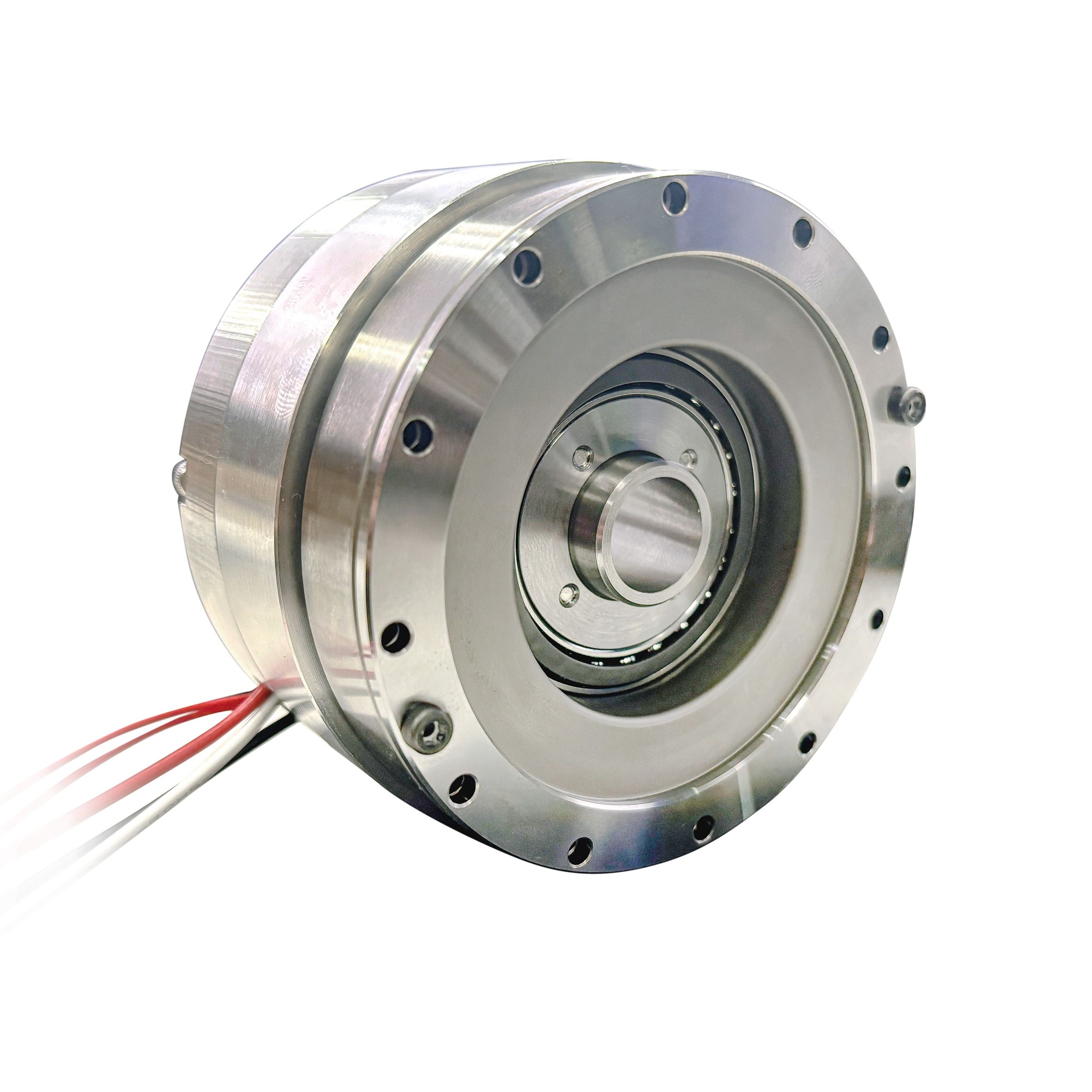

PC-T085CN008-48A-SA-80

Frameless Motor Rotary Actuator

Specifications:

- 94mm Frame Size

- 53mm Length

- 24Nm Rated Torque

- 48VDC Bus Voltage

Features and Benefits:

- High torque to weight ratio

- Integrated strain wave gear

- Large thru-bore shaft

- Compact & lightweight

- Encoder, hall sensor and thermistor available

Features and Benefits

This rotary servo actuator pairs a strain wave gear with a performance-matched Lin Engineering frameless torque motor, delivering precise, high-torque motion in a compact, low-profile form factor. The actuator features zero backlash, an 80:1 gear ratio, and high torque density. A large center through-hole allows for easy routing of cables, tubing, or optical paths directly through the axis of rotation, simplifying system design and integration.

Dimensional Drawing

Specifications

| Bus Voltage (Vbus) | 48 VDC |

| Rated Torque (Trtd) | 24 Nm |

| Peak Torque (Tpk) | 51 Nm |

| Max Cont. Current (Icont) | 5.2 A |

| Peak Current (Ipk) | 13.29 Arms |

| Rated Output Speed (Nrtd) | 44 RPM |

| Starting Friction | 0.23 Nm |

| Gear Ratio | 80:1 |

| Gear Efficiency | 80% |

Applications

This actuator is an ideal fit for advanced robotic systems, including AGVs, AMRs, cobot arms, humanoid robots, exoskeletons, and surgical robots. Its compact cylindrical design, zero backlash, high torque density, and large center through-hole make it especially well-suited for applications where precision, efficiency, and space optimization are critical. Whether you're routing cables through a humanoid joint or enabling smooth, controlled motion in surgical or wearable robotics, this actuator delivers the performance and reliability your system demands.

Why Choose Lin Engineering?

Choosing Lin Engineering as your supply chain partner means gaining access to a trusted leader in motion control with decades of expertise in designing and manufacturing high-performance motors. We offer tailored solutions, from prototype to high-volume production, ensuring that your motors are optimized for your specific application. Our commitment to quality, customization, and on-time delivery is unmatched, and our in-house engineering and support teams work closely with you to meet your technical and operational needs. With our ability to scale production and provide motors with precision performance, Lin Engineering ensures seamless integration into your supply chain for long-term success.

- USA-based Engineering and Manufacturing

- USA-based Engineering and Manufacturing

- Fast-track Prototyping

- Off-the-shelf motors and fast prototype turnaround

- Collaborative Engineering Support

- We can work closely with your team to create a customized solution for your specific application

- Engineered for Manufacturability

- Customized, plug-and-play motor solutions

- Sustainable Supply Chain

- Long-term motor manufacturing support throughout the lifecycle of your product

- Scalable Production

- From 10 motors to 10 million motors

- Vertically Integrated

- We manufacture our own components, ensuring supply chain stability and on-time delivery