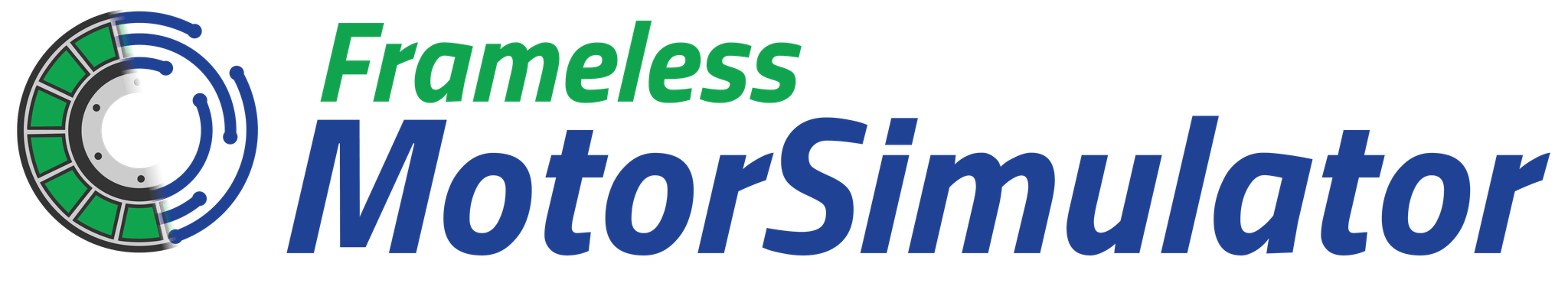

Lin Engineering’s Frameless Motor Simulator allows engineers to simulate frameless torque motor performance under specific operating conditions, significantly streamlining motor selection and design validation. Users can easily input and adjust critical parameters, including:

- Bus voltage

- Ambient temperature

- Maximum winding temperature

- Friction

- Winding adjustments

The simulator generates performance curves, accompanied by detailed performance metrics and electrical specifications. By removing guesswork, this tool helps engineers quickly identify the ideal motor solution, accelerating development cycles, enhancing design iteration speed, and shortening the time to market.

Getting started is easy.

Select any available Frameless Torque Motor part number, and start simulating performance.

About Lin's Frameless Motors

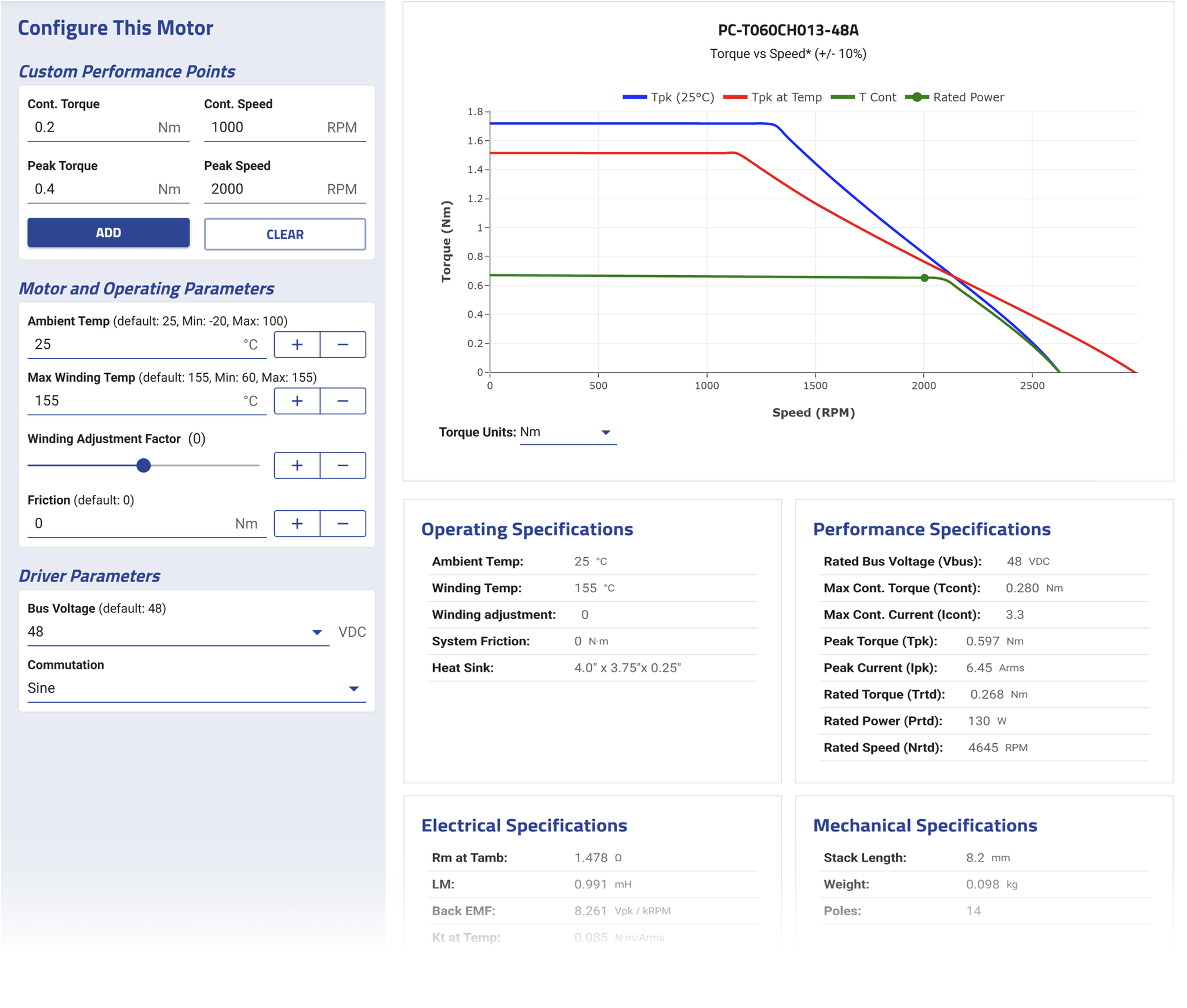

In the world of motion, precision, and reliability, our motors form the Core—the backbone of movement across diverse applications. The name "Core" reflects our belief that, whether driving a gimbal, supporting cobots, or powering demanding, high-performance systems, each motor series is an essential element that enhances the function and reliability of any system it serves.

FlexCore, PowerCore, and XtremeCore are engineered to be integral to your application, providing the foundation upon which efficiency, high performance and innovation are built.

- FlexCore - High Value designs meant for balanced performance.

- PowerCore - High Performance designs delivering high power density and efficiency.

- XtremeCore - Uncompromised power setting the industry standard for torque and power.

Why Choose Lin Engineering?

For over 30 years, Lin Engineering has supplied motors for robotics, aerospace, medical, and automation systems where performance and reliability are critical. Built under our 4.5 Sigma quality process and backed by U.S.-based prototyping with scalable global manufacturing, we deliver predictable lead times, long-term durability, and seamless integration — from 10 units to 10 million.

- USA-based Engineering and Manufacturing

- Based in Northern California, with engineering and manufacturing on-site

- Fast-track Prototyping

- Off-the-shelf motors and fast prototype turnaround

- Collaborative Engineering Support

- We can work closely with your team to create a customized solution for your specific application

- Engineered for Manufacturability

- Customized, plug-and-play motor solutions

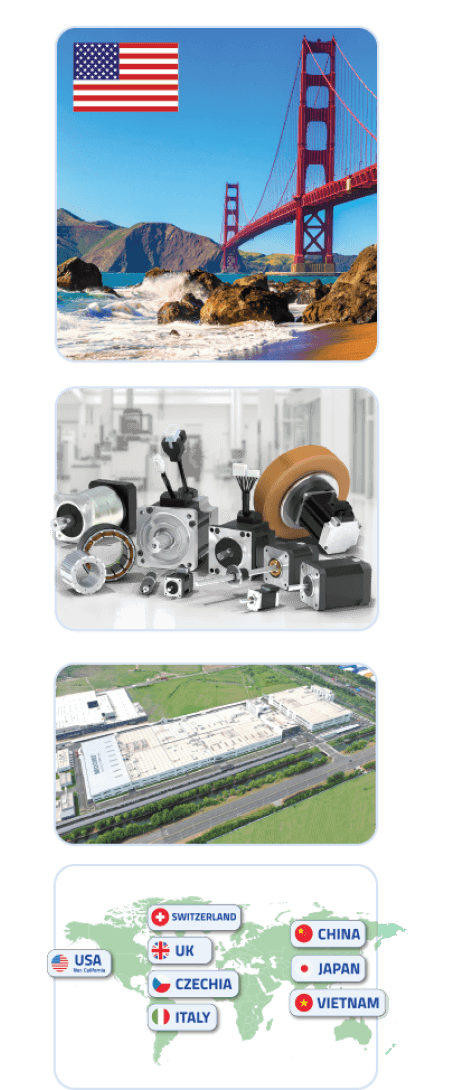

- Sustainable Supply Chain

- Long-term motor manufacturing support throughout the lifecycle of your product

- Scalable Production

- From 10 motors to 10 million motors

- Global Footprint

- Additional manufacturing facilities in Europe and Asia. 1.5 Million sqft of manufacturing space across 8 facilities

- Vertically Integrated

- We manufacture our own components, ensuring supply chain stability and on-time delivery