linfinity linear actuator system

The LinFinity Linear Actuator is a system engineered to eliminate issues that plague ordinary linear actuators:

- Excessive friction and heat build-up

- Too much noise

- Degrading accuracy

- Short life span

- Required maintenance

- Patented Design

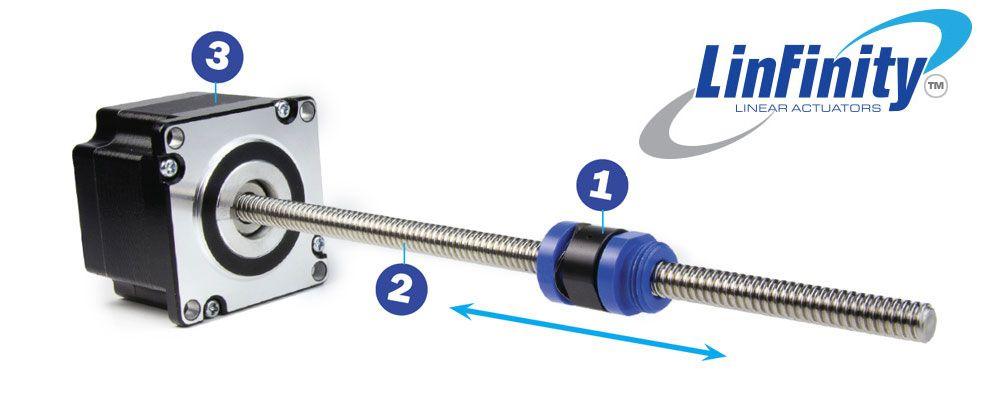

The LinFinity Linear Actuator system is composed of a patented LinFinity Nut, a highly polished lead screw, and a Lin Engineering stepper motor.

LinFinity Nut

The LinFinity Nut is an internally lubricated anti-backlash nut proven to last over 12 million inches of travel in a typical application without maintenance.

The patented design incorporates an internal grease reservoir which distributes a consistent layer of grease throughout the entire surface of the lead screw as the nut travels. The internal reservoir maintains hydrodynamic lubrication throughout the life of the product, which drastically reduces friction and thus increases the performance and longevity of the product.

Ordinary externally lubricated anti-backlash nuts act as a wiper: instead of distributing the grease evenly, they tend to push the grease out to the edges of the screw. This results in the grease drying out and ultimately leads to product failure.

EASY TO INSTALL AND ADJUST

Spring washer holds the tension ensuring zero backlash is maintained throughout the life of the product.

Once the nut is installed on the lead screw the internal grease reservoir can be filled from the outside.

The torque can be adjusted without removing the nut from the leadscrew. The anti-backlash tension can be adjusted simply by rotating the black nut against the spring washer to obtain the desired drag torque.

Less friction means less heat is being generated. LinFinity reduces heat build up by at least 20% compared to the closest competing design. Heat leads to premature failure.

Ordinary externally lubricated nuts tend to increase friction throughout the life of the product. Friction causes excessive noise. LinFinity maintains low friction throughout its lifespan and does not generate more noise with age.

Lower heat and reduced friction along with even distribution of grease result in the overall life of the Linear Actuator system to increase.

Leadscrew

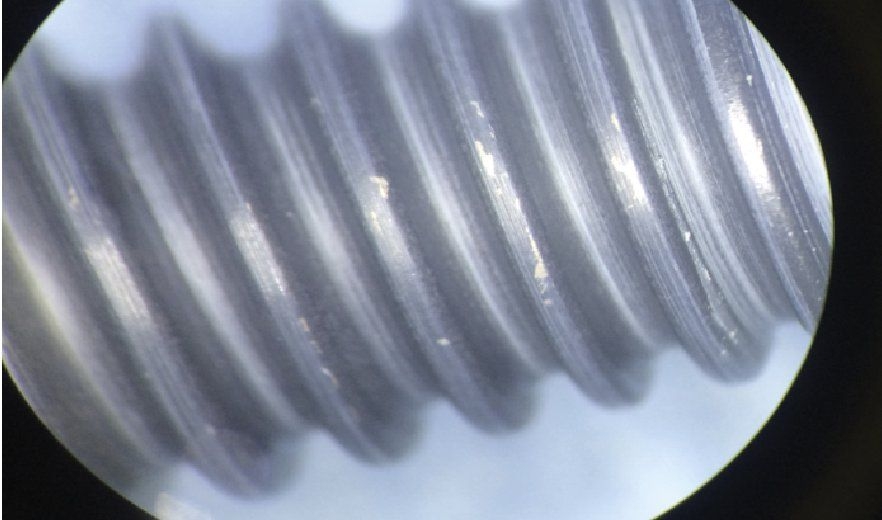

PTFE coated leadscrews are often used to reduce friction. This function well in many applications, however, PTFE coating may not be suitable for certain applications which demand constant cycling.

We’ve experienced noticeable coating damage while constantly cycling an anti-backlash nut over a PTFE coated leadscrew. The damage often occurs within one million inches of travel. And once the coating is compromised, further damage occurs at accelerated rate. This occurs because the metal surface of the leadscrew has to be roughened to accept the PTFE coating. And when the coating fails, the anti-backlash nut is exposed to the rough surface of the metal, which in turn accelerates the wear of the nut.

The LinFinity Nut glides on a highly polished leadscrew on a thin layer of grease. This makes LinFinity Nut suitable for even the most demanding applications. Polished leadscrews lets us achieve over 12 million inches of travel with no maintenance required; more than any other product we’ve tested.

Video Demonstration

Ready to start on your next product development project?

Let us know how we can help.