Revolutionizing the Food and Beverage Industry: Exploring New Robots in Food Preparation, Serving, and Delivery

Revolutionizing the Food and Beverage Industry: Exploring New Robots in Food Preparation, Serving, and Delivery

The food and beverage industry is one of the largest and most dynamic sectors globally, with new trends and demands continuously shaping the market. Technological advancements have brought about several changes in the industry, with robotics being one of the most impactful. Robots have been introduced to perform various tasks, ranging from food preparation to serving and even delivery. We will examine the latest advancements in the food and beverage industry regarding robotic technology and the benefits that come with them.

Robotic Food Preparation

The introduction of robotic technology in the food and beverage industry has transformed the way food is prepared. Traditionally, food preparation has been a time-consuming and labor-intensive process, involving the use of several kitchen tools and equipment. However, with the introduction of robotic technology, food preparation has become more efficient and cost-effective.

The new robots in the industry can handle several tasks, ranging from chopping and slicing to mixing and cooking. These robots are designed to work alongside human employees, with minimal supervision, and can handle large quantities of food. For instance, Moley Robotics has developed a robotic kitchen that can prepare thousands of recipes with precision and speed, reducing the time and costs associated with food preparation.

The advantages of robotic food preparation are numerous. Firstly, robots offer precision, which is helpful in the food and beverage industry. They can measure and weigh ingredients with high accuracy, ensuring that the final product is of high quality. Secondly, robots are incredibly fast, reducing the time taken to prepare food significantly. This can help to increase the output of a kitchen, ensuring that orders are fulfilled promptly. Finally, robots offer consistency, which is vital in the food and beverage industry. With robots, the final product will always have the same quality, regardless of who is preparing it.

Robotic Serving

The traditional method of serving food and drinks in the food and beverage industry has always involved human servers. However, with the introduction of robotic technology, robotic serving has become a reality. Robots are now being used to serve food and drinks to customers in restaurants, cafes, and other food establishments. These robots are designed to be interactive and engaging, with some even programmed to communicate with customers.

For example, the robot Servi developed by Bear Robotics is designed to serve food and drinks to customers and navigate through crowded restaurants. Servi is equipped with sensors that help it detect obstacles, enabling it to navigate through tight spaces easily. Additionally, Servi is designed to interact with customers, engaging them in conversation and providing them with a unique dining experience.

Robotic serving has several advantages. Firstly, it can help to reduce labor costs, as robots do not require wages or benefits. This can help food establishments to save money, which can be redirected toward other areas of the business. Secondly, robotic serving can improve service speed. With robots, food and drinks can be delivered to customers faster, reducing waiting times and increasing customer satisfaction. Finally, robotic serving can enhance customer experience, providing customers with a unique and exciting dining experience.

Robotic Delivery

Robotic delivery is a new and exciting development in the food and beverage industry, providing an innovative solution to food delivery challenges. With the increasing demand for food delivery services, the use of robots to deliver food and drinks has become more prevalent. These robots are designed to navigate through city streets and traffic, delivering orders to customers efficiently and effectively.

For instance, the robot developed by Starship Technologies is equipped with sensors and cameras that enable it to navigate through city streets and avoid obstacles. It can be programmed to deliver orders to specific locations, and customers can track the progress of their orders through a mobile app. The robot can travel up to 4 mph and deliver orders within a two-mile radius, making it ideal for delivering food and drinks to customers in urban areas.

Robotic delivery has several benefits for both food establishments and customers. Firstly, it can help to reduce delivery costs, as robots do not require wages or benefits, making it a cost-effective delivery option. Secondly, robotic delivery can improve delivery speed, as robots can travel faster and more efficiently than human delivery drivers, reducing delivery times and increasing customer satisfaction. Finally, robotic delivery can enhance customer experience, as customers can track the progress of their orders and receive real-time updates on delivery status.

Lin Engineering Custom Robotic Solutions

In addition to the many benefits that robotic technology brings to the food and beverage industry, custom motion control solutions from Lin Engineering can further enhance these advantages. Lin Engineering specializes in creating custom motion control solutions for various industries, including the food and beverage industry. Their products include steppers and brushless motors, linear actuators, servos, motorized traction wheels, and more that are designed to meet the specific needs of their customers.

For the food and beverage industry, Lin Engineering can provide motion control solutions that improve the performance and efficiency of robotic equipment. These solutions can enhance the precision and speed of robotic food preparation, serving, and delivery, ensuring that food establishments can meet the demands of their customers.

By partnering with Lin Engineering, food and beverage robotics manufacturers can benefit from custom motion control solutions that are tailored to their specific needs. These solutions can help to reduce costs, improve efficiency, and enhance customer experience, making them a valuable addition to the food and beverage industry's robotic technology.

In conclusion, the food and beverage industry is continuously evolving, with new technological innovations being introduced to enhance efficiency and reduce costs. Robotic technology has played a significant role in the industry, with robots being used to perform tasks such as food preparation, serving, and delivery. The benefits of robotic technology in the industry include improved efficiency, reduced labor costs, and enhanced customer experience. However, the limitations of these robots include their high cost of acquisition, maintenance, and the need for regular updates to keep them up to date with the latest technology. With continued research and development, robotic technology has the potential to revolutionize the food and beverage industry, making it more efficient, profitable, and customer-oriented.

News

Continue Reading

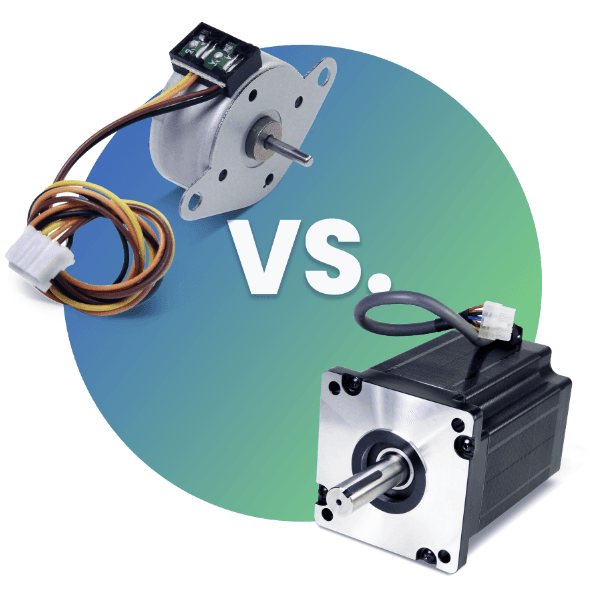

Choosing the Right Stepper Motor: PM Stepper or Hybrid Stepper?

When it comes to selecting the right stepper motor for your application, there are two primary types to consider: permanent magnet (PM) stepper motors and hybrid stepper motors. Both types have their advantages and disadvantages, and the choice ultimately depends on your specific application requirements.

Powering Ahead: A Comprehensive Look at How Motorized Traction Wheels Work

This article explores the design, operation, and practical applications of motorized traction wheels.