What is a Servo Motor?

What is a Servo Motor?

As our technology advances, the use of robots and other autonomous applications in our daily lives increases as well. While cheaper robots use stepper or brushed DC motors, more advanced robotics require the use of servo motors. But what is a servo motor and why are they used in most industrial applications?

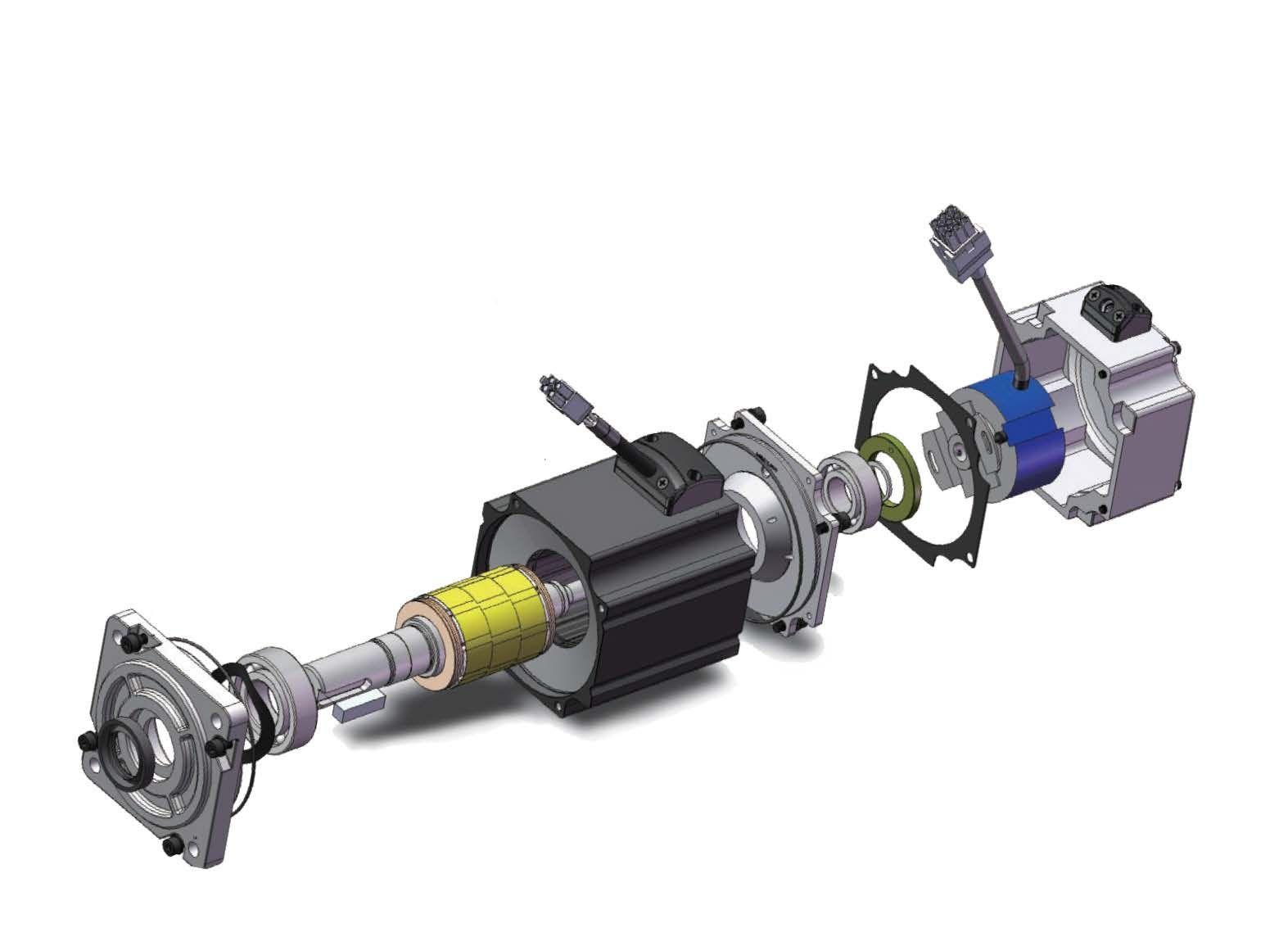

A servo motor is a self-contained electrical device that moves parts of a machine with high efficiency and great precision. In simpler terms, a servo motor is a BLDC motor with a sensor for positional feedback. This allows the output shaft to be moved to a particular angle, position, and velocity that a regular motor cannot do. However, a servo motor is only one part of a closed-loop motion control system. A complete motion system includes an amplifier, control circuit, drive gears, potentiometer, shaft, and either an encoder or resolver as well as the servo motor.

Servo or Stepper?

What makes a servo motor different from a stepper motor? While both kinds of motors can control speed and position, they are both designed for very different applications. Stepper motors have built-in steps allowing the controller to signal how many steps to make, however, this only works if the controller knows the position of the output shaft. Because of this, when a stepper motor is powered up the controller moves the output shaft to a known position or until it activates an end limit switch. A servo motor uses a sensor to know the position of its output shaft so that when it is powered on it can immediately go to the desired position.

The design of a stepper motor limits its performance due to the limited feedback sensors. If the system is overloaded a stepper motor could skip steps causing positional errors and having to recalibrate the motion system. With a servo motor, the encoder and controller track the position of the output shaft so any errors can be corrected.

Another differentiation between a servo and a stepper motor is their top speed and torque at speeds. A stepper motor provides the most torque when it is not moving, referred to as holding torque. As the speed of the output shaft increases, the torque is drastically reduced. A servo motor has a much higher top speed than a stepper motor and will be able to provide more torque at speed.

Advantages of Servo Motors

Servo motors offer several advantages over other types of motors, including:

- Precision Control: Servo motors provide precise control of position, speed, and torque, making them ideal for applications where accuracy and repeatability are critical.

- High Torque: Servo motors are designed to provide high torque at all speeds, which makes them well-suited for applications that require high starting torque and move loads at high speeds.

- Fast Response Time: Servo motors have a very fast response time, which makes them ideal for applications that require rapid acceleration.

- Wide Speed Range: Servo motors are capable of operating at a wide range of speeds, from very slow to very fast, without losing accuracy or precision.

Servo Motor Applications

Servo motors are used in a wide range of industrial and commercial applications that require precise control of motion, including:

- Robotics: Servo motors are commonly used in robotics for precise control of joint movements, as well as for grippers and end effectors.

- CNC Machines: Servo motors are widely used in computer numerical control (CNC) machines for precision positioning and motion control of cutting tools.

- Packaging Machinery: Servo motors are used in packaging machinery to control the movement of conveyor belts, as well as for the precise positioning and movement of packaging materials.

- Aerospace: Servo motors are used in aerospace applications for precise control of aircraft components, such as flaps and landing gear.

- Autonomous Guided Vehicles: Servo motors are used to power and steer the wheels in autonomous guided vehicles.

- Medical Equipment: Servo motors are used in medical equipment for precise control of medical devices, such as surgical robots, prosthetics, and other medical devices.

- Printing and Paper Processing: Servo motors are used in printing and paper processing equipment for precise control of paper feeding, cutting, and folding.

- Industrial Automation: Servo motors are used in a wide range of industrial automation applications, including conveyor systems, material handling, and assembly lines.

Servo Customizations

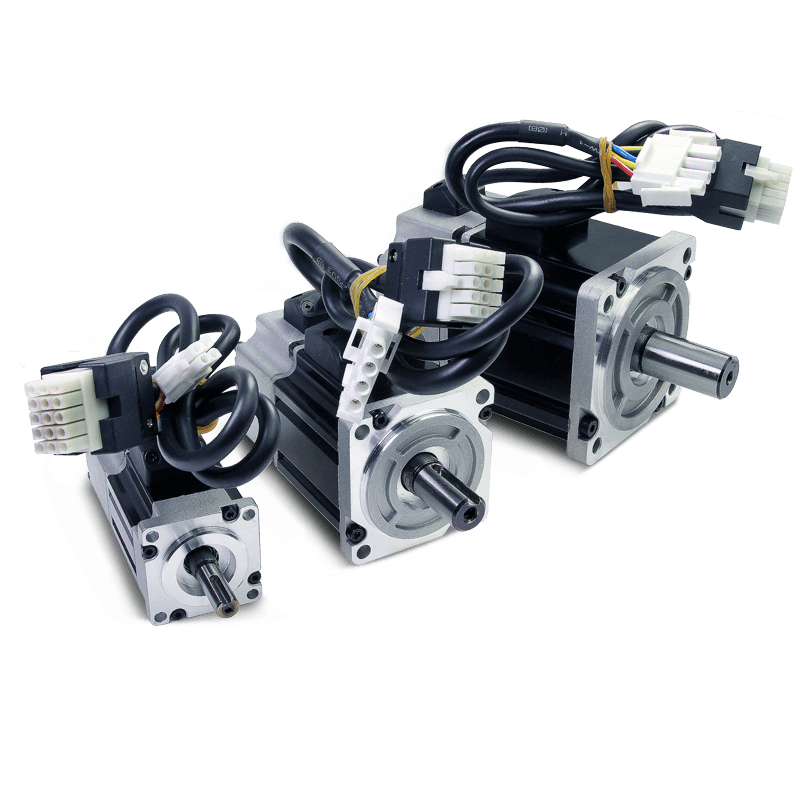

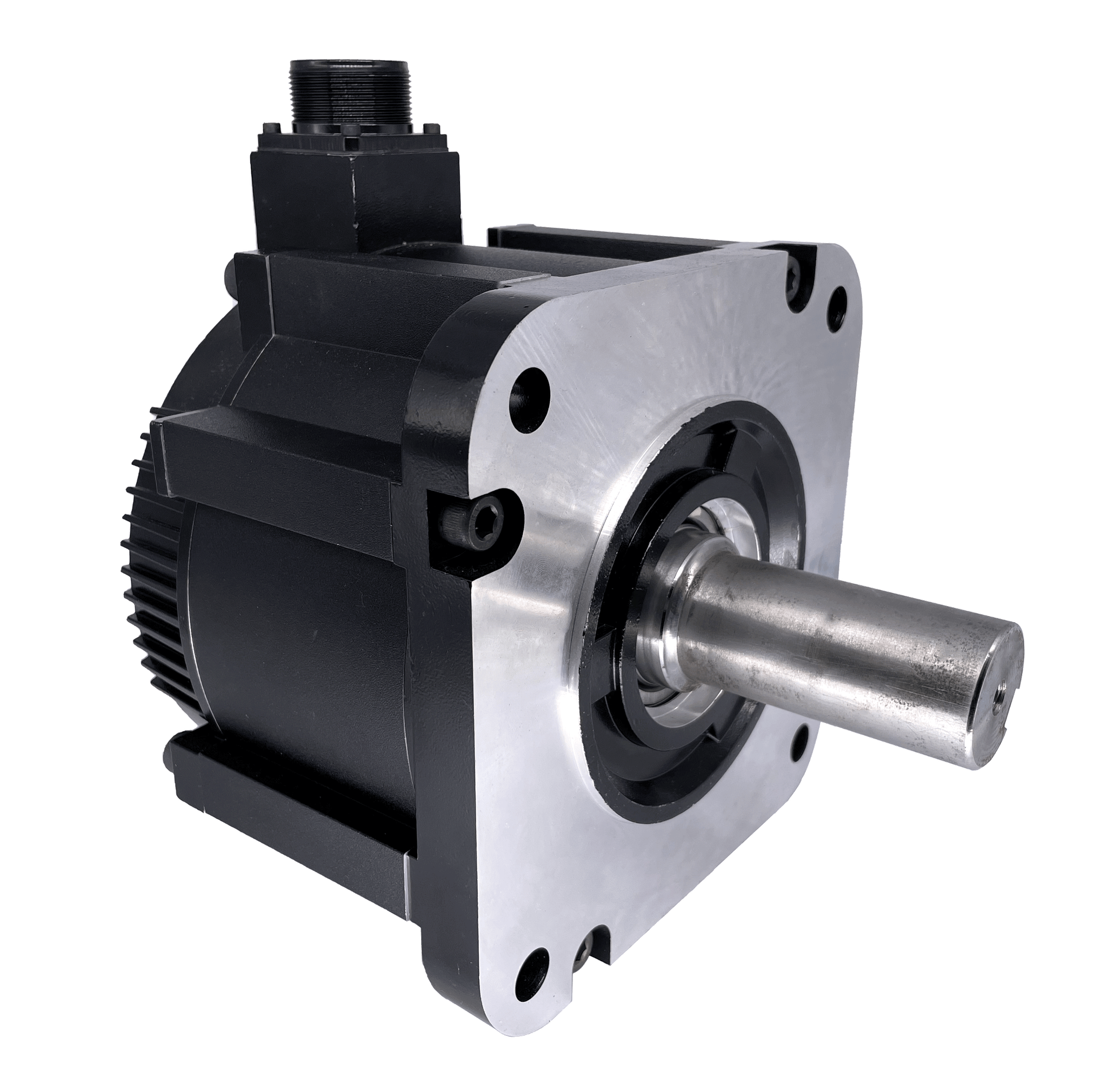

What sets us apart from other manufacturers is our extensive ability to optimize and customize our motors for your specific application needs. We can ensure that our motors are optimized to deliver the required performance for your specific application, whether it’s increasing torque at a specific speed range, reducing noise or vibration, or optimizing for minimal power consumption. We can customize the housing to match your application or replace an old motor.

Furthermore, we can create custom modifications to the motor’s lead wires and connectors, customized mounting brackets or motor housings for proper fit and alignment, or customized motor shafts with gears or pulleys to drive. Additionally, we can extend the motor’s capabilities with value-add components such as gearboxes, encoders, dampers, or custom electronics.

Utilize our in-house wiring and wire harness manufacturing capabilities to customize the wiring and cabling to your exact specifications. We can utilize a variety of different connectors up to your specifications, from standard MOLEX connectors to supplied proprietary connectors. We can stock extra inventory of your wire harness in case of spikes in demand. As well, we can provide support for Kaban Inventory systems upon request. Using one vendor doesn’t just make ordering easier, it makes it cheaper. We can ship the motor and the wire harness together reducing shipping time, costs, and complications. As well, by combining the motor and wire harness together we can offer more savings.