Choosing the Right Stepper Motor: PM Stepper or Hybrid Stepper?

Stepper motors are widely used in various applications that require precise control of motion, such as in robotics, 3D printing, CNC machines, and medical equipment. There are two main types of stepper motors: Permanent Magnet (PM) stepper motors and Hybrid stepper motors. In this article, we will discuss the differences, advantages, and when to use a PM stepper motor or a Hybrid stepper motor.

What is a PM Stepper Motor?

Permanent Magnet stepper motors, also known as "tin can" stepper motors, are the simplest type of stepper motor. They consist of a rotor with permanent magnets and a stator with two coils. When current is applied to one of the coils, it generates a magnetic field that attracts the permanent magnet rotor towards it. PM stepper motors are typically less expensive and simpler in design than hybrid stepper motors.

Advantages of PM Stepper Motor

- Lower Cost: PM stepper motors are less expensive than hybrid stepper motors, making them a good choice for applications where cost is a major consideration.

- Simpler Design: PM stepper motors have a simpler design than hybrid stepper motors, making them easier to manufacture and maintain.

- Good Low-Speed Performance: PM stepper motors provide good low-speed performance, making them ideal for applications that require position control at low speeds.

When to use a PM Stepper Motor

PM stepper motors are commonly used in small robotics projects, cameras, and toys where the volume is very high. They are also used in medical equipment, scientific instruments, and laboratory automation that require precise control at low speeds such as high-precision microscopes and automated pipetting systems. As well they can be used in automotive applications such as electric power steering systems, throttle control, and braking systems.

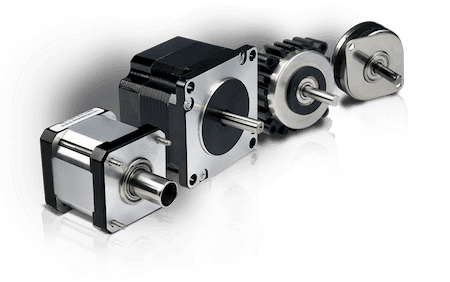

What is a Hybrid Stepper Motor?

Hybrid stepper motors are more complex than PM stepper motors. They typically use a sintered magnet which provides a higher magnetic flux over bonded magnets used in PM motors. They also include laminated stacks with precise teeth profiles in the rotor and stator that can create smaller step sizes. When the coils are energized, the rotor teeth are magnetically attracted to the stator teeth and move incrementally according to its natural step size. This furthers their ability to provide more precise control of the motor’s movement.

Advantages of Hybrid Stepper Motors

- High Torque: Hybrid stepper motors provide high torque output, making them ideal for applications moving large loads.

- Precise Positioning: Hybrid steppers can have a step size of 0.45°, making them great for precise positioning.

- Repeatable Movement: Hybrid steppers have very repeatable movement, making them perfect for applications with repetitive motions.

When to Use a Hybrid Stepper Motor

Hybrid stepper motors are suitable for applications that require high torque output where space is limited. Their high holding torque can maintain position without the use of a brake, and their small step size allows for precise positioning. Even without the use of a position feedback sensor, stepper motors can reliably achieve repetitive motions with a high level of accuracy.

Hybrid stepper motors are commonly used in CNC machines, 3D printers, industrial automation, and material handling systems. They are also found in robotics and pick-and-place machines that require high precision and accuracy.

Hybrid stepper motors can also be used in applications where a PM stepper motor needs to be more powerful or reliability is a concern. Stainless steel bearings provide low friction even while rotating at high speeds.

Differences between PM Stepper Motors & Hybrid Stepper Motors

While both PM stepper and hybrid stepper motors can move in increments, PM stepper motors have a simpler design while hybrid stepper motors offer a smaller step size and higher torque density. When choosing between a PM stepper motor and a hybrid stepper motor, there are several factors to consider:

- Torque: Hybrid stepper motors provide higher torque output than PM stepper motors.

- Cost: PM stepper motors are typically less expensive than hybrid stepper motors.

- Resolution: Hybrid stepper motors have smaller step sizes.

- Maintenance: Hybrid stepper motors tend to have a longer life.

- Load: Hybrid stepper motors typically have a higher load rating due to the steel ball bearings used in their construction.

- Control: The type of control system used to operate the motor should be considered.

PM stepper motors and Hybrid stepper motors are two main types of stepper motors used in a variety of applications that require precise control of motion. While PM stepper motors are simpler and less expensive, hybrid stepper motors provide higher torque output and can operate at higher speeds.

When choosing a stepper motor, one should review the specific requirements of the application. Factors such as cost, torque, speed, precision, load, and control should be considered to ensure the right type of stepper motor is selected for the application.

News

Continue Reading

Surgical Robot Stepper Motor Case Study

When selecting a stepper motor for an application in the medical industry, many factors need to be considered. These applications, whether they are pumps, life science-related, or general lab automation, are often used in environments that are crucial to patients and technicians alike. In this case study, we will take a sneak peek into an application involving surgical robotics!

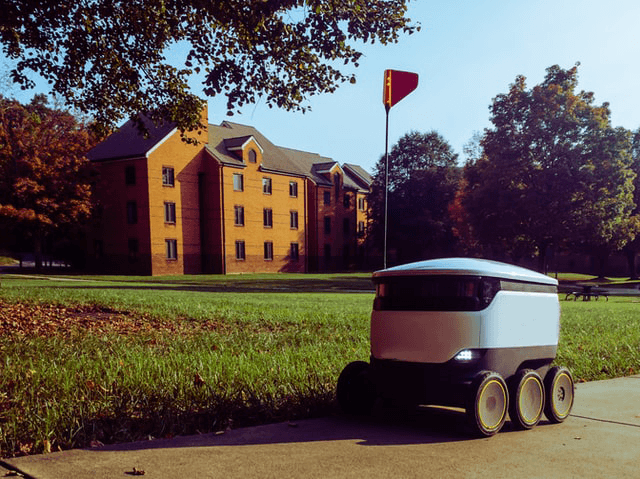

Revolutionizing the Food and Beverage Industry: Exploring New Robots in Food Preparation, Serving, and Delivery

Robotic advancements are dramatically reshaping the landscape of the food and beverage sector. This article delves into the transformative impact of robots on aspects of the industry, including food preparation, service, and delivery logistics.