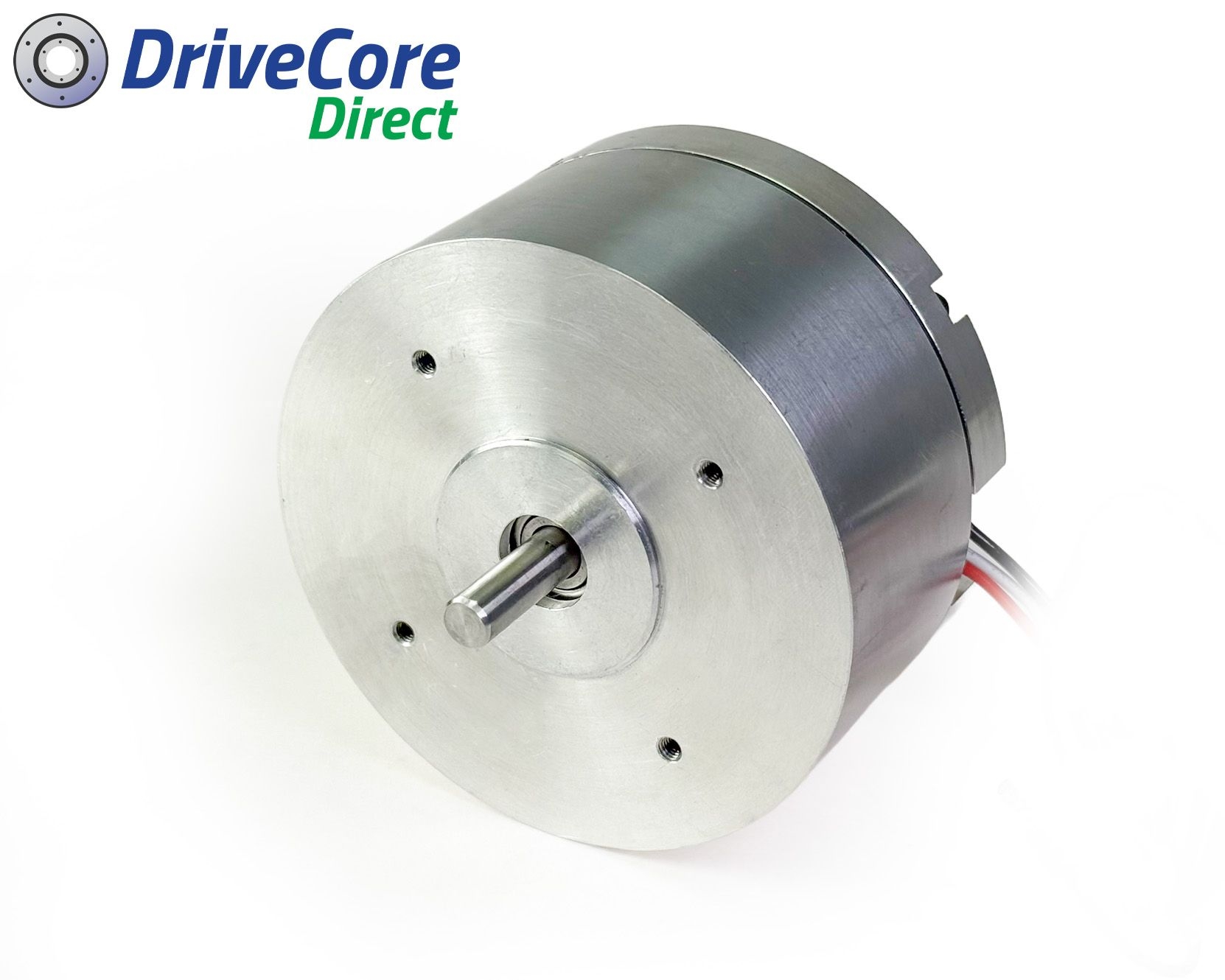

DPC-T085CH026-48A

Direct Drive Rotary Actuator

Specifications:

- 97.7mm OD

- 53.5mm Length

- 3.13Nm Rated Torque

- 8.63Nm Peak Torque

- 48VDC Bus Voltage

Features and Benefits:

- High torque to weight ratio

- Solid shaft

- Compact & lightweight

- Encoder, brake, strain wave gear, hall sensor and thermistor available

Features and Benefits

The DriveCore Direct (Solid Shaft) delivers precise, compact direct-drive motion using Lin Engineering’s high-torque frameless motor technology in a fully housed design. With exceptional torque density, zero cogging, and a robust solid output shaft for secure mechanical coupling, it simplifies integration while providing reliable, space-efficient actuation for robotics and automation.

Dimensional Drawing

Specifications

| Bus Voltage (Vbus) | 48 VDC |

| Rated Torque (Trtd) | 3.13 Nm |

| Peak Torque (Tpk) | 8.63 Nm |

| Max Cont. Current (Icont) | 5.23 A |

| Peak Current (Ipk) | 14.35 Arms |

| Rated Output Speed (Nrtd) | 606 RPM |

For detailed specifications or application-specific guidance, please contact Lin Engineering directly. Our team will provide the technical data and support you need. Click Here

Customized to Your Application

DriveCore motors can be tailored to match your exact performance and integration needs:

- Winding configurations for specific torque–speed profiles

- Solid shaft or hollow thru-bore options

- Gear ratio selection

- Encoder and brake options

- Custom connectors, cabling, and mounting interfaces

- Thermal management adaptations

Get a motor built for your design — not the other way around.

Applications

From AGVs and AMRs to cobot arms, humanoids, exoskeletons, and surgical platforms — this actuator delivers zero backlash, high torque density, and compact cylindrical packaging with a large thru-bore for simplified integration.

Built on Lin Engineering’s high-Km frameless motor technology, it provides smooth, cog-free motion with minimal torque ripple, ensuring precise positioning and lifelike control. Designed for durability across millions of load cycles, it maintains consistent performance under real-world duty cycles with optimized thermal management for continuous operation. Configurable options include gear ratios, encoders, and brakes, allowing the actuator to be tailored to your torque–speed envelope and application requirements. Manufactured under Lin’s 4.5 Sigma quality process, it offers engineers a proven, reliable foundation for mission-critical designs where precision, efficiency, and long service life are non-negotiable.

Why Choose Lin Engineering?

For over 30 years, Lin Engineering has supplied motors for robotics, aerospace, medical, and automation systems where performance and reliability are critical. Built under our 4.5 Sigma quality process and backed by U.S.-based prototyping with scalable global manufacturing, we deliver predictable lead times, long-term durability, and seamless integration — from 10 units to 10 million.

- USA-based Engineering and Manufacturing

- Based in Northern California, with engineering and manufacturing on-site

- Fast-track Prototyping

- Off-the-shelf motors and fast prototype turnaround

- Collaborative Engineering Support

- We can work closely with your team to create a customized solution for your specific application

- Engineered for Manufacturability

- Customized, plug-and-play motor solutions

- Sustainable Supply Chain

- Long-term motor manufacturing support throughout the lifecycle of your product

- Scalable Production

- From 10 motors to 10 million motors

- Global Footprint

- Additional manufacturing facilities in Europe and Asia. 1.5 Million sqft of manufacturing space across 8 facilities

- Vertically Integrated

- We manufacture our own components, ensuring supply chain stability and on-time delivery

Work With Us On Your Next Project

Work directly with Lin Engineering’s team to design a motor optimized for your torque, thermal, and duty-cycle requirements.

Contact us for a quick, no-obligation feasibility review — let’s discuss your project.