Designing and Manufacturing Miniature Stepper Motors

Designing and Manufacturing Miniature Stepper Motors

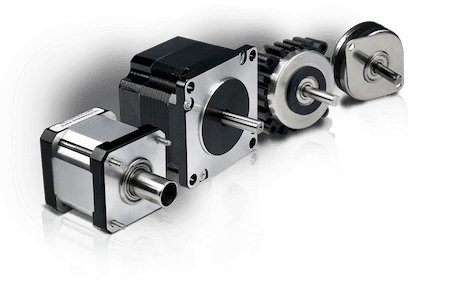

Miniaturization is a continual concern for many industries and one of the major trends over recent years. Everything from hand-tools to desktop and factory equipment, whether for production, testing, or everyday laboratory use, smaller and more powerful motors are needed for the motion and positioning systems. As equipment gets exponentially smaller, the challenges of designing devices to fit this equipment gets bigger.

Although companies have been designing and manufacturing small stepper motors for a long time, often small enough motors still don’t exist for many applications, forcing designs to be larger than necessary. And on the occasion when motors are small enough, they lack the specifications needed for the application, such as providing enough torque or speed needed for the device to be competitive in the market.

The sad option is to use a large-framed stepper motor and shrink all the other components around it, often requiring special brackets and mounting hardware. You can see that motion control in this small scale is the challenging bottleneck that forces engineers to compromise on the footprint of their device.

Making Miniature Motors

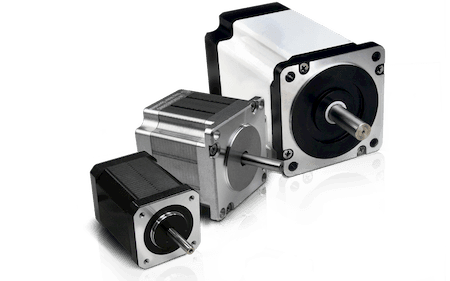

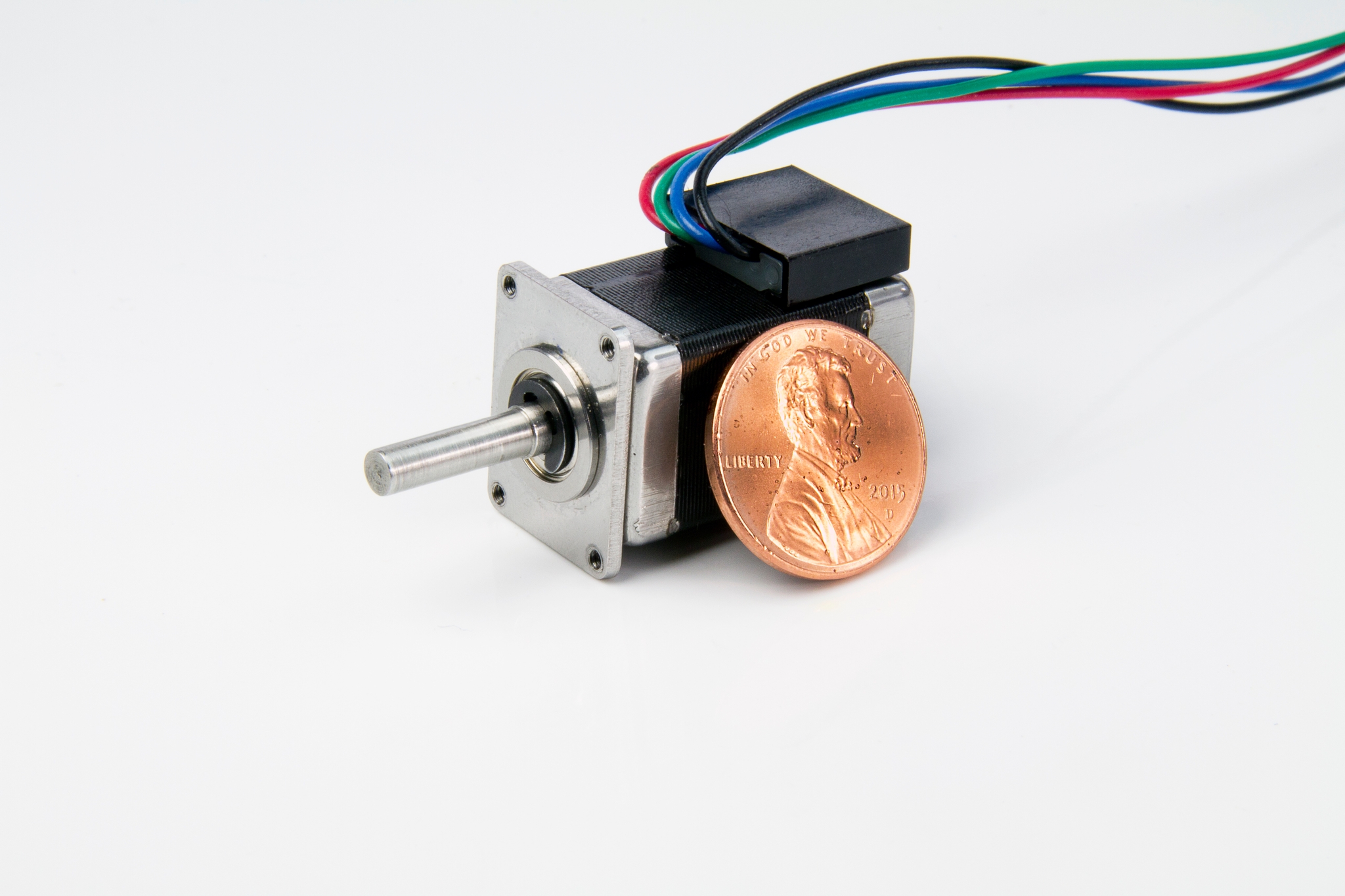

Miniaturization of stepper motors is challenging because the performance of the motor is directly related to its size, and as the size of the frame decreases so does the room for rotor magnets and windings. This not only affects the maximum torque output available, but also the speed at which the motor can operate. Of the manufacturers that have tried to create a NEMA 6 size hybrid stepper motor in the past, most have failed, therefore suggesting that the NEMA 6 frame size was too small to provide any useful performance.

This is where Lin Engineering comes in. By applying their experience with custom designs and their engineers’ expertise in several disciplines, they were able to succeed in creating a field-tested hybrid stepper motor technology where others failed. Not only does their NEMA 6-sized stepper motor deliver plenty of usable dynamic torque at high speed, it provides a high level of accuracy. Let’s discuss how they were able to design and manufacture such a device.

First of all, the company increased the step angle from a typical 1.8 degrees to 3.46 degrees, which allowed them to achieve nearly twice as much holding torque as the closest competing design, and nearly four times more holding torque—at up to 2.1 oz-in) then a conventional permanent magnet stepper motor of similar size (which tops out at 0.5 oz-in).

Further, a typical PM motor delivers about 20 steps per revolution—a step angle of 18 degrees. With the 3.46 degree motor, it is able to deliver 5.7 times higher resolutions than a typical PM motor. This higher resolution translates directly into higher precision for your application, providing the benefits of a hybrid stepper with none of the drawbacks of a PM motor. Add to this change in step angle a low inertia rotor design and the motor is able to achieve over 1 oz-in of dynamic torque at nearly 8,000 rpm, delivering similar speed performance as that of a standard brushless DC motor.

Application Focus

Miniature stepper motors can be used in a broad variety of industries that require compact size while maintaining high levels of accuracy. The medical industry, in particular, benefits from the cost-efficiency of miniature stepper motors for equipment from the emergency room to the patient’s bedside, to the laboratory.

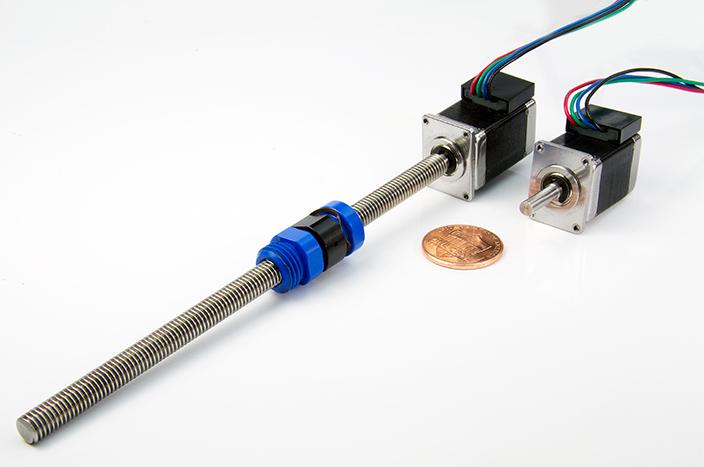

Presently, there is a lot of interest in handheld pipettes where miniature motors provide the high resolution needed for accurate dispensing of chemicals. These motors provide higher torque and higher quality for their size when compared to other products on the market used for these purposes.

For the laboratory, small linear stages that provide the benefits of the miniature stepper motor become a baseline for quality. Such stages are the hallmark of other industries as well. Anywhere compact size is an issue, these motors become the solution. Whether robotic arms or simple XYZ stages, stepper motors are easy to interface and provide open- or closed-loop functionality.

Conclusion

Miniature stepper motors are difficult to design and manufacture and often fail to compete with larger motors for applications. Providing a unique design approach, a hybrid stepper motor can be created and be the perfect candidate for many applications requiring tiny motors This is especially true in the field of medical devices and laboratory automation. Overall, applications that require a high degree of precision like miniature pumps, fluid metering and control, pinch valves, and optical sensor controls, can take advantage of this technology. The product can even be incorporated into motorized hand tools, such as electronic pipettes where Hybrid Stepper Motors were previously impossible to integrate.

News

Continue Reading

Solving Stepper Motor Design Challenges for Space Flight Applications

Space flight is challenging enough without having to worry about the operational limitations of the components used in the devices going to space. And since motors are a major component used in any motion system, specifications need to be on-target and reliable over a long period of time.

Selecting the Right Stepper Motor for Medical Applications

Medical applications often have the added concern that people’s lives may be in jeopardy if the equipment doesn’t work properly. Engineers working in this field of expertise must consider quality and longevity every step of the way. Therefore, when selecting a stepper motor for a medical device, engineers focus on the specific critical factors needed for the device prior to making a purchase. For example, a systolic pump may require high accuracy and a small footprint while a blood sampler used in a laboratory may need to be exceptionally quiet. As indicated, the requirements for stepper motors vary from device to device, yet there are several key factors that should always be considered.