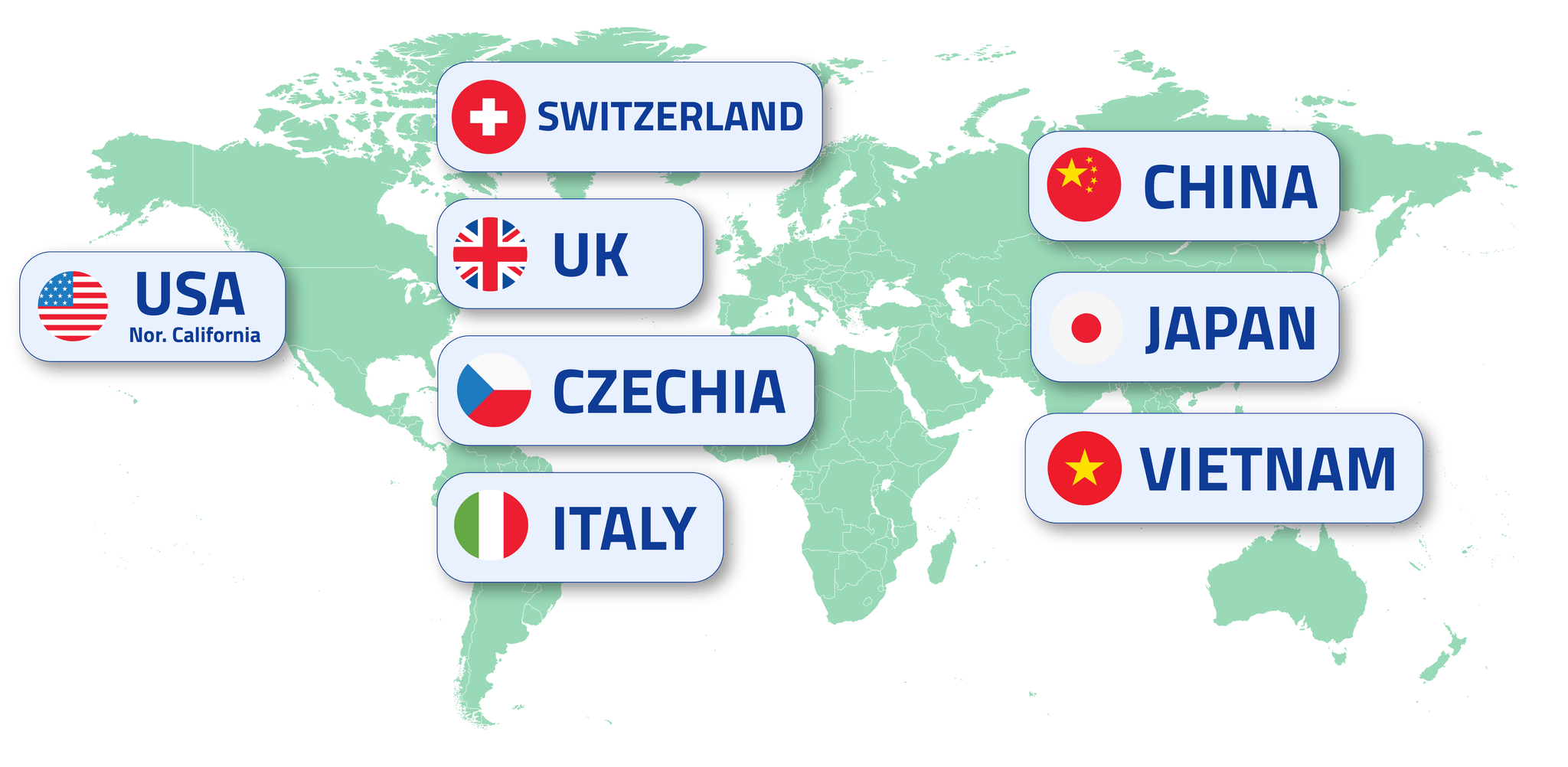

Global Manufacturing Footprint

Global Footprint

Lin Engineering has a strong global footprint with 1.5 million square feet of manufacturing space across eight facilities, including additional locations in Europe and Asia. This extensive network enables scalable production, ensuring efficient delivery and support for customers worldwide.

How does that benefit your operation?

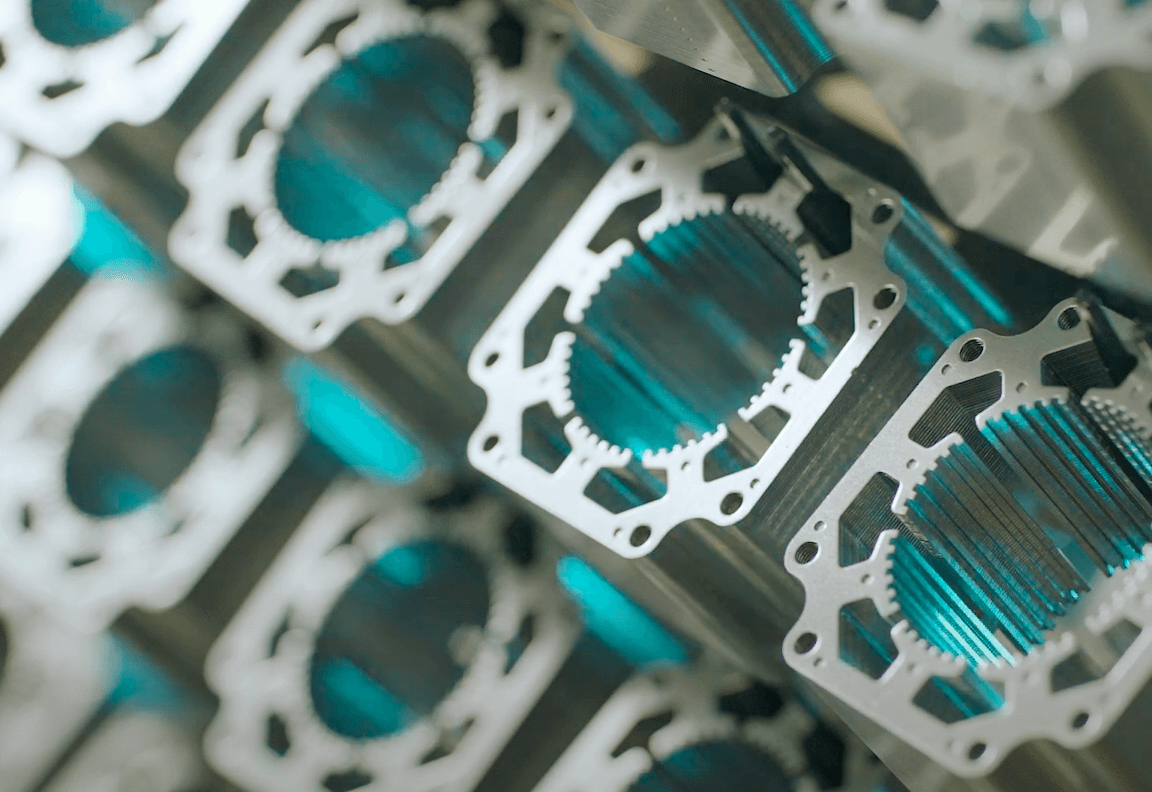

Vertically Integrated

We manufacture our own components, ensuring supply chain stability and on-time delivery.

With a robust global manufacturing footprint, Lin Engineering’s vertically integrated operations enhance supply chain stability and reliability, ensuring on-time delivery for your projects. By producing many sub-components in-house, we reduce dependency on external suppliers, minimizing risks from outside disruptions. This means a smoother, more predictable path from design to delivery—keeping your timelines and production goals on track.

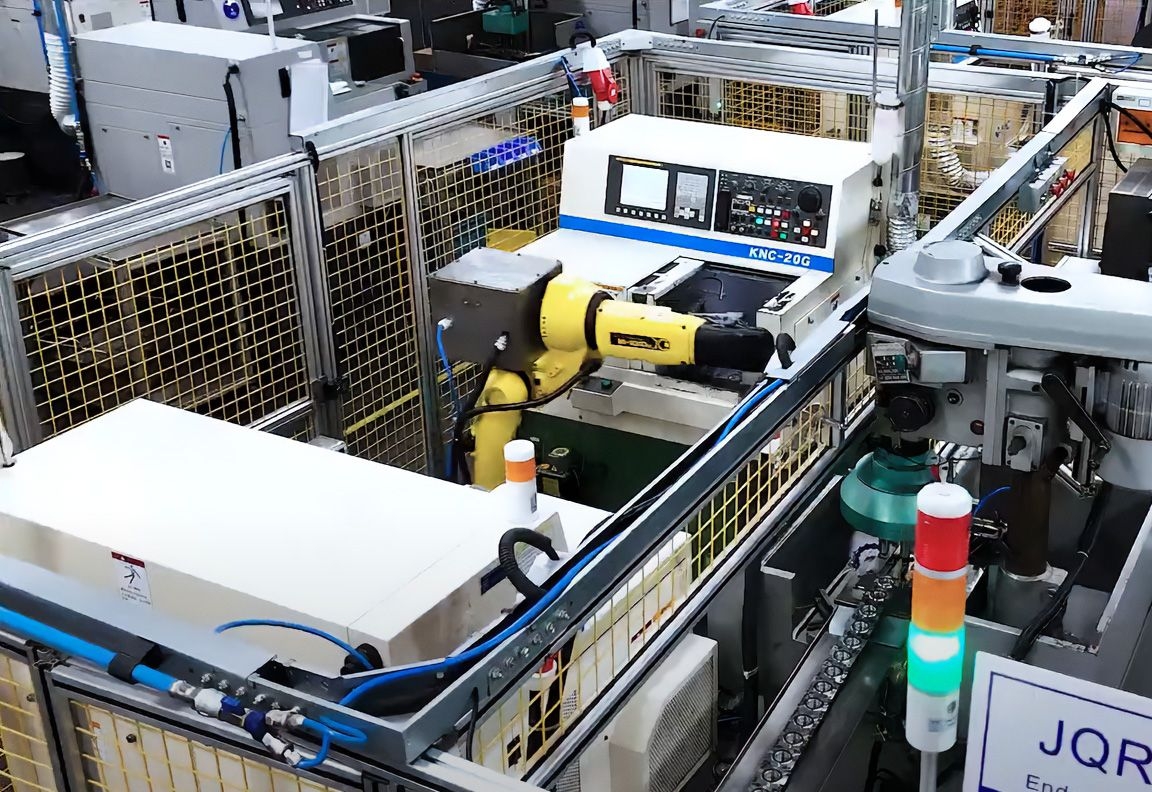

Scalable Production

From 10 motors to 10 million motors

Lin Engineering’s global manufacturing footprint means we can scale production seamlessly to match your demand—from small-batch orders to high-volume needs. This flexible capacity supports you through every phase, from initial prototypes to full-scale production. As your demand grows, our reliable, scalable motor supply chain adapts with you, ensuring continuous support and collaborative improvements for optimal performance, giving you a dependable partner to evolve with your business.

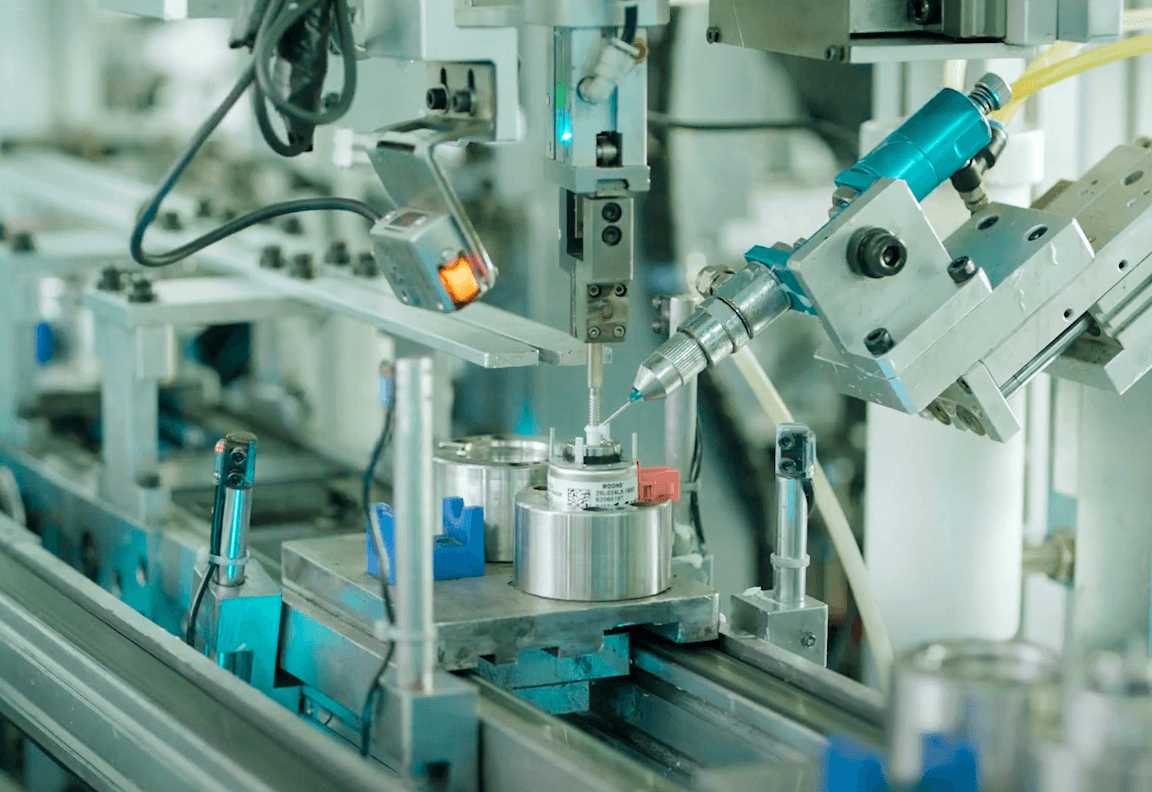

Sustainable Supply Chain

Long-term motor manufacturing support throughout the lifecycle of your product

Lin Engineering’s global manufacturing footprint supports a sustainable, resilient supply chain, crucial for long-term product success. Our extensive facilities and vertically integrated operations help mitigate risks like component obsolescence and supply chain disruptions. With Lin, you’re assured of motor availability throughout your product's lifecycle. We custom-design motors to your specifications, assign a unique part number for exclusive access, and provide ongoing support. This sustainable supply chain approach secures the long-term availability of components, letting you focus on driving innovation and growth with confidence.

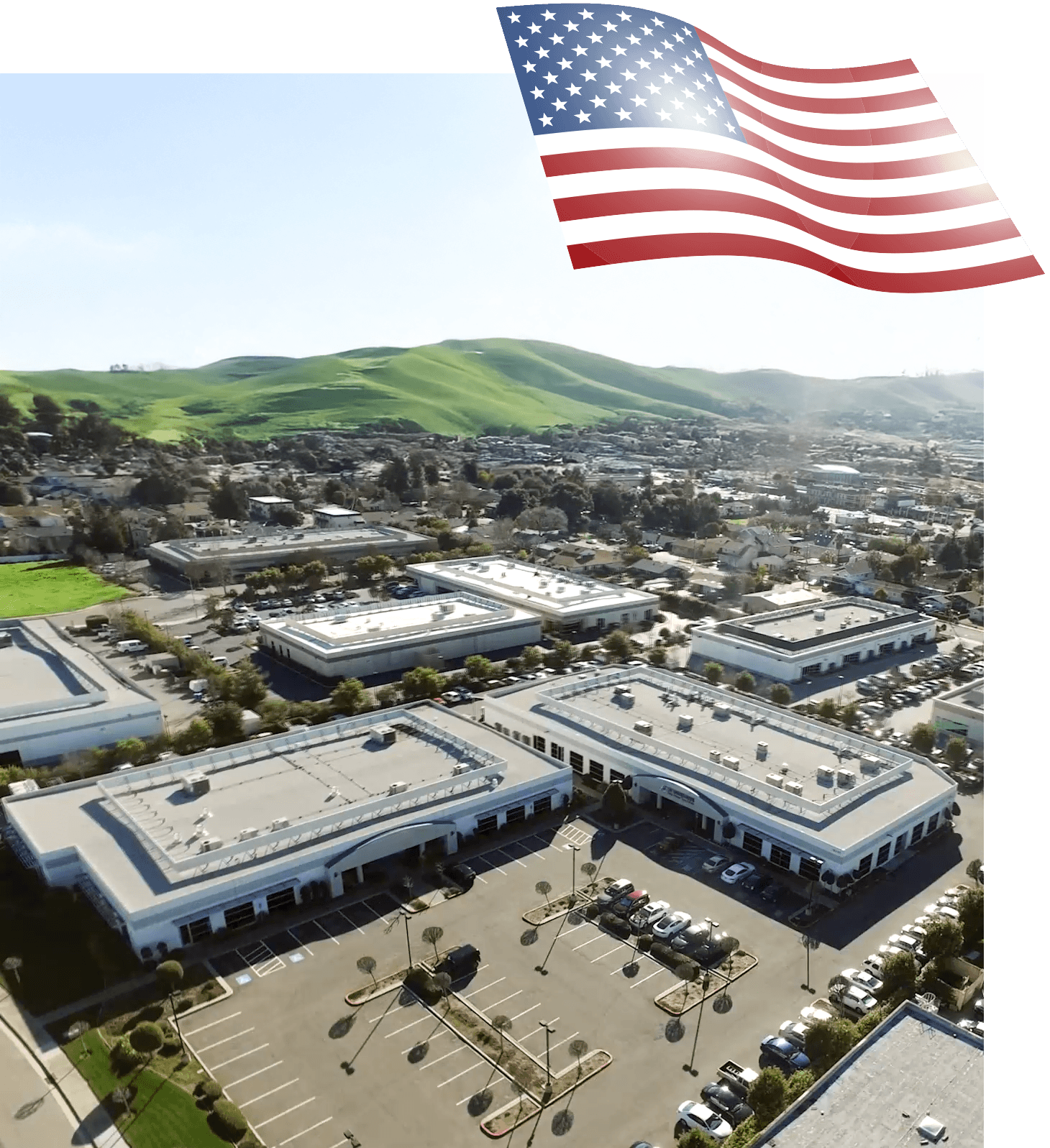

USA-based Production

Motors Proudly Assembled in the USA

Lin Engineering offers USA-based support, engineering, and assembly from our Northern California facility, ensuring responsive service and seamless collaboration throughout your project. Our local team works closely with your engineers to develop and customize motor solutions tailored to your specific application needs. With in-house assembly and production capabilities, we can efficiently handle everything from prototypes to mass volume orders—all while reducing lead times and ensuring top-tier quality. Partnering with Lin Engineering means you get direct access to expert support, faster turnaround times, and the reliability of American-assembled motors built to perform.

Ready to start on your next product development project?

Let us know how we can help.