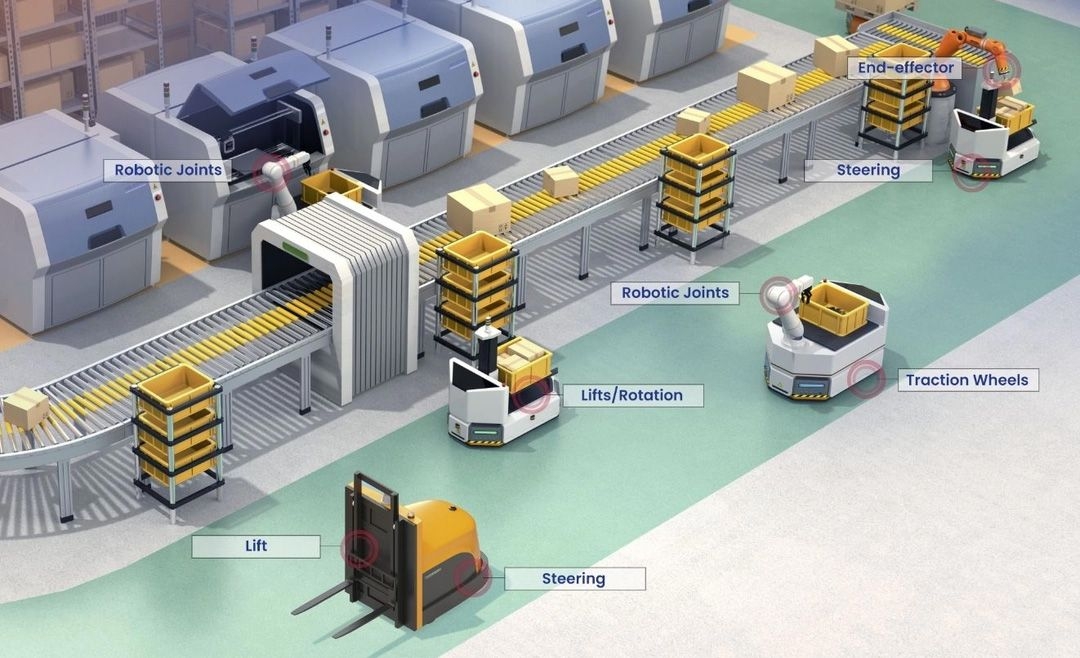

autonomous guided vehicles agv

We Design, Engineer, and Manufacture DC motors for the AGV & AMR market. We can quickly assemble motor prototypes so that you can start prototyping your new product with minimum downtime. We can start with a few motors and ramp up to 10 million motors if needed, all while providing ongoing product support and confidence that you will get a reliable and consistent product on time and within budget.

Lin Engineering is your one-stop shop for motion control solutions. We make a variety of custom motors including stepper, hybrid stepper, BLDC, Servos, frameless, slotless, linear actuators, and more. Our team of engineers will help you find an appropriate motor for your application and optimize the motor for the best performance within your specific application. Lastly, we can customize the motor to ensure it seamlessly integrates into your application.

- ISO9001 and AS9100 Compliant

- High Reliability and Consistent Performance

- Customized and Optimized for Your Specific Application

- US Based Support & Manufacturing

- Cost-effective motor solutions

Application Examples

Commonly Used Products

Motorized Traction Wheels

Lin Engineering’s motorized traction wheel solutions are designed to deliver compact, easy-to-use, and more efficient traction solutions.

- In-Wheel motors are gearless, high pole count BLDC motors specifically designed for the direct drive of low payload vehicles, up to 500 Watts per wheel.

- Servo-Wheel motors are geared and gearless servo motors with greater power density and efficiency. They are best suited for medium-to-high payload vehicles and are available with power up to 2 Kilowatts. These wheels can accommodate multiple-sized motors.

Servo-wheel motors are available with optional brakes, encoders or dual encoders, as well as your choice of planetary, belt, or spur gear transmissions.

Outer Rotor Motors

Outer rotor motors are different from typical motors as they have the rotor and stator switched. By doing this the outside of the motor will turn instead of the shaft. This can be helpful in situations where direct drive is needed.

Features:

- Low noise

- Long Life

- Energy Saving

- High Torque

- Low Noise

- Large Motor Inertia

Servo Motors

Lin Engineering’s advanced Servo motor technology is at the core of the most demanding vehicles manufactured by industry-leading warehouse automation OEMs. Lin Engineering’s servo motors feature:

- Segmented winding technology for maximum power density

- Epoxy-encapsulated stator for optimal heat dissipation

- High energy skewed magnets for greater peak torque and speed control

- Double-bonded magnets and precision balancing for smooth, safe operation

- High-capacity bearings for long life with high radial loads

- IP65 Rating for durability

- Multiple encoder options are available

- Servo Motor Sizes: 40 mm to 180 mm

- Available in AC or DC

Servo Motors

Why Choose Lin Engineering?

We understand that not everyone can be an expert in Motion Control. The goal is to find a motor that will move an object from point A to point B. But often there’s more to consider than just Speed and Torque requirements. Engineers need to consider mounting structures, space allotment, noise, vibration, heat, component materials, windings, and much more. But not all companies have in-house expertise related to motion control or motor design.

We are a “Solution First” company that not only supplies the motors that you need, but also provides the Engineering expertise needed to find, optimize, and customize the right motors that will perform within your system optimally and reliably.

Why Choose Lin Engineering?

OEM Motors Optimized For Your Application

Quick Prototype Turnaround

Small Batch to Large Volume Production

US Based Support and Manufacturing

Fast Prototyping

Here at Lin Engineering, we understand keeping your project progressing is important; that’s why we offer quick prototyping turnaround times, as quick as 7 days. This is possible due to the modular design of our motors. Don’t get caught waiting for the parts you need, using our rapid prototyping tool you can customize and order the motors you need fast.

US Based Manufacturing & Support

Everything starts with our facility in Morgan Hill, California which is conveniently located in the heart of Silicon Valley. Not only do we have a full Engineering staff, but there is also a local Quality team, Applications, Sales, Customer Service, and so much more. The crown jewel of it all? A California-based manufacturing facility that proudly assembles and customizes motors in the USA.

For added support, we have a nationwide team of Applications Engineers and Account Managers that can provide you with the benefits of localized support.

Applications Support

Our US-based engineering team is excited to help solve your motion control problems or issues. Our engineers have helped solve motion control issues for a wide array of industries as well as helped companies design and build new products. Being exposed to so many different projects has helped our team to think outside of the box when looking for a solution.

Engineering Support

For OEM Motor Projects, we’ll work directly with your engineering team throughout the design phase of your project to ensure the best overall system optimization and motor fit while avoiding over-engineering. Our experienced engineers can help you eliminate costly complexities and over-designing while keeping in mind future developments and improvements.

Motors Capable of Withstanding Extreme Enviroments

Vacuum Rated Motors

IP Rated Motors

Hot & Cold Motors

These motors are designed and manufactured to operate in unique environments for specific applications. Vacuum-rated motors, for example, are necessary for environments where out-gassing needs to be minimized such as vacuum chambers, space applications, and clean room environments. IP (Ingress Protection) rated motors are perfect for applications exposed to humidity, water, oil, and other various debris. We also carry motors that are specifically designed to operate in extreme hot and cold temperatures.

- Vacuum and Ultra High Vacuum Grade Motors

- Ingress Protection (IP) Rated Motors

- Hot/Cold Temperature Operating Motors

Speak with one of our motion control experts about your next project.