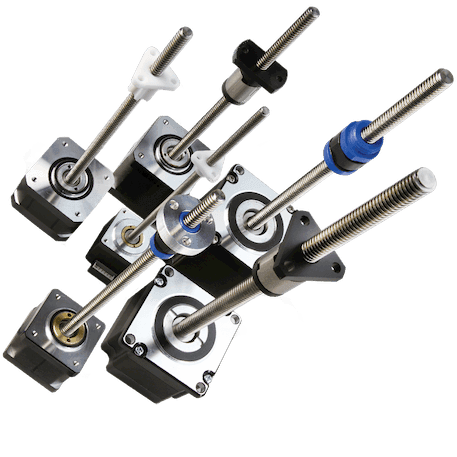

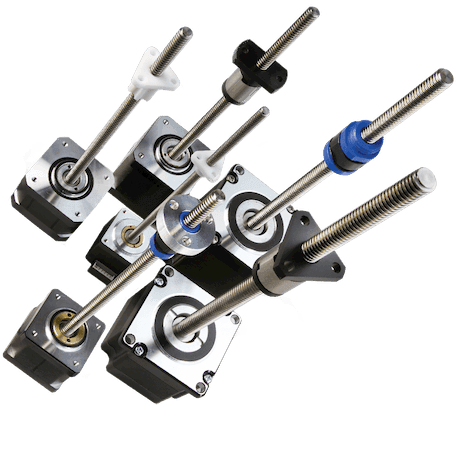

linear actuators

Lin Engineering designs and manufactures hybrid stepper motor powered linear actuators. Lin's product line includes both External Nut (LE) and Non-Captive (LN) configurations to meet the needs of various applications. Lin Engineering linear actuators are designed and manufactured to deliver the highest quality and performance. Whether you need a standard linear actuator or a custom solution, Lin Engineering has the expertise and resources to meet your needs.

Available Products

rapid prototype configurator

Experience seamless and efficient prototyping with Lin Engineer's Rapid Prototyping Configurator. Tailor and order LE and LN linear actuators effortlessly, unlocking a world of precise motion control for your projects. Enjoy the added benefit of quick delivery, ensuring you get your custom linear actuators fast.

Configured Solutions

Learn how we’ll work with you and your team to help motors that fit your specific application.

Learn More