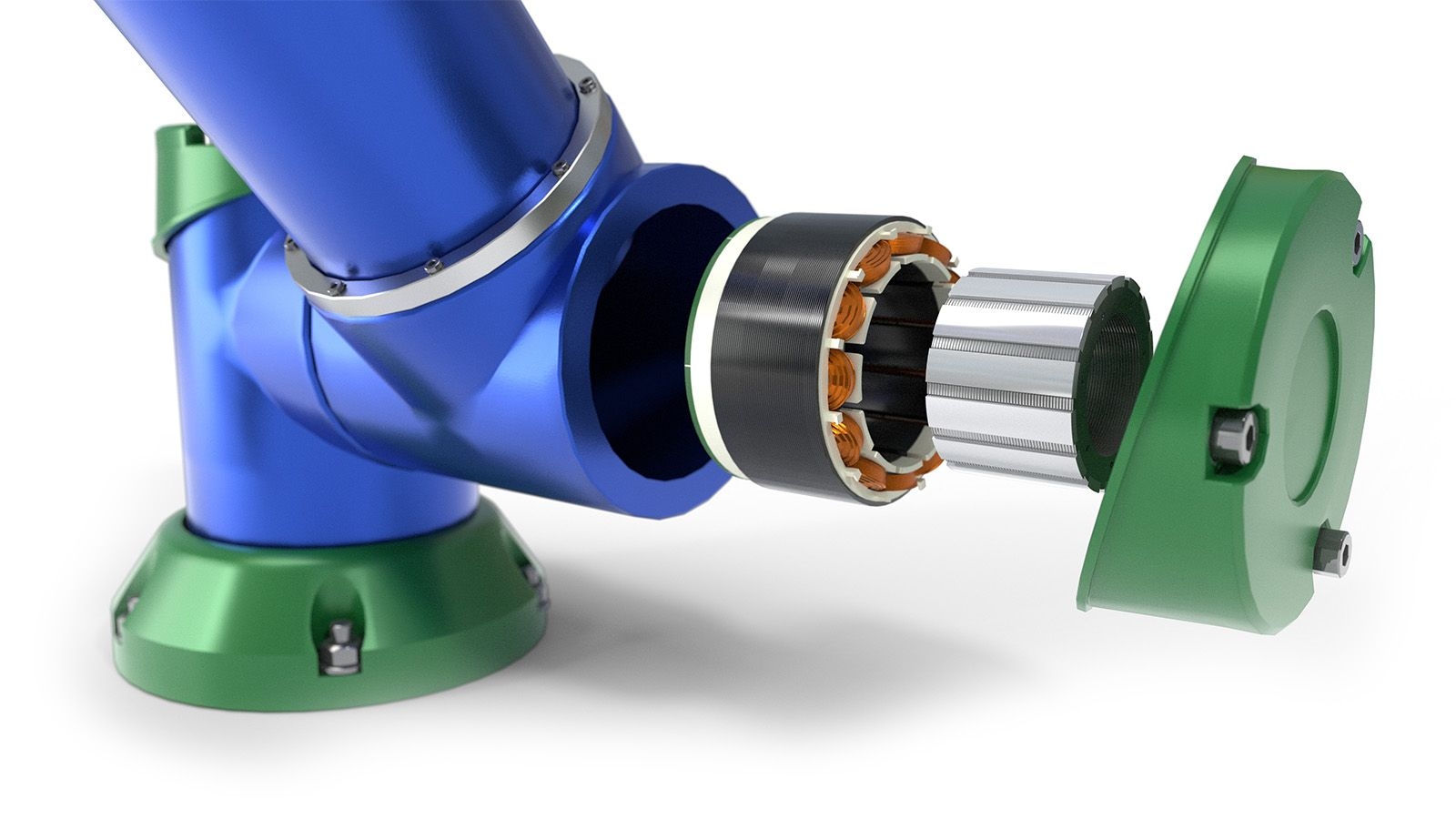

Frameless BLDC Motors

Frameless BLDC motors offer maximum engineering flexibility and excellent torque-to-size ratio. The rotor and stator are delivered as separate components that can be mounted directly to the assembly in which the motor is used.

- OD Range: 20 mm to 160 mm

- ID Range: 8 mm to 120 mm

- Continuous Torque Range: up to 2 Nm

- Peak Torque Range: up to 6 Nm

- Current Range: up to 12 Amps

- Voltage: up to 80V

- Speed: up to 20,000 RPM

- Thickness: up to 100 mm

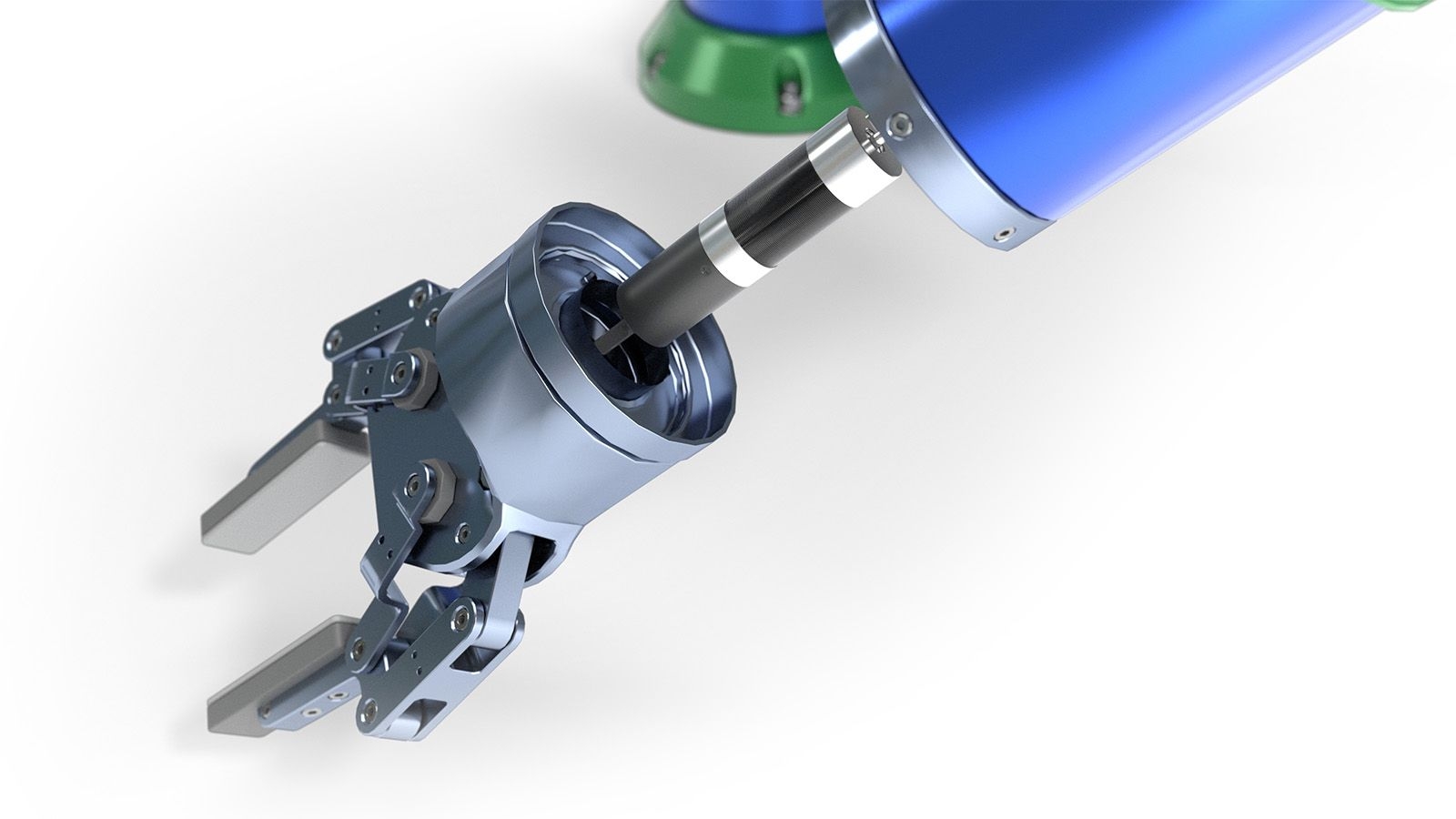

Slotless BLDC Motors

Slotless BLDC motors are the right choice for various Cobot material processing tools and attachments such as claws, grippers, and articulating appendages.

- Speeds up to 50,000 RPM

- High Efficiency and Torque

- Operational Lifetime of Up To 20,000 Hours

- Smooth and Silent Operation

- High Accuracy Motion Control

- 13 mm to 22 mm Diameter

- Gearbox, Encoder, and Driver/Controller Options Available

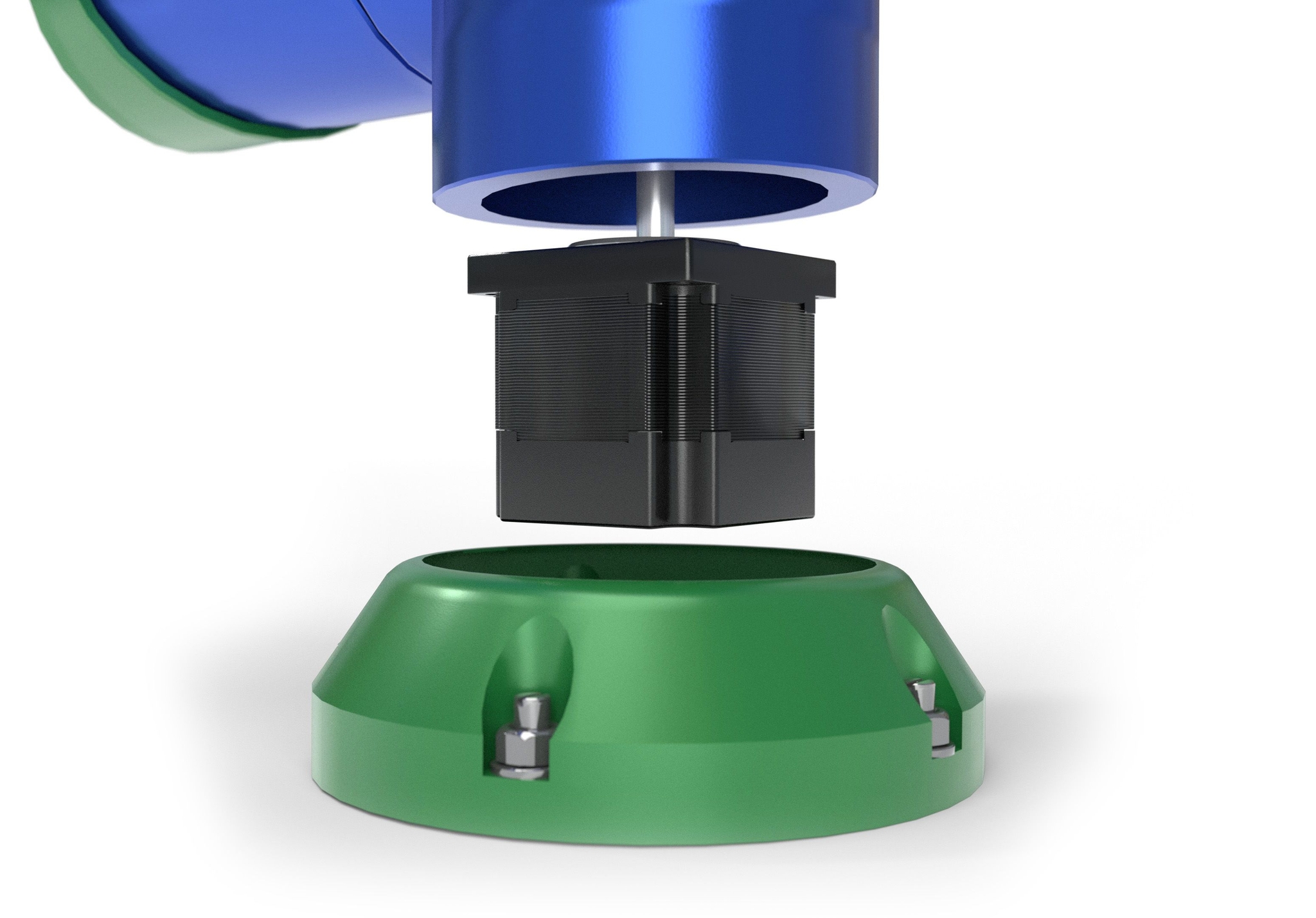

Standard BLDC Motors

Standard BLDC motors are offered in standard NEMA frame sizes and provide a wide range of speeds and smooth torque output.

- NEMA 17, 23, and 34 Mounting

- Wide Range Of Speed Control and Smooth Torque Output

- Excellent Speed Stability

- Small Size, High Power

- Low Temperature Rise, Low Noise, Low Vibration

- Long Life, Low Maintenance Costs

- Low Positioning Torque

- Energy Efficient

- Works With Planetary Gearboxes

- Custom Windings and Modifications Available

Servo BLDC Motors

Lin Engineering AC and D Servo Motors provide precise speed, position, and torque control. Available in 40 mm to 180 mm frame sizes with a rated output of up to 5,500 watts, and a rated speed of up to 3,000 RPM. Includes integrated 2,500 PPR Incremental encoder.

- Segmented winding technology for maximum power density

- Epoxy-encapsulated stator for optimal heat dissipation

- High energy skewed magnets for greater peak torque and speed control

- Double-bonded magnets and precision balancing for smooth, safe operation

- High-capacity bearings for long life with high radial loads

- IP65 Rating for durability

- Multiple encoder options are available

- Servo Motor Sizes: 40 mm to 180 mm

- Available in AC or DC

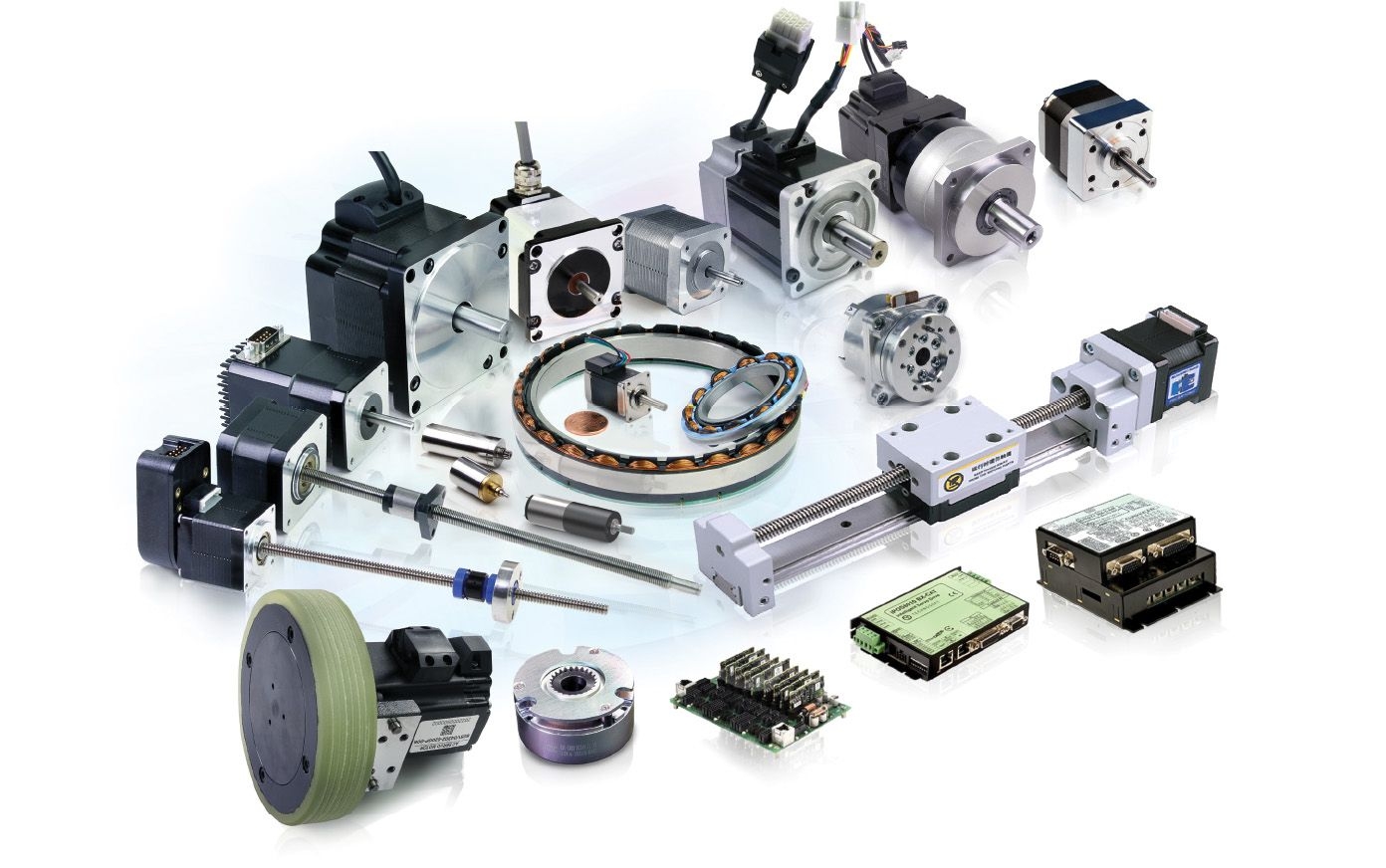

Extensive Lineup of Additional Products

Stepper Motors

- Hybrid Steppers

- PM Steppers

- Linear Actuators

- Integrated

BLDC Motors

- Conventional

- Frameless

- Servo

- Slotless

- Integrated

Drivers & Controllers

- EtherCAT

- CANopen

- Modbus

- EtherNet/IP

Value Add & Assemblies

- Gearboxes

- Wheel Motors

- Encoders

- Wire Harness

Many Configurations

- IP Rated/Sealed

- Vacuum

- Low and High Temp.

Why Lin?

Find Out Why More Engineers Are Choosing Lin Engineering

Proven Supply Chain And Capacity

Motor Production

in California

Full Value Add Options

& Assemblies

Over 30M motors

produced annually

Rapid Prototypes &

California Based Kanban for Production

Unrivaled Support

Applications Engineers

throughout the US for local support

Full Design Engineering

out of California

U.S.

CORPORATE HEADQUARTERS

• Morgan Hill, California (Silicon Valley)

• Full Production of Motors & Assemblies

• Full Staff of Engineering and CAD

• On-Site Quality, Customer Service, and Sales

• Kanban and Safety Stock

• Prototypes in 2 Weeks

OVERSEAS

FACILITIES

• Over 1.5M sq feet of facilities space

• Locations in Vietnam, China and Europe

Ready to start on your next Cobot development project?

Let us know how we can help. Give us a call or fill out the request for a contact form in the sidebar, and one of our experts will connect with you soon.

Ready to start on your next Cobot development project?

Let us know how we can help.