About Lin Engineering

Why Choose Lin Engineering?

Motor Engineering and Manufacturing Here In The USA

For over 30 years, Lin Engineering has been developing capabilities to design and manufacture a wide variety of motion control products. Starting off with a wide breadth of hybrid step motors, our product line has also grown to encompass linear actuators, BLDC motors, Servo motors, Frameless motors and Slotless motors. Beyond that, we are able to provide a large array of value add / sub-assembly components such as encoders, gearboxes, wire harness and the like. Our products and solutions can be found in a variety of industries including Aerospace, Aviation, Life Science, Robotics, Autonomous Vehicles, along with Industrial and Agricultural applications.

Over the years we have developed a reputation of providing unrivaled application support, consistent quality and unique products that can be easily configured for our customers' specific requirements. We can offer unique designs for demanding applications: high accuracy, high life / reliability, sealed / IP rated motors and even low outgassing. Working with Lin Engineering means you are partnering with a company whose outreach includes a global supply chain network that is capable of supporting small prototype runs in the USA to millions of motors in volume production.

Everything starts with our facility in Morgan Hill, California which is conveniently located in the heart of Silicon Valley. Not only do we have a full Engineering staff, there is also a local Quality team, Applications, Sales, Customer Service, and so much more. The crown jewel of it all? A California based manufacturing facility that proudly makes motors in the USA. For added support, we have a nationwide team of Applications Engineers and Account Managers that can provide you with the benefits of localized support.

Need even more reasons to consider Lin Engineering as your motor supplier?

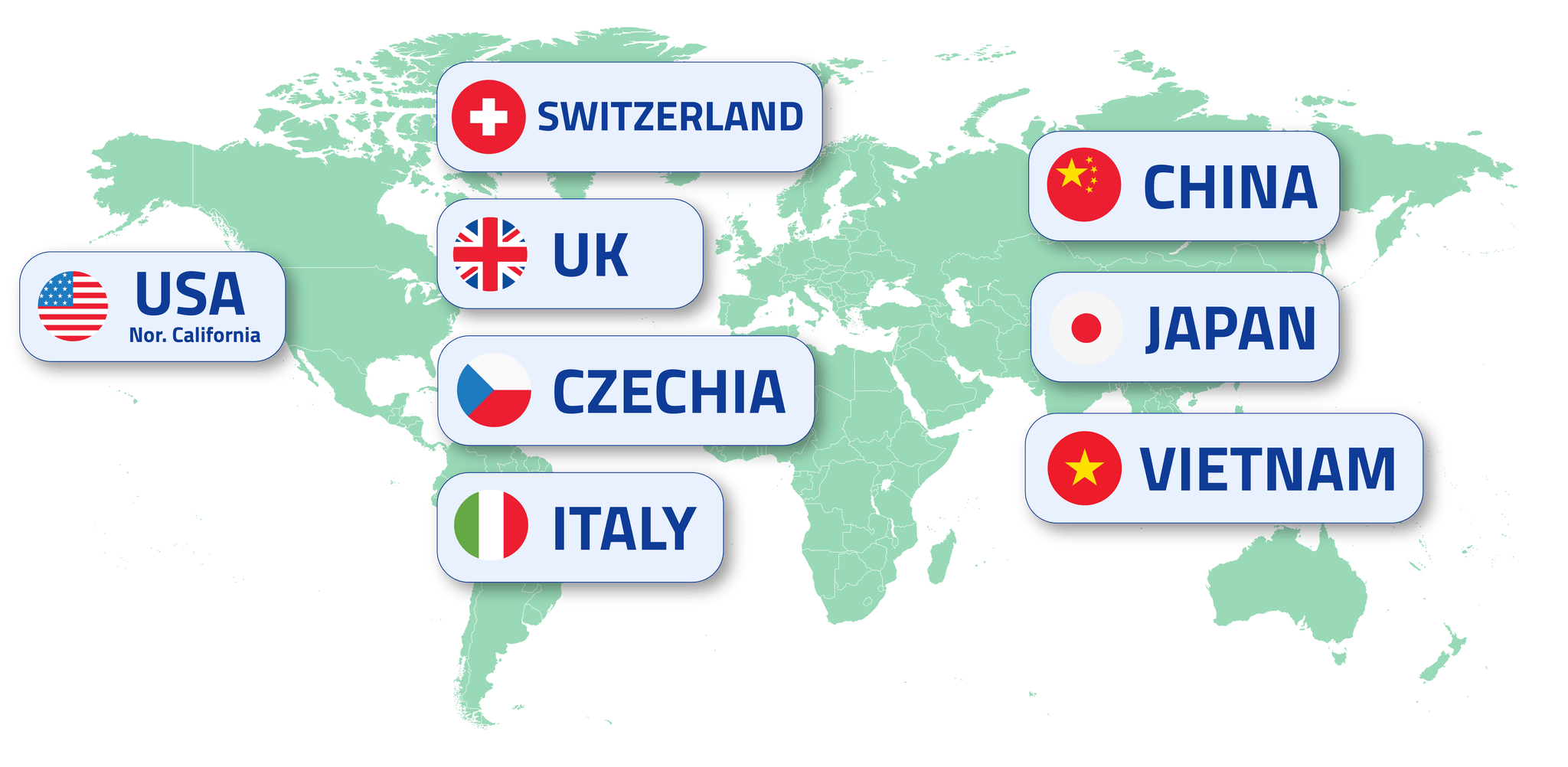

Global Footprint

Lin Engineering has a strong global footprint with 1.5 million square feet of manufacturing space across eight facilities, including additional locations in Europe and Asia. This extensive network enables scalable production, ensuring efficient delivery and support for customers worldwide.

EVERY DAY MORE ENGINEERS CHOOSE LIN ENGINEERING

This is how we earn your business and become a valued supply chain partner

UNRIVALED APPLICATION SUPPORT

- 98% application success rate

- 90% of prototypes shipped in

less than 2 weeks - California based support

OEM ENGINEERING SUPPORT

For OEM orders, we’ll work directly with your engineering team throughout the design phase of your project to ensure the best overall system optimization and motor fit while avoiding over-engineering.

MOTOR ENGINEERING

GET EXACTLY WHAT YOU NEED

In motion control, no two designs are the same. When you’re optimizing for the best efficiency, accuracy, or speed, you don’t want a motor that is close enough, you want a motor that meets your requirements precisely. This is exactly what we can provide: a motor with the exact specifications you need for your specific design or application.

INNOVATIVE SOLUTIONS

We’ve designed our motors to solve specific problems within your application. Our motors deliver more torque, smaller

size, higher speeds, increased accuracy, and reduced noise and resonance—among many more benefits.

HIGH PERFORMANCE

- Highest torque output

- High accuracy = no skipping steps

- Reduced vibration and resonance

MANUFACTURING SUPPORT

ON DEMAND ASSEMBLY

Our unique method of assembly allows us to stock a large selection of standard components that can be assembled in a multitude of ways for your specific needs. This allows us to assemble a motor that meets your exact specifications, with minimal lead time, and at a great price point.

MEET REQUIREMENTS

We manufacture and keep data with accordance to ISO9001:2015, AS9100D and many other standards. For this reason,

our motors can be found in numerous FDA and FAA-approved applications.

FAST PROTOTYPE TURNAROUND

Our Northern California manufacturing facility doubles as our prototyping facility. This gives us a much higher flexibility to try out different components and windings to ensure the motor will perform at its best. This also ensures that prototypes operate the same as the volume parts. Plus, we test each motor in real time.

SCALABLE MANUFACTURING VOLUMES

We grow with your needs. The benefit of multiple manufacturing facilities—within the United States and in Asia—allows us to maintain whatever volume you need, as well as handle spikes with minimal concern. Our Northern California facility is optimized for low to mid volume production, while our off-shore facilities are optimized for high volume production, which allows us to scale with your manufacturing requirements. As the demand for your product in the marketplace multiplies, our ability to provide what you need increases as well. Furthermore, we guarantee the identical quality assurance.

CONFIGURED SOLUTIONS

- Standard / off-the-shelf motors are easily accessible via the web store

- Easily configure your solution:

- Windings for efficiency

- Cabling and connectors

- Much more!

QUALITY DONE RIGHT

4.5 Sigma From Lin Engineering - a True Quality System

We've implemented 4.5 Sigma in order to accomplish the following goals:

• Establish a robust Mean Value Control System

• Perform incoming inspection at our supplier’s site

• Ensure quality products with every shipment

WE DESIGN, ENGINEER AND MANUFACTURE MOTORS

that solve specific problems within your application.

Ready to start on your next product development project?

Let us know how we can help.